Method of forming bright metallized film laminate

a technology of metallized film and bright color, applied in the field of bright metallized film laminate, can solve the problems of shortening the processing time associated with metallizing three-dimensional articles, disadvantageous depositing of metal directly onto articles only after the article has been formed, and customized applications, etc., to achieve superior optical and deformation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0069] The method can include the following steps: casting an acrylic primer layer (TEDLAR 68070 from DuPont) at a dry thickness of 0.5 mil on FLUOREX.RTM. A; casting a polyurethane layer (SU 6729 from Stahl) at a dry thickness of 0.5 mil on the dried primer layer; depositing a layer of indium at an OD of 1.15 on the polyurethane surface through vacuum deposition; making an adhesive composite by casting an acrylic material (ELVACITE 2009) at a dry thickness of 0.5 mil on a 2 mil PET; casting a polyurethane (ADH 222 from Novacote) at a dry thickness of 0.5 mil on dried ELVACITE 2009; adding a PET film to the indium surface and press polishing; removing the PET from the indium surface and bonding the ADH 222 surface of the adhesive composite onto the indium surface; removing the PET from the adhesive composite; bonding the composite to a 20 mil ABS through a hot nip at between 330.degree. to 380.degree. F.

[0070] The preferred embodiments of the invention and the method of making them ...

first embodiment

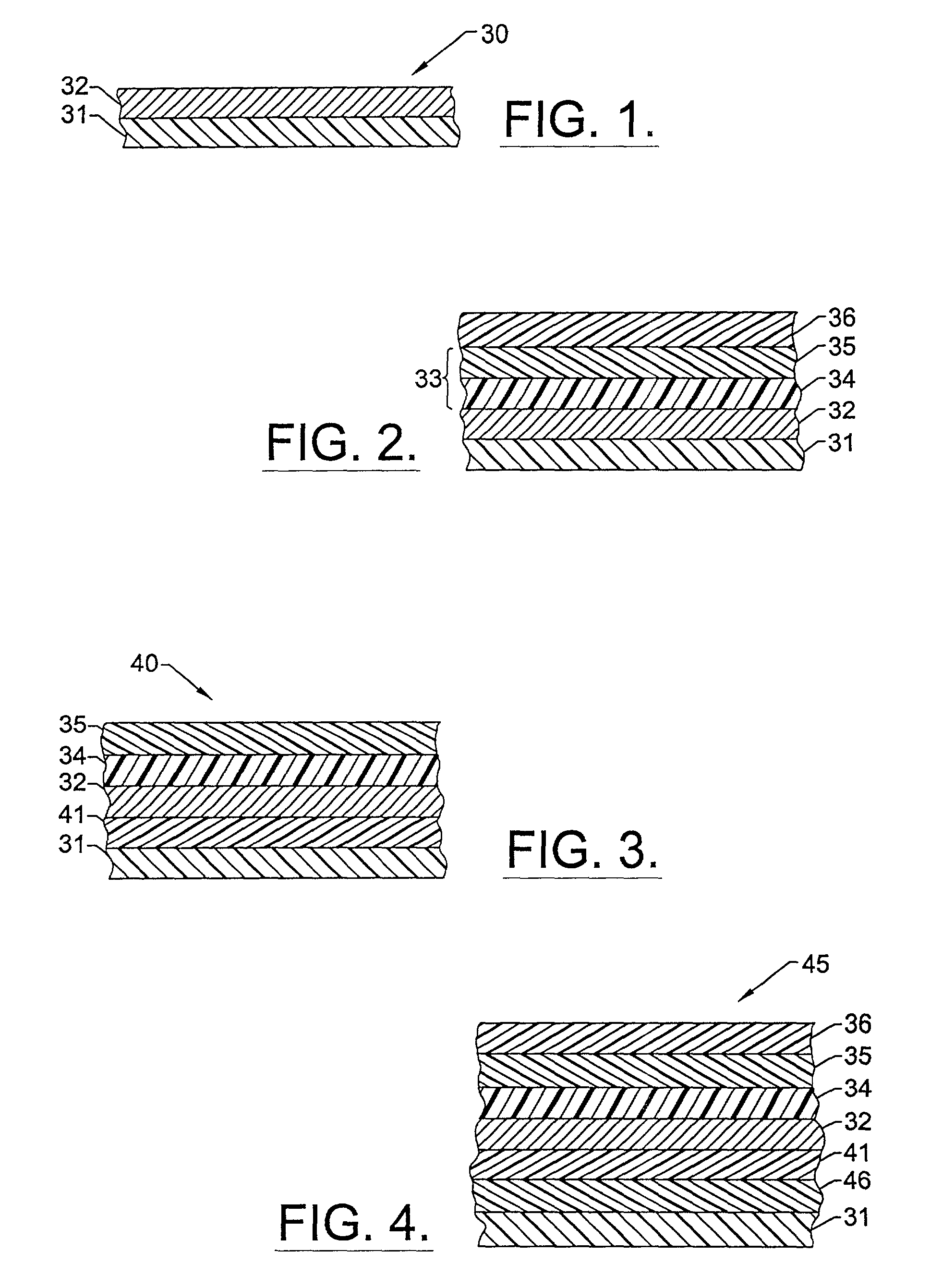

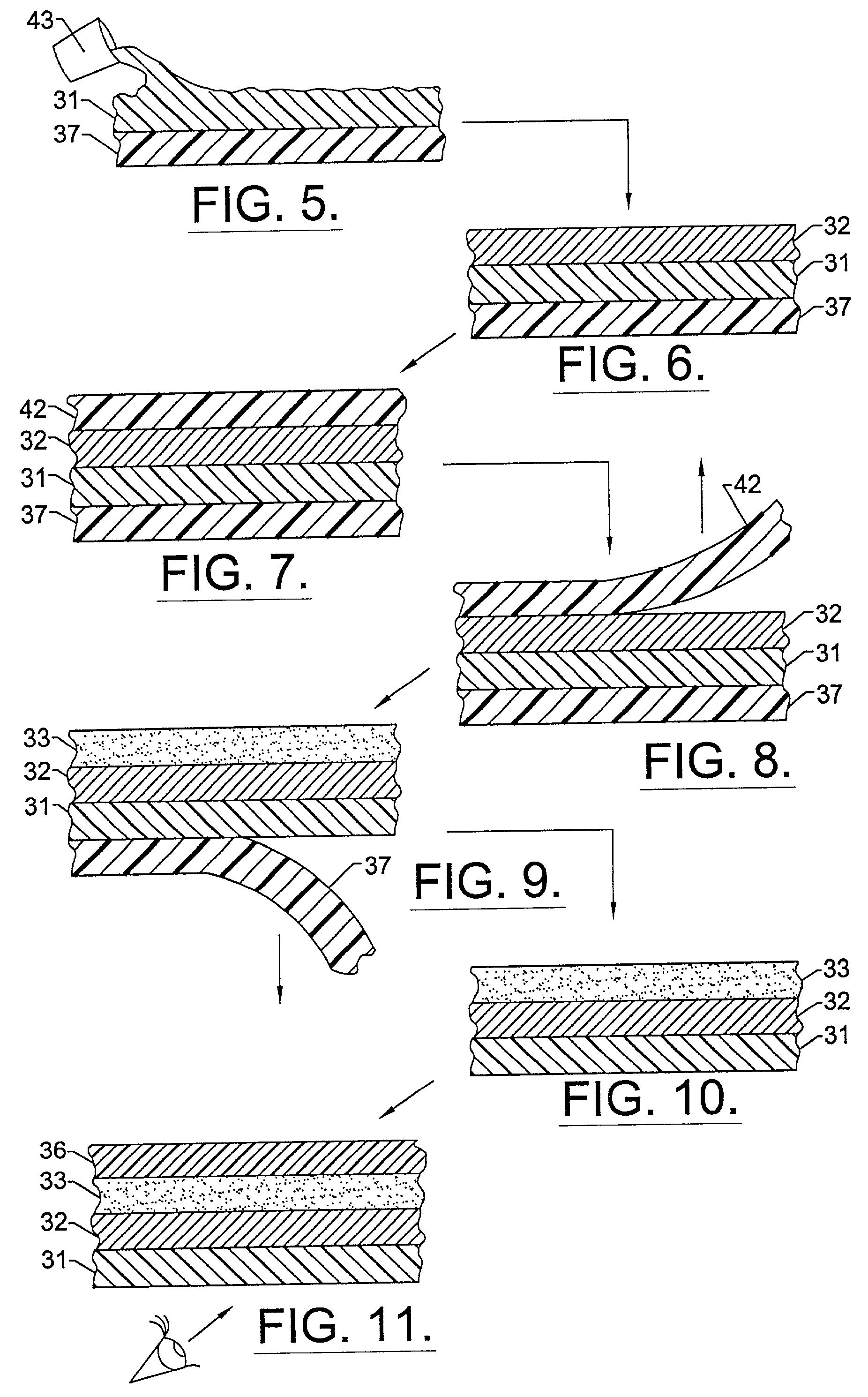

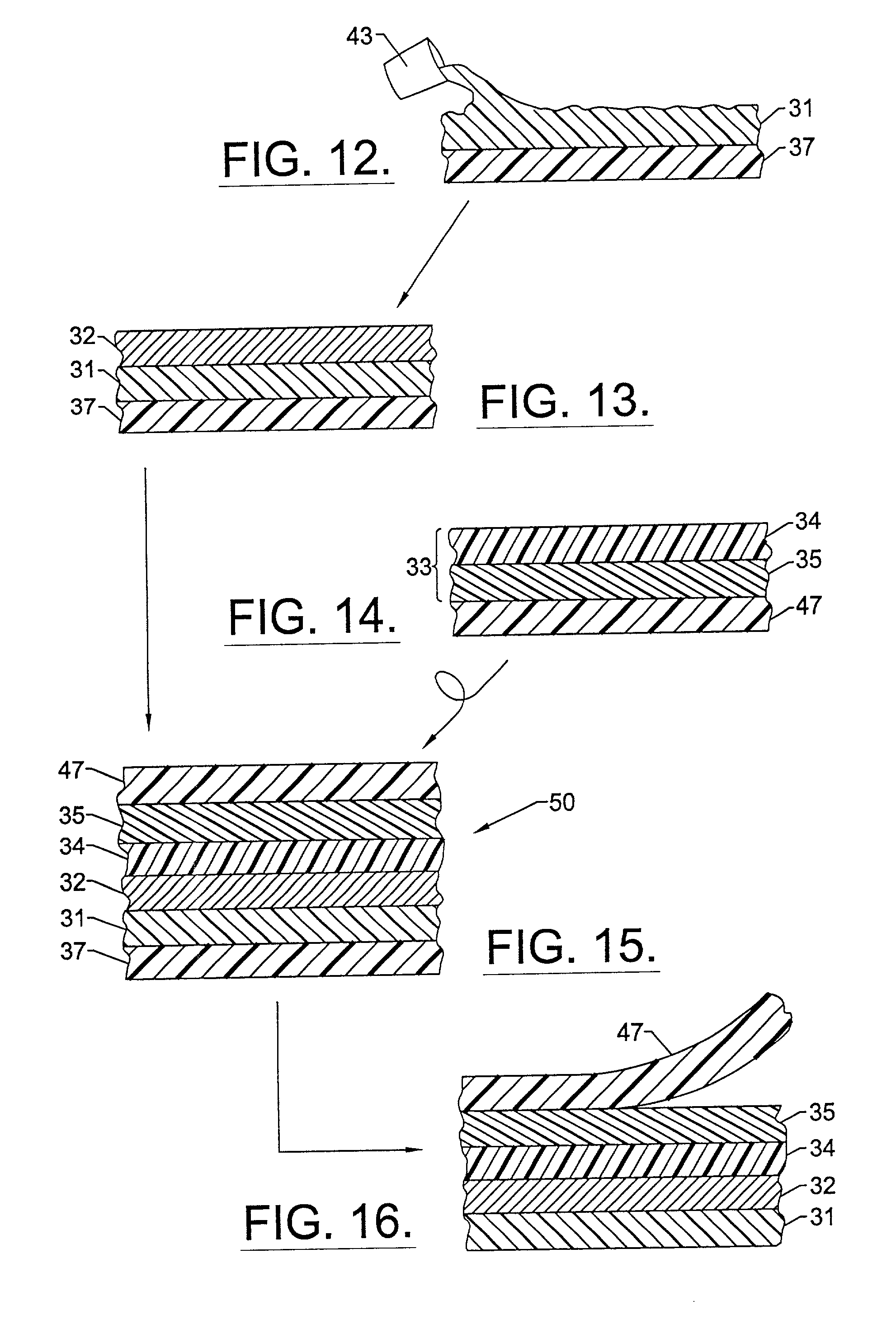

[0075] FIGS. 5-11 illustrate a method of making the invention. Where possible, the respective layers will carry the same reference numerals as in the previous drawings. Accordingly, FIG. 5 shows that in a first step, the PVDF-acrylic composition is cast onto the layer 31 from an appropriate casting source schematically illustrated at 43, onto a polyester substrate 37. Suitable casting methods include a knife-over roll coating process, a reverse roll coating process, or preferably a slot die coating process. The discontinuous layer of indium islands 32 is then added to the PVDF-acrylic layer 31 resulting in the structure illustrated in FIG. 6. In the next step, a second polyester layer 42 is added for the purpose of press polishing the indium layer 32 in the manner described previously. FIG. 8 illustrates that this polyester layer 42 is then removed leaving the smooth surface of the indium layer 32 behind.

[0076] FIG. 9 illustrates the next two steps in which the original polyester la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com