Chemistry for chemical vapor deposition of titanium containing films

a technology of titanium containing film and chemical vapor deposition, which is applied in the direction of chemical vapor deposition coating, coating, coating process of metallic materials, etc., can solve the problems of high deposition temperature, inability to fully perform the function of thin films, and increased likelihood of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the interest of clarity, not all features of an actual implementation into an integrated circuit process are described in this specification. This illustration is restricted to those aspects of an integrated circuit process involving the deposition of thin films. Conventional details of integrated circuit processes, such as mask generation, resist casting, resist development, etching, doping, cleaning, implantation and annealing are not presented as such details are well known in the art of integrated circuit manufacture.

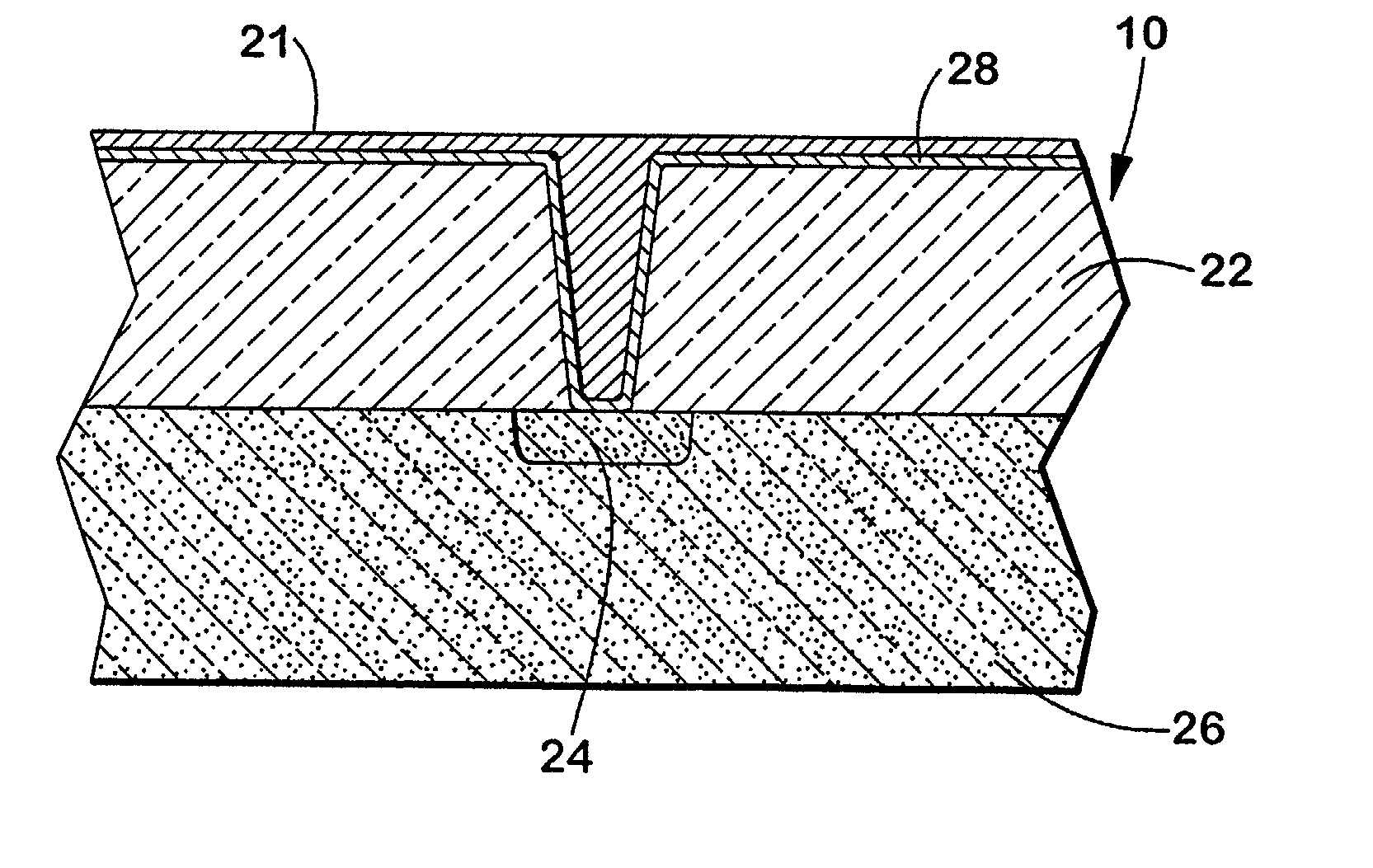

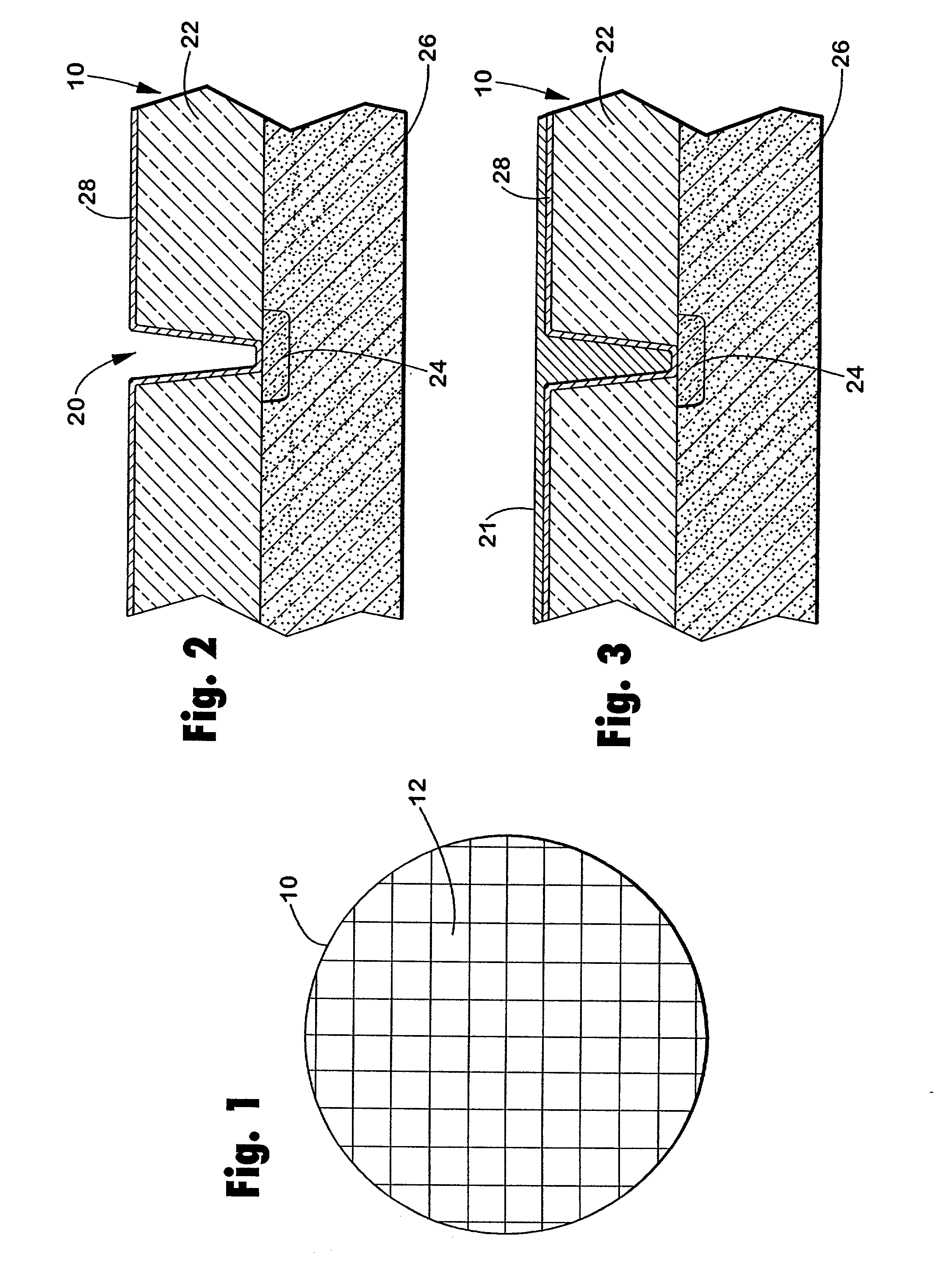

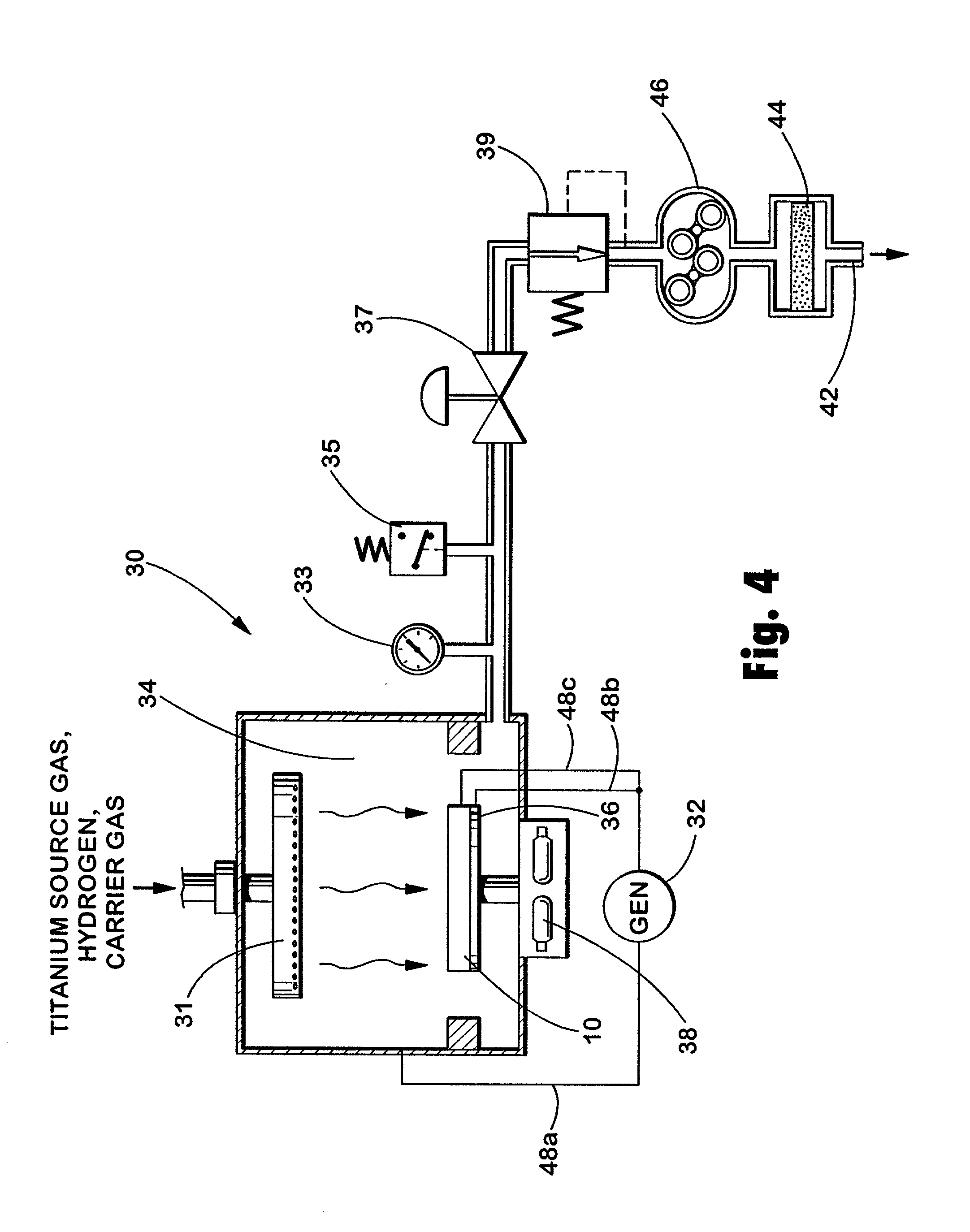

[0032] Turning now to the drawings, a typical semiconductor wafer is illustrated in FIG. 1 and designated by a reference numeral 10. The wafer 10 includes a number of different regions, known as die regions 12. Each die region 12 may include an integrated circuit containing various features and fabricated using various materials and processes. For the purposes of this discussion, one of the die regions 12 will be discussed. The die region 12 includes a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com