Implant with bioactive particles stuck and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

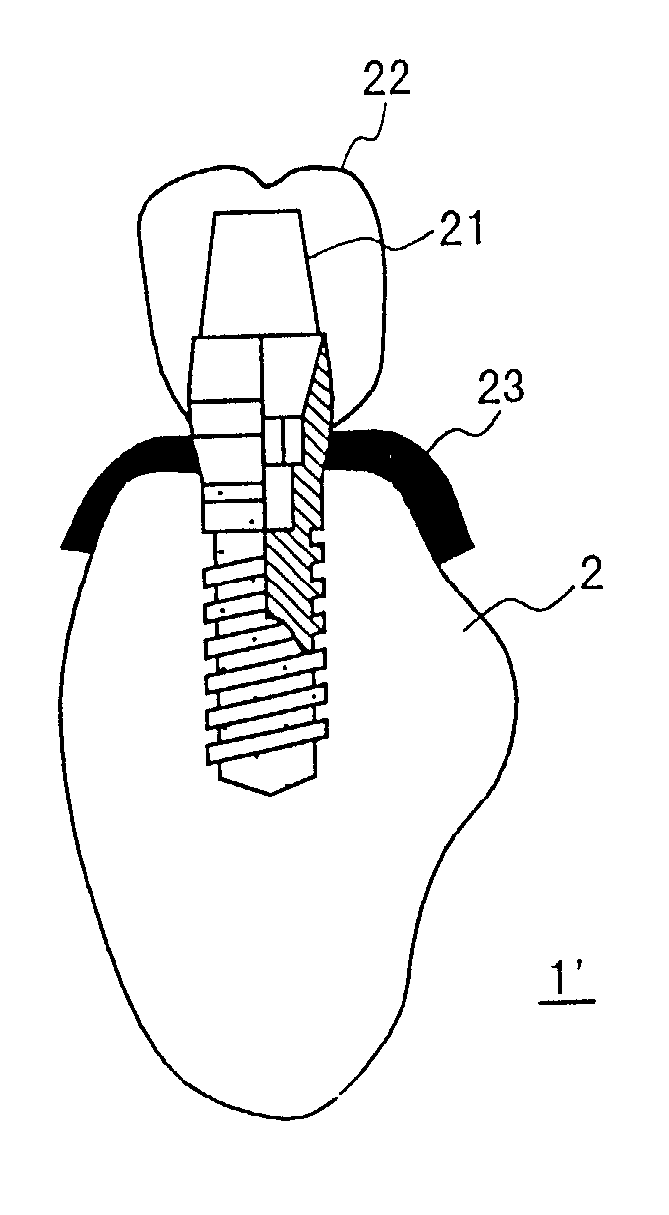

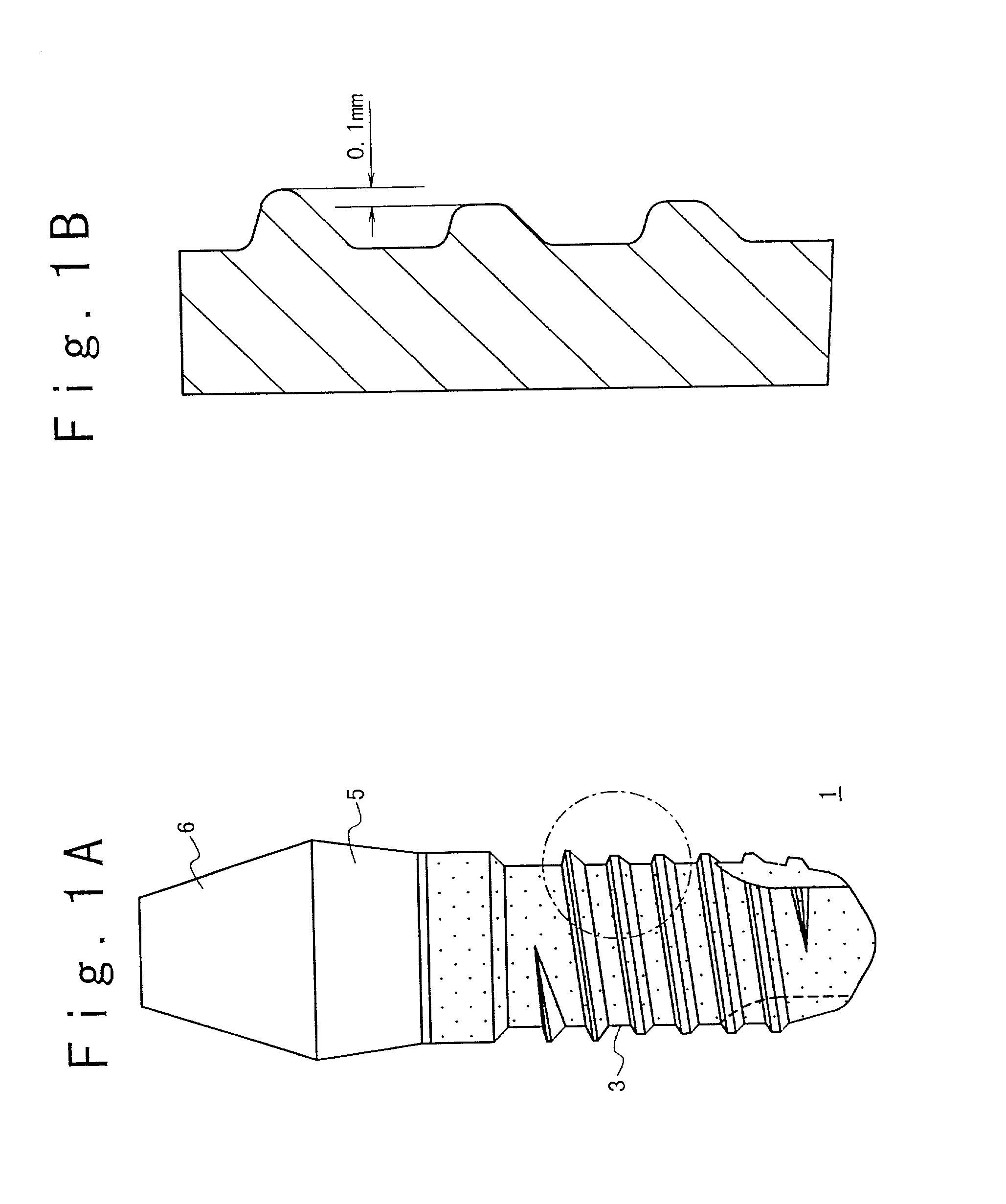

[0053] FIG. 1A shows the structure of a dentistry implant according to the present invention. Referring to FIG. 1A, a dentistry implant 1 is formed of material having bio-compatibility such as titanium or titanium alloy. The dentistry implant 1 is composed of an embedded section 3 embedded in jawbone 2, a gingiva penetrating section 5 to be located in gingiva, and a crowned section 6 which is located on the gingiva penetrating section 5. A thread is formed on the surface of the embedded section 3. As shown in FIG. 1B, the thread of an upper portion corresponding to a cortical bone section has a triangular cross section and the thread of a lower portion corresponding to a bone marrow section has a trapezoidal cross section. Therefore, the thread of the upper portion is higher than the thread of the lower portion by a predetermined height, e.g., 0.1 mm. This height difference makes insertion of the implant easy. In this example, the heights of the thread portions are different in a st...

fourth embodiment

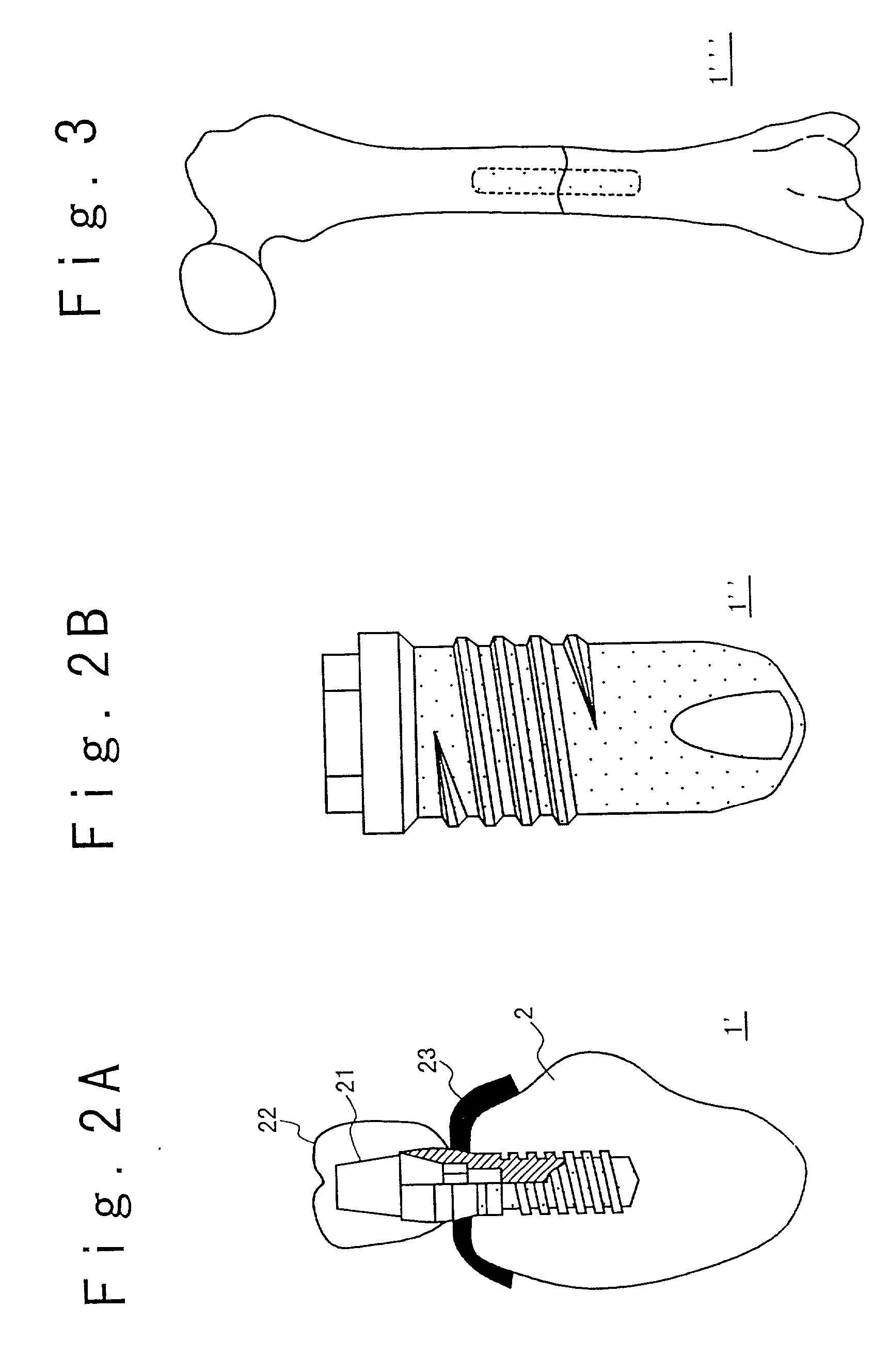

[0056] FIG. 3 shows a use example of an implant 1'" according to the present invention. In this embodiment, the implant 1'" is embedded in femur sections to couple femur sections.

[0057] In the implants shown in FIGS. 1A, 2A and 2B, the whole surface of the embedded section 3 of the implant main body member as an original implant is made rough and bioactive particles having osteo-conduction are stuck on the whole surface of the embedded section 3. However, the rough surface portion with stuck particles may be formed only below the upper portion of the thread portion.

[0058] Referring to FIG. 11, a method of manufacturing of the implant 1 in the first embodiment will be described below.

[0059] In a step S2, the gingiva penetrating section 5 and the crowned section 6 of the main body member of titanium as an original implant 1 are masked not to be hit with grinding particles. Then, while the original implant is rotated, a primary sand blasting process is performed to the surface of the e...

example 1

[0079] Only the secondary sand blasting process is performed to the embedded section 3 of the blade-shaped original implant 1 of titanium with the blasting pressure of 0.7 Pa using 45S5 glass particles with an average grain diameter of 0.1 mm. By this, as shown in FIG. 12, the blade-shaped implant formed of titanium is obtained to have an initial osteo-conduction, to have suitable surface roughness for bone, and contain a little amount of 45S5 glass 7. In this case, the gingiva penetrating section 5 and the crowned section 6 are masked such that the blasting particles do not hit. However, the secondary sand blasting process may be performed to the gingiva penetrating section 5 and the crowned section 6. In this example, the original implant is not rotated. However, it may be rotated during the sand blasting process as described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Compatibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com