Evaporative desorption soil treatment apparatus and process

a technology of evaporative desorption and treatment apparatus, which is applied in the direction of drying machines, lighting and heating apparatus, furnaces, etc., can solve the problems of unburned hydrocarbons in the process exhaust gas, potential for spillage, and potential for leakage, and achieve the effect of reducing the risk of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

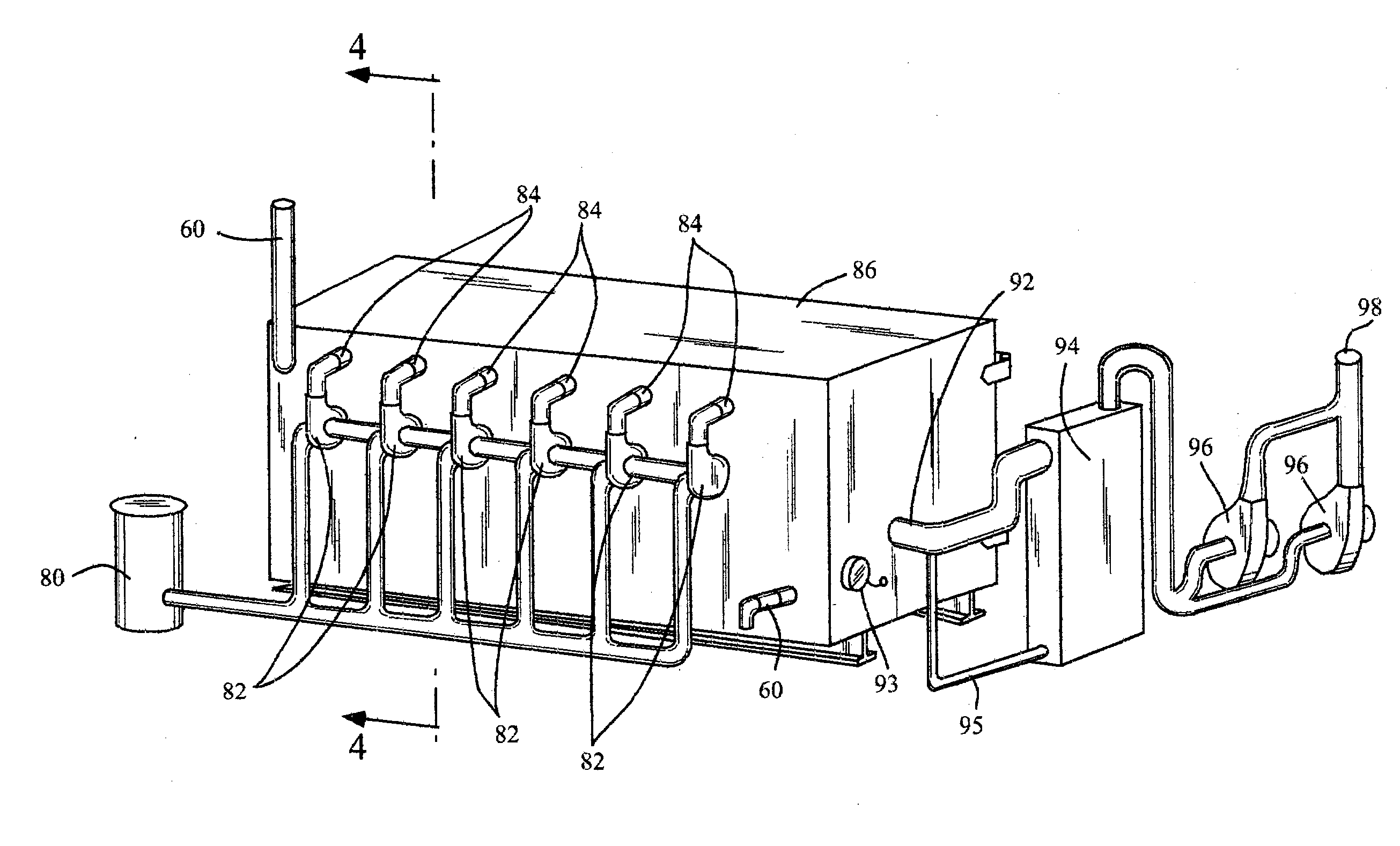

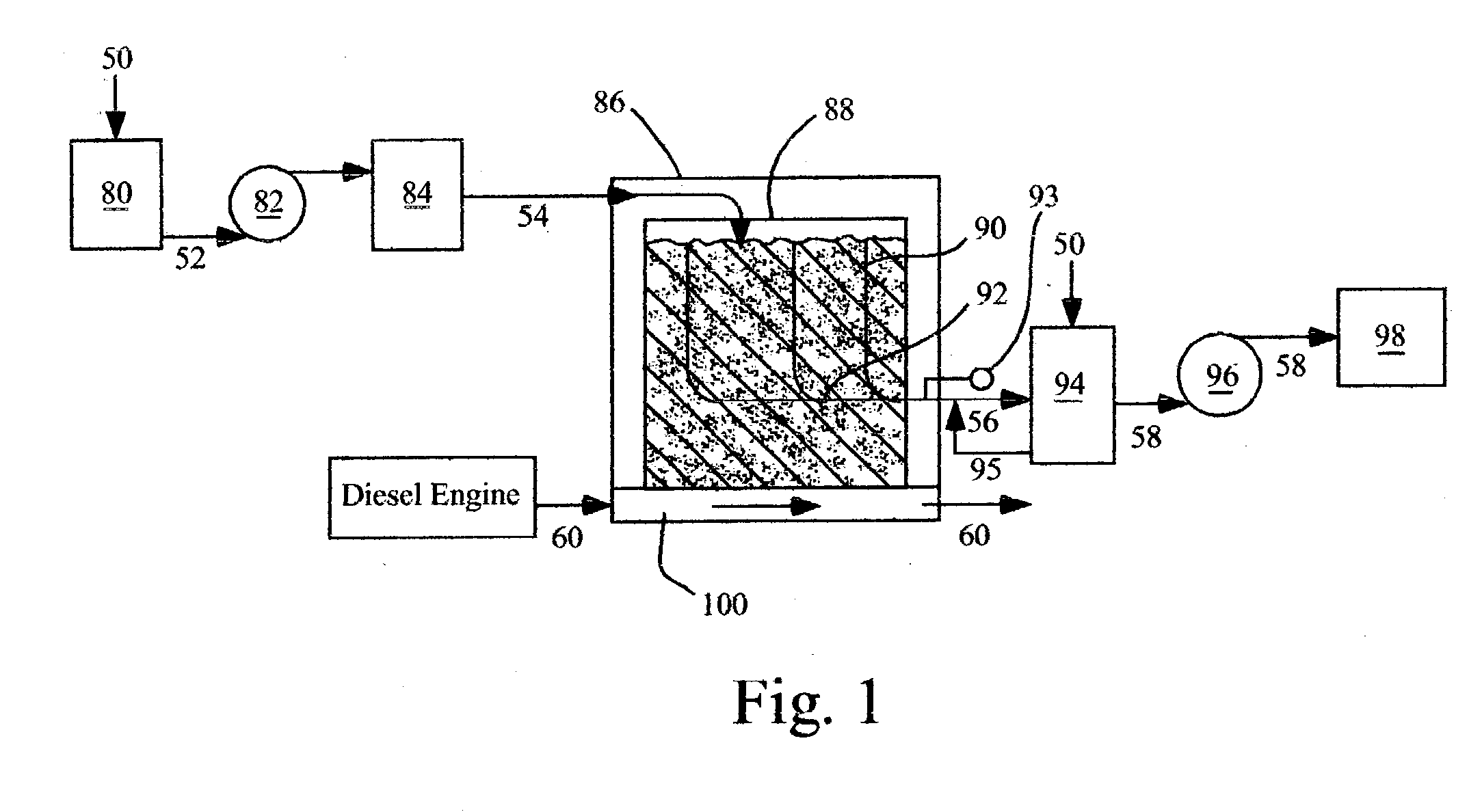

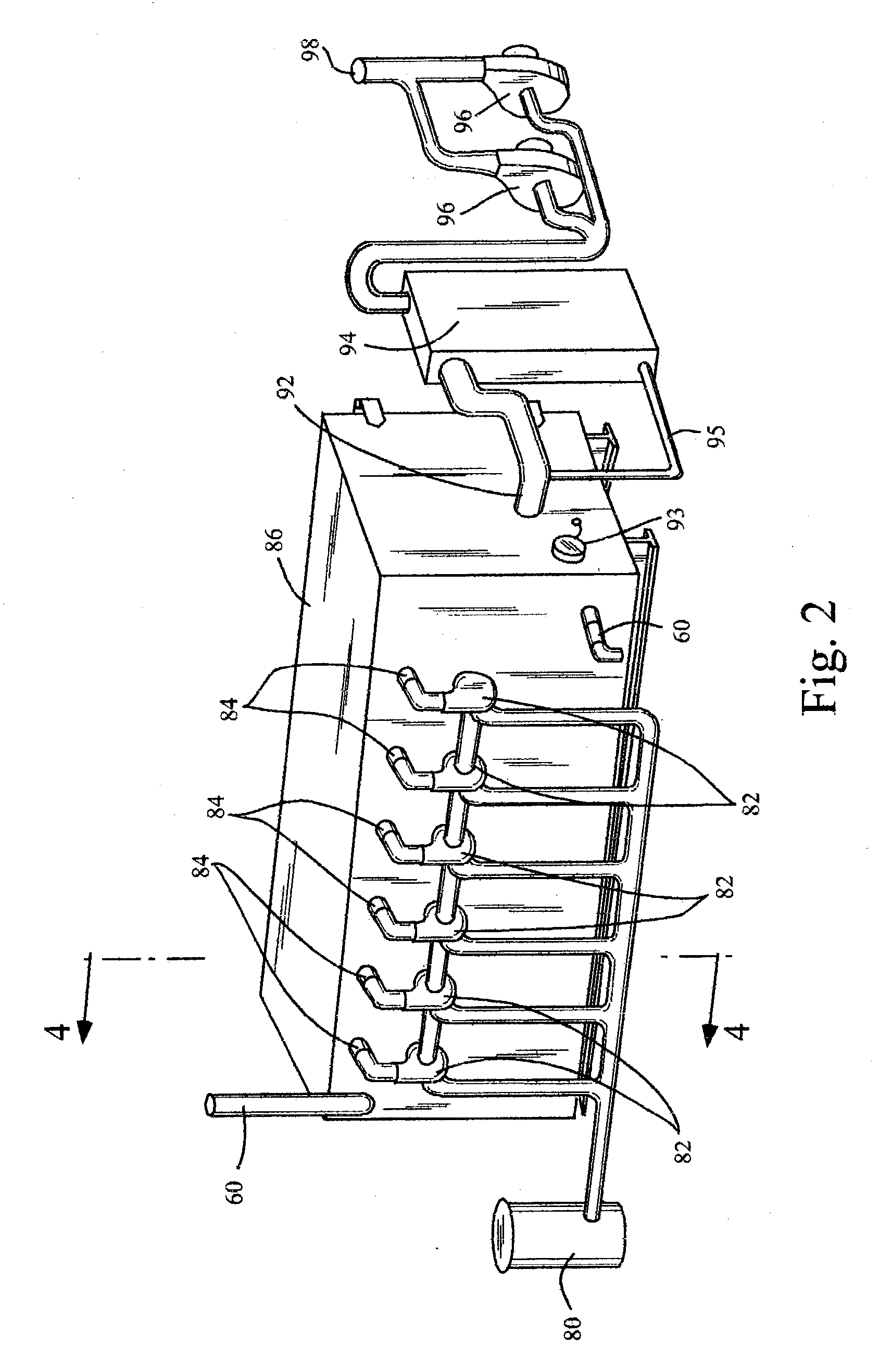

[0070] FIGS. 1 through 7 show the preferred embodiment of the evaporative desorption soil treatment process apparatus. FIG. 1 shows the treatment process method and FIGS. 2 through 7 show the arrangement of the apparatus. Treatment is done in a metal treatment chamber with internal thermal insulation as shown in FIG. 4. This figure shows the contaminated soil (90) that was dug from the contamination site, located in the open-top thermal conductive treatment vessel (88), which in turn is located in the treatment chamber (86). The soil is generally a mixture of soil and rocks. The contaminates in the soil and their concentrations may vary depending on the location they are dug from at the contaminated site.

[0071] The treatment vessel is a removable, sometimes called a roll-off, hopper modified to contain the gas exit pathway (92). FIG. 5 shows this pathway (92) is a slotted or perforated piping array located near the centerline of the treatment vessel at an elevation from the floor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com