Clamp circuit

a technology of clamping circuit and clamping plate, which is applied in the direction of pulse manipulation, pulse technique, instruments, etc., can solve the problems of lowering the response speed, raising the production cost of the clamping circuit, and the inability to employ the low withstand voltage device process,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

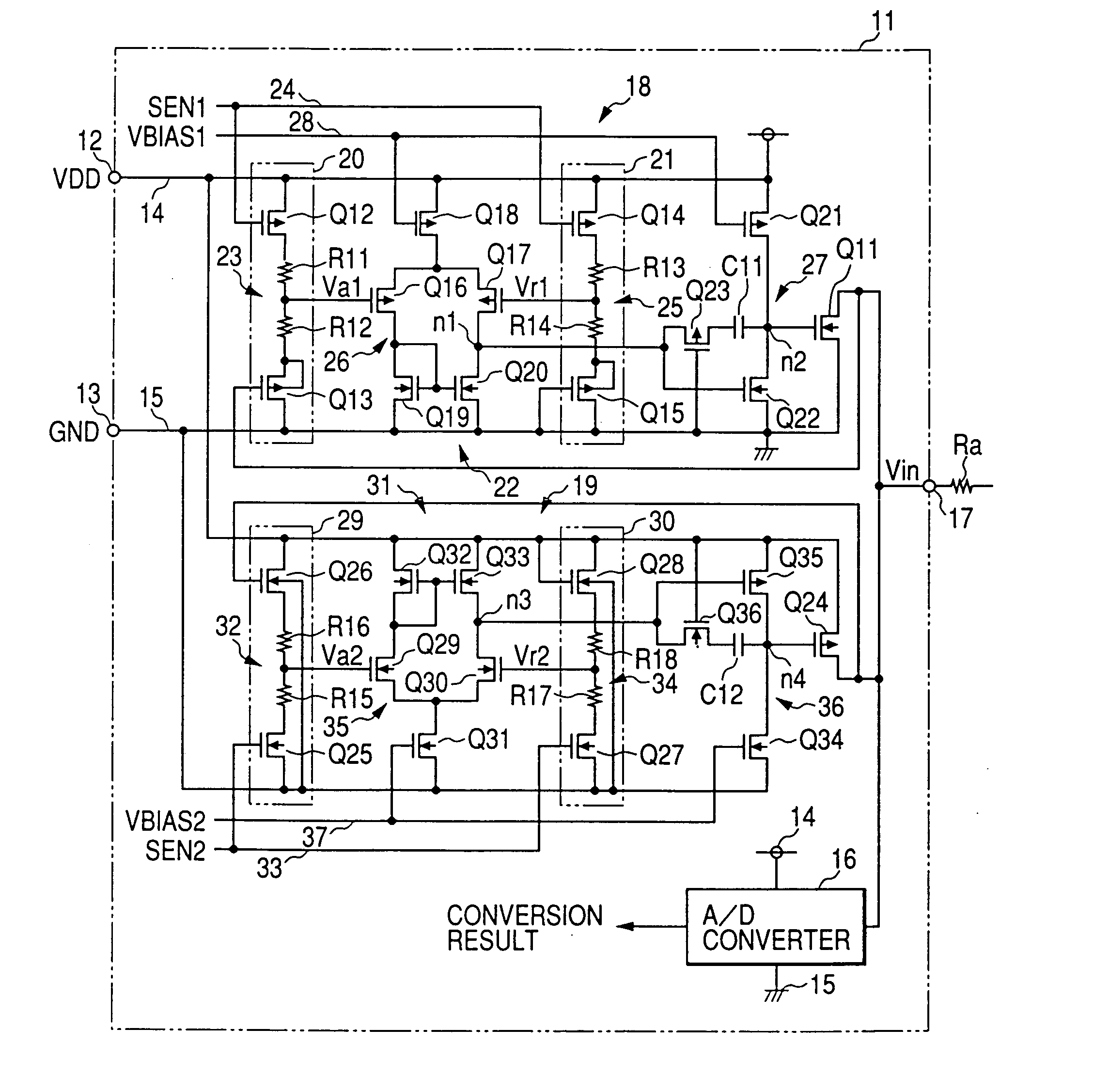

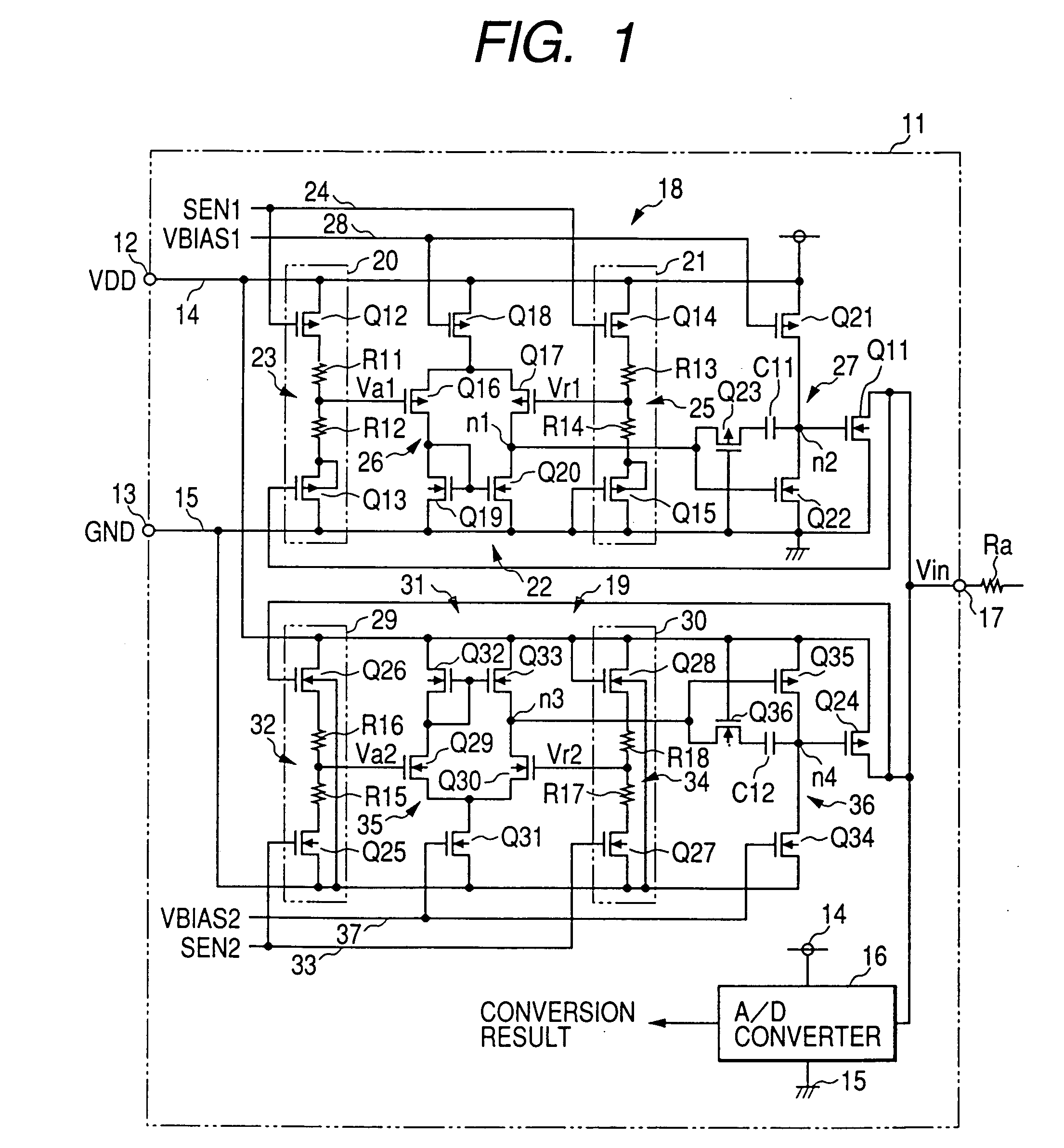

[0024] A preferred embodiment in accordance with the present invention are disclosed in detail, referring to FIG. 1 which shows a semiconductor IC for preventing a positive and negative overvoltage which might be caused by the voltages inputted into a semiconductor IC 11 mounted on a not-shown control substrate in an electronic control unit (ECU).

[0025] There is also mounted on the not-shown control substrate a not-shown power supply IC which allows the IC 11 to operate under V.sub.DD supplied through supply terminals 12 and 13 from the not-shown supply IC. Here, An accuracy of V.sub.DD is, e.g., 5 V.+-.5%. The supply terminals 12 and 13 are connected inside the IC 11 with a higher voltage supply line 14 and lower voltage supply line 15, repectively.

[0026] Althroug the IC 11 manufactured by the CMOS process includes not-shown various analog and digital circuits, only an A / D converter 16 is shown in FIG. 1. The higher voltage is e.g., 5.5 V and the lower voltage is e.g., minus 0.5 V,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com