High tetragonality barium titanate-based compositions and methods of forming the same

a barium titanate and composition technology, applied in the field of high tetragonality barium titanatebased compositions and methods of forming the same, can solve the problem of sacrificing the dielectric constant of mlccs formed using small barium titanate-based particles, and achieve high tetragonality, high tetragonality, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0053] This example shows the effect of strontium concentration on the tetragonality of barium titanate compositions.

[0054] Barium titanate particle samples were produced in three different hydrothermal processes. In the first process, the barium source had a strontium concentration of 439 ppm. In the second process, the barium source had a strontium concentration of 387 ppm. In the third process, the barium source had a strontium concentration of 222 ppm. The strontium concentration was measured using an inductively coupled plasma (ICP) spectroscopy technique.

[0055] The average particle size for each sample was about 0.15 micron. The A / B ratios of the samples were not adjusted. Each sample was heat treated at 1000.degree. C. The average particle size for each sample was about 0.40 micron after heat treatment.

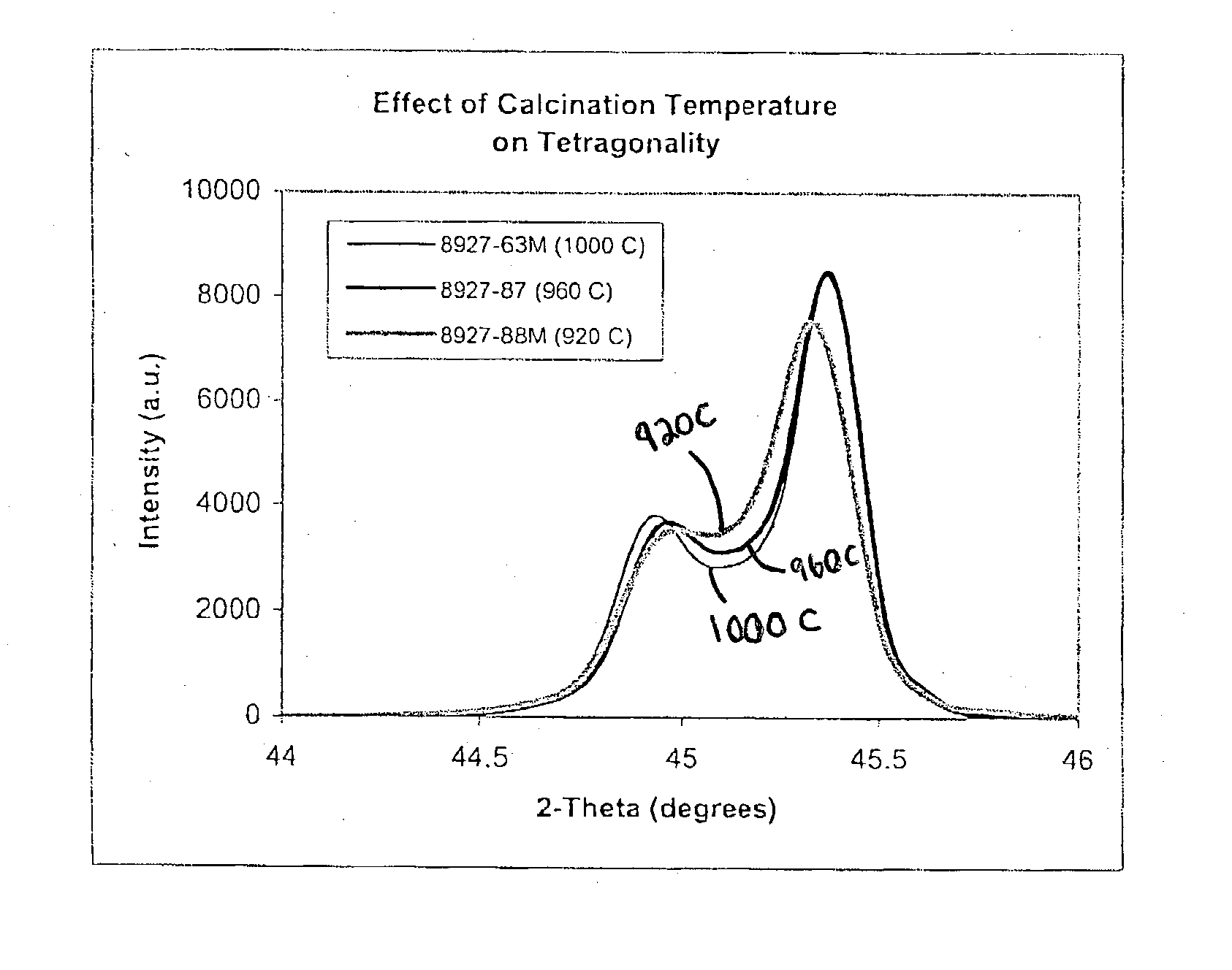

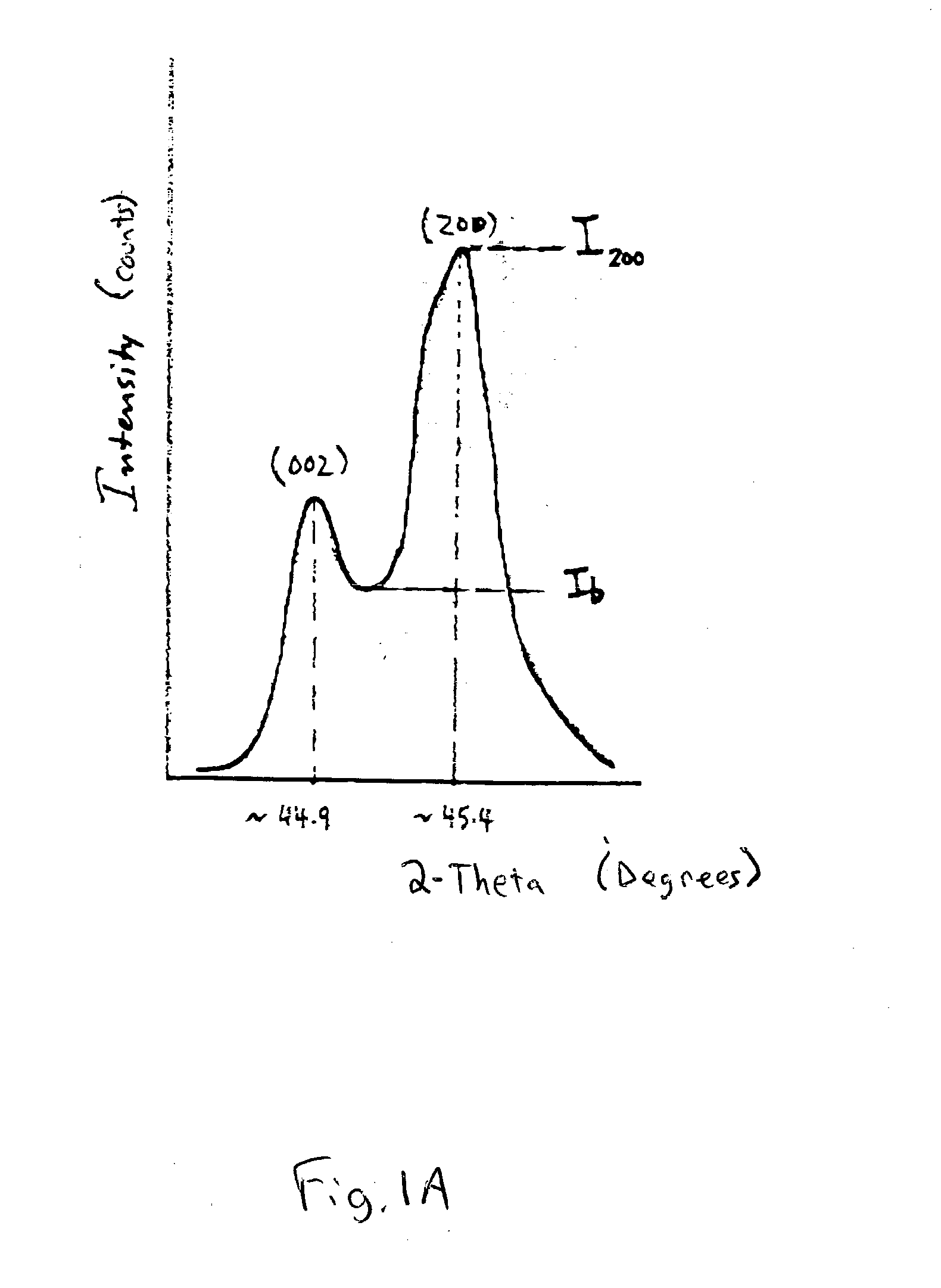

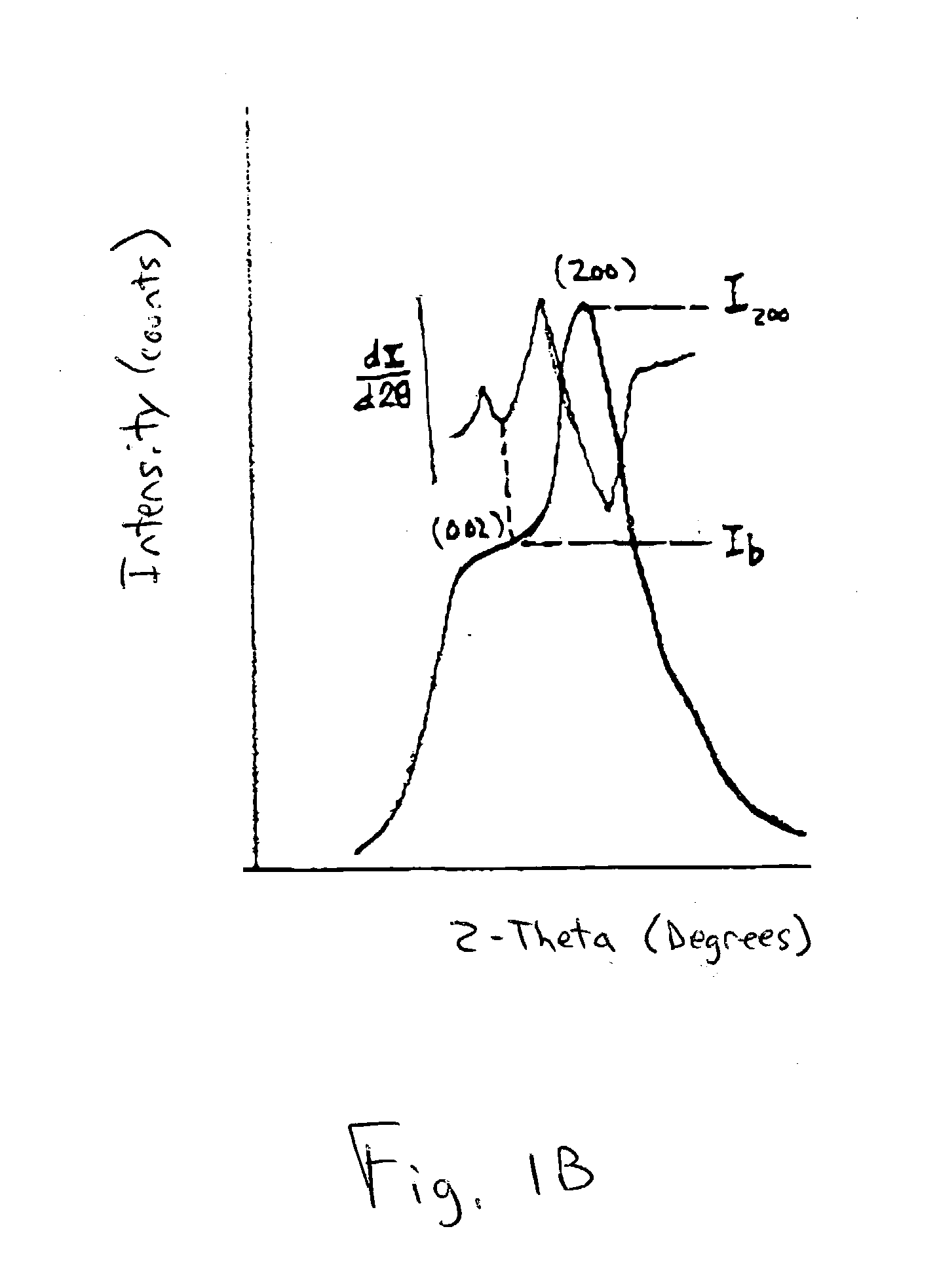

[0056] Each sample was analyzed using an x-ray powder diffraction technique to determine the tetragonality. The diffraction technique used a copper target at a voltage of 40 kV...

example 3

[0059] This example shows the effect of A / B ratio on particle size growth during heat treatment of barium titanate compositions.

[0060] Barium titanate particles were produced in a hydrothermal process. The barium source had a strontium concentration of 50 ppm. The average particle size of the barium titanate was about 0.060 micron. Three samples were produced by adjusting the A / B ratio to different values. The first sample was washed with deionized water to reduce the A / B ratio to 0.983. The second sample was washed with deionized water to reduce the A / B ratio to 0.995. The third sample was processed to coat barium carbonate on particle surfaces (using a precipitation technique involving adding barium hydroxide and ammonium carbonate to a slurry of the particles) to increase the A / B ratio to 1.013. The A / B ratio of a fourth sample was not adjusted from 1.000.

[0061] The samples were heat treated at 1000.degree. C. The average particle size of each sample was measured. The sample havi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com