Hydrophilic material and process for producing the same

a technology of hydrophilic materials and hydrophilic polymers, which is applied in the field of polymer materials, can solve the problems that the combination of hydrophilic polymers, such as polyvinylpyrrolidone, alone is not significantly effective in controlling the activation of blood platelets, and achieves the effect of eliminating the defect of conventional materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

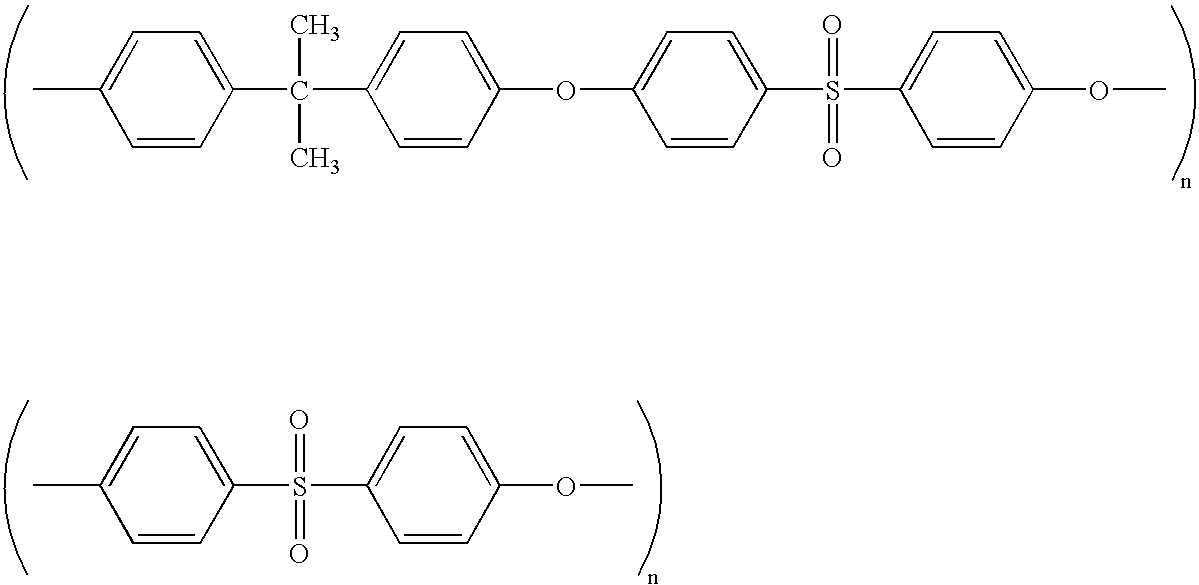

Method used

Image

Examples

example 2

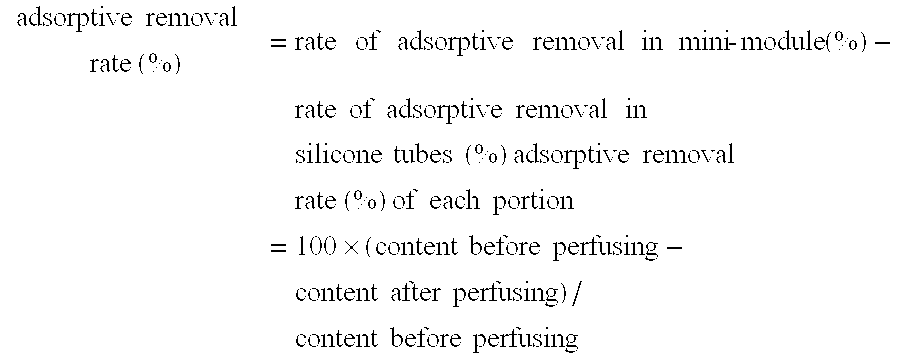

[0056] A hollow fiber membranes produced by the same procedure as in Example 1 was put in a 1 wt % polyethyleneimine (Aldrich reagent, molecular weight 600) solution and irradiated with gamma ray. The gamma ray absorbed dose was 29 kGy. The number of blood platelets adsorbed by the hollow fiber membrane is shown in Table 1.

example 3

[0057] A hollow fiber membranes produced by the same procedure as in Example 1 was put in a 1 wt % diethylaminoethyl dextrane (supplied by Sigma, molecular weight 500,000) solution and irradiated with gamma ray. The gamma ray absorbed dose was 29 kGy. The number of blood platelets adsorbed by the hollow fiber membrane is shown in Table 1.

example 4

[0065] Polysulfone film 1 was put in a 0.1 wt % polyethyleneimine (supplied by Sigma, molecular weight 750,000) solution and irradiated with gamma ray. The gamma ray absorbed dose was 29 kGy. The film was in an insoluble state. The film was then rinsed with purified water, stirred in 80.degree. C. purified water for 60 min, and after replacing the purified water, stirred at 80.degree. C. for another 60 min. The purified water was replaced again and stirring was performed at 80.degree. C. for another 60 min to ensure complete removal of adsorbed polyethyleneimide. The number of blood platelets adsorbed by the film is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com