Device for metering a urea soulution

a technology of urea solution and metering device, which is applied in the direction of machines/engines, separation processes, instruments, etc., can solve the problem of relatively unproblematic measurement of state variables, and achieve the effect of accurate and selective determination of urea concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

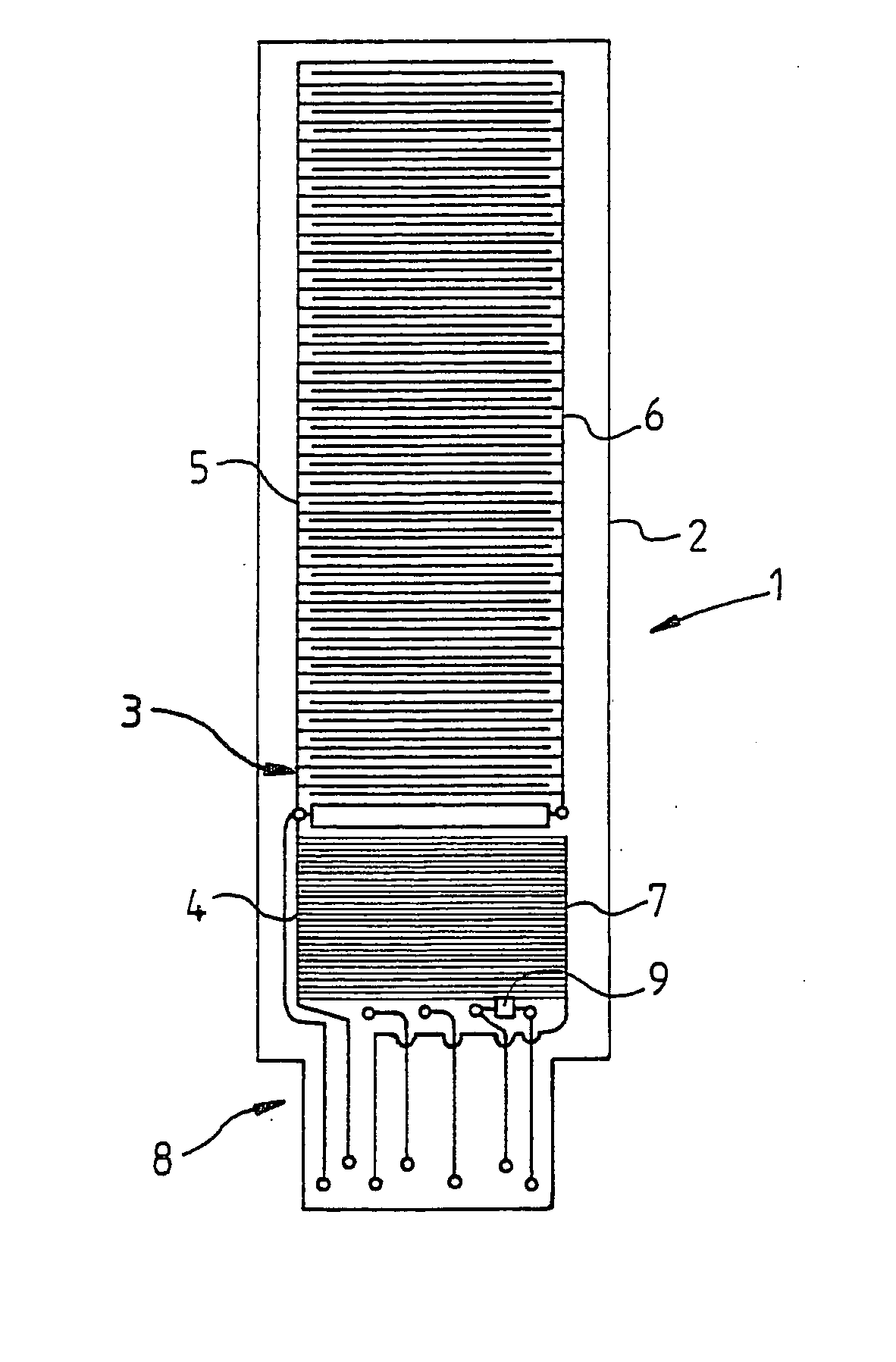

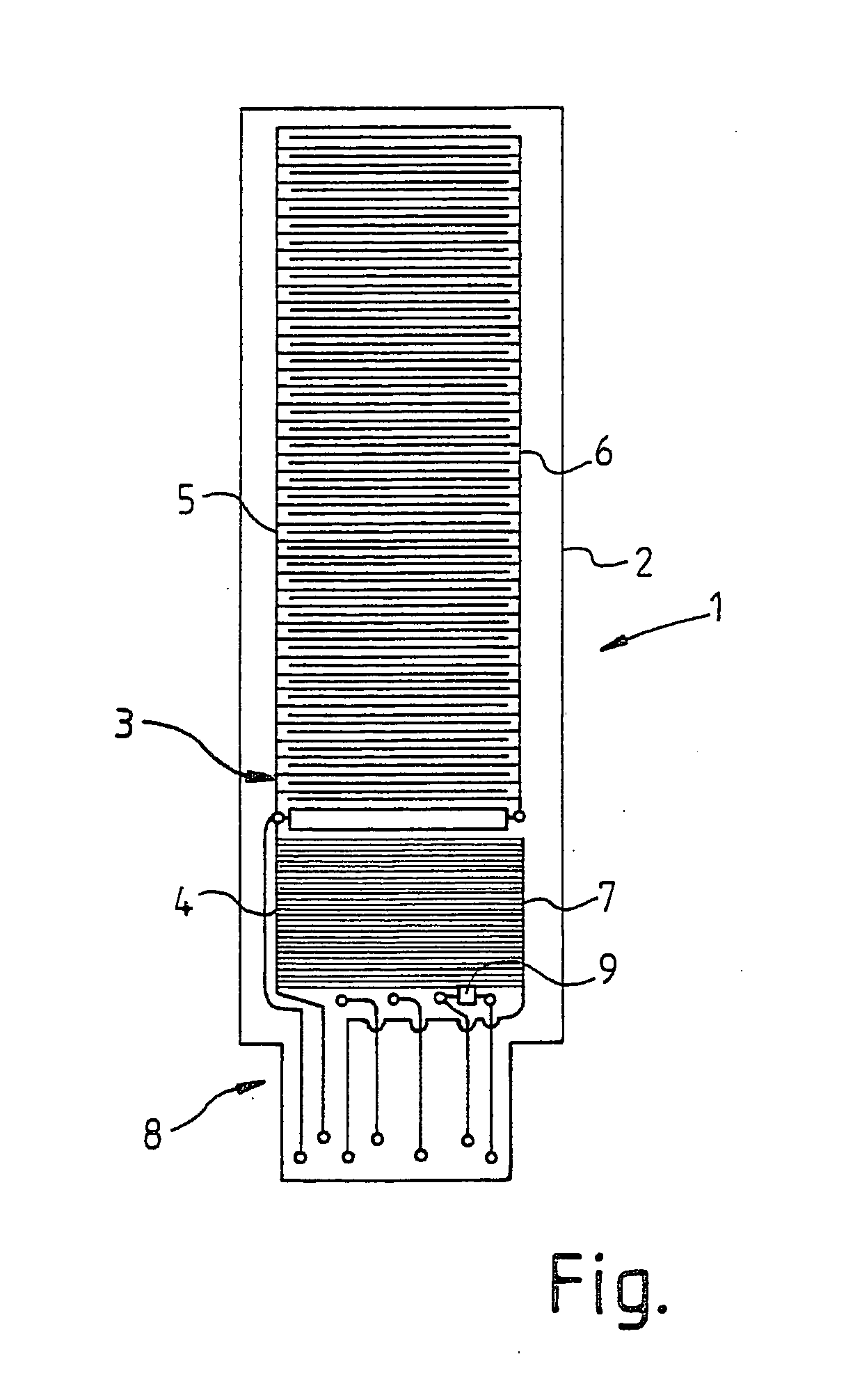

[0022] Sensor unit 1 is mounted on a sensor plate 2. A comb-shaped electrode 3 is divided into two areas 4, 5. Individual teeth of the comb structure are spaced farther apart in upper area 5 than in lower area 4. In upper area 5, another electrode 6 engages with a corresponding comb structure. The two electrodes 5 and 6 extend over a large area of sensor plate 2 and constitute a filling level sensor. A third electrode 7 is situated opposite lower area 4 of electrode 3. The comb structure of electrode 7 corresponds to the finer comb structure of lower area 4 of electrode 3, i.e., the teeth are not as far apart.

[0023] Together with lower area 4 of electrode 3, electrode 7 forms a measuring sensor according to an exemplary embodiment of the present invention for measuring an electric state variable, e.g., the conductivity, the dielectric constant, etc.

[0024] Electric terminals 8 for electrodes 3, 6, 7 are provided in the lower area of sensor plate 2. These electric terminals 8 may be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| physical state | aaaaa | aaaaa |

| electric state | aaaaa | aaaaa |

| dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com