Binder systems derived from amorphous silica and bases

a technology of amorphous silica and binding system, which is applied in the direction of ceramic shaping apparatus, solid waste management, climate sustainability, etc., can solve the problem that organic binding system may be inflammabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

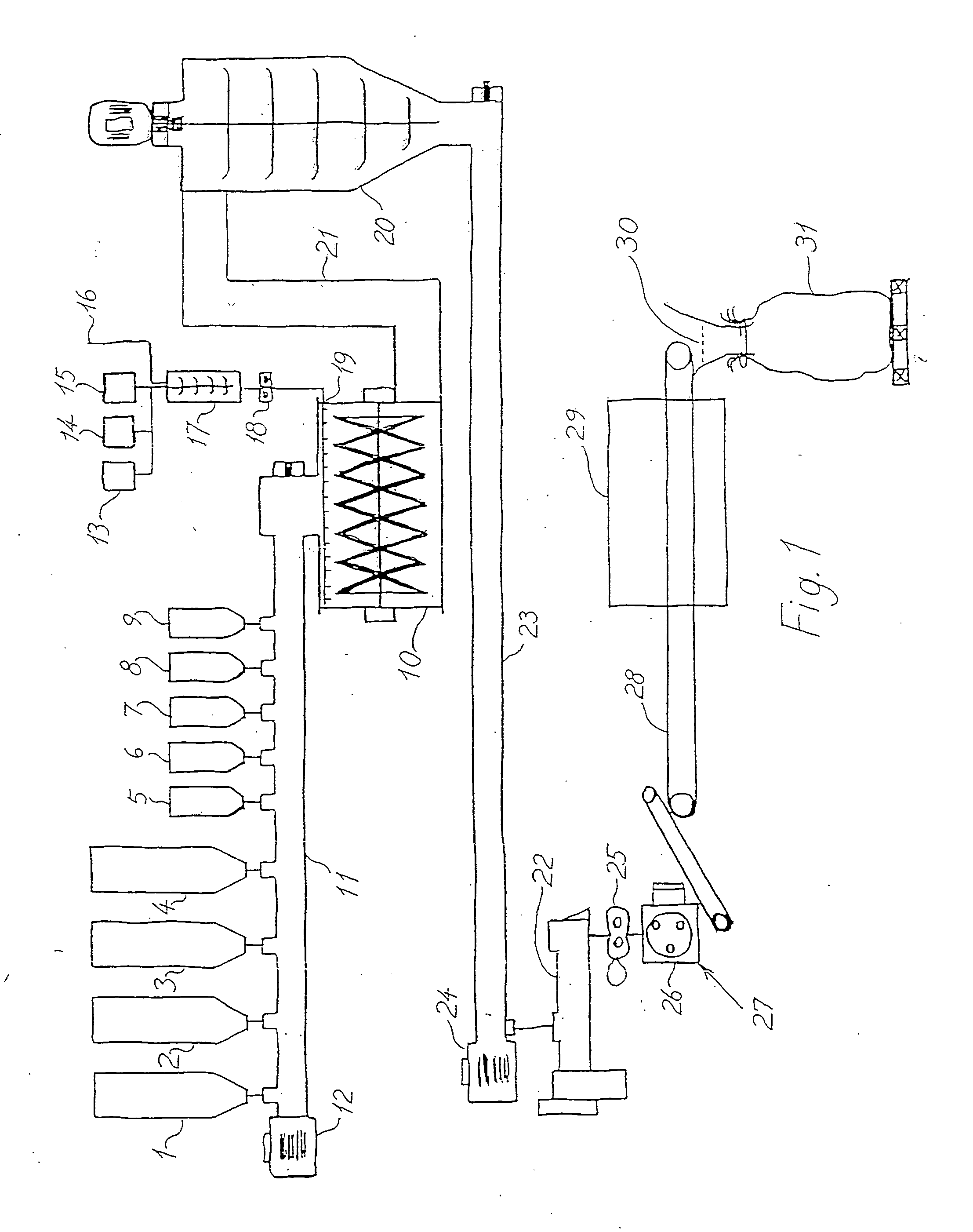

Image

Examples

examples

All values are in grams (g) unless otherwise specified. % is percent by weight unless otherwise stated.

Silica slurry was obtained from Elkem Materials, Norway (Elkem Microsilica® slurry). The concentration of the slurry was 50% silica by weight.

Potassium methyl siliconate as a 42% aqueous solution (Wacker BS-15) was obtained from Wacker Chemie GmbH, Germay.

Potassium hydroxide pellets were obtained from Bie & Bemtsen A / S, Denmark.

Sodium hydroxide pellets (Afløbsrens) were obtained from the grocery store.

Rockwool® Hulrumsfyid (mineral wool) and Glasuld® Hulrumsfyld (glass wool) from Ledreborg Tømmerhandel, Roskilde, Denmark.

Loose silica was obtained from Elkem Materials, Norway (Elkem Microsilica®).

Densified silica was obtained from Elkem Materials, Norway.

Sand-lime mortar was obtained from Dansk SystemMørtel A / S, Denmark.

Soda lye (27%) and soda water glass was obtained from Borup Kemi, Denmark.

Basic, rapid, ultra and white cements were obtained from Aalborg Portl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com