Low friction planarizing/polishing pads and use thereof

a technology of low friction and planarizing, applied in the field of pads, can solve the problems of reducing the removal rate, reducing the efficiency of the process, so as to reduce the removal rate and reduce the friction of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

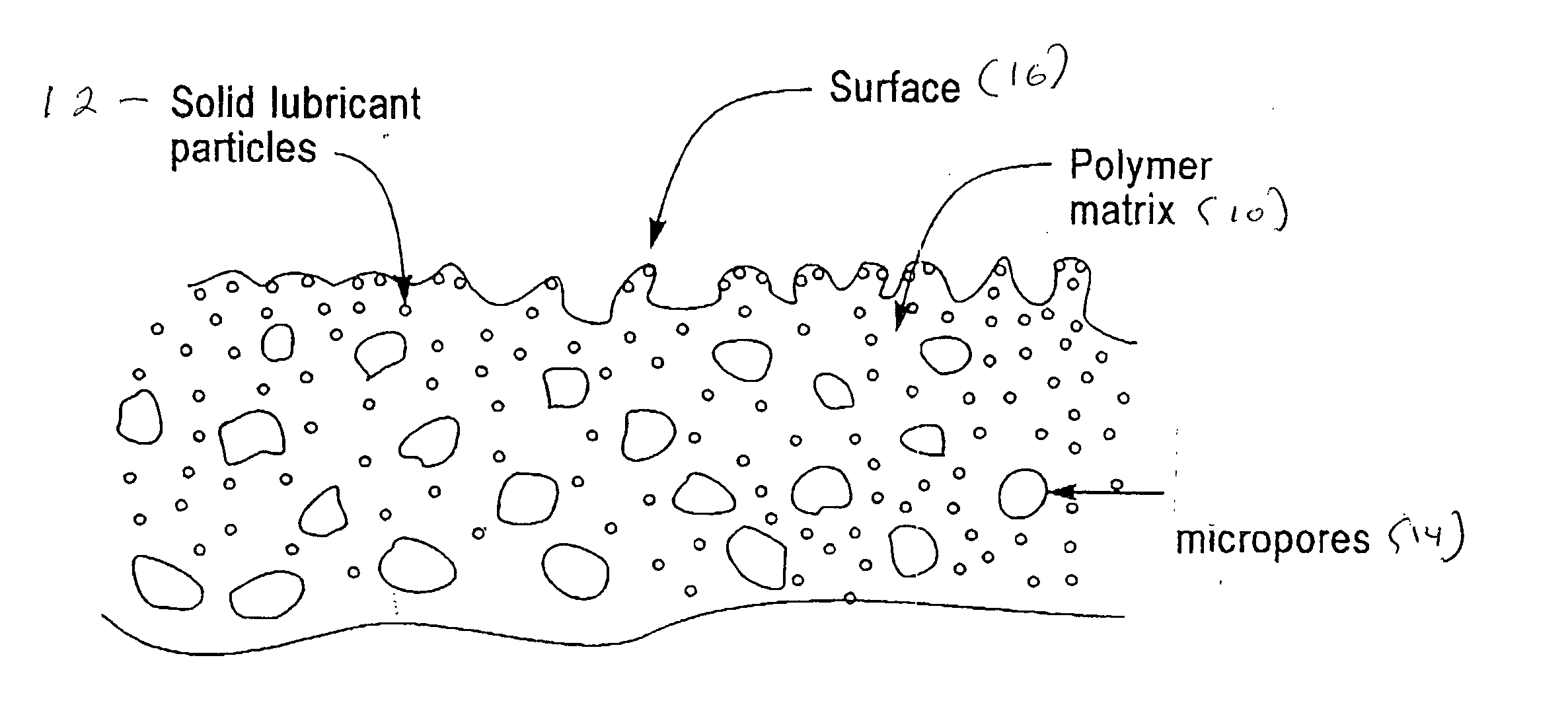

[0047] A porous polyurethane pad is provided according to the method in U.S. Pat. No. 5,900,164 by mixing liquid urethane with a polyfunctional amine at a proper temperature in the ratio required by the desired amount of cross-linking. During the “low viscosity window” hollow elastic polymeric microspheres are blended with the polymers mixture and 2% by weight of PTFE solid lubricant particles of 0.2 micron average diameter available under the trade name of Pinnacle 9003 by Carroll Scientific Inc., are blended applying a high shear rate mixer. The solid lubricant particles can be added to the liquid urethane or the liquid urethane-polyfunctional amine mixture, or the liquid urethane-polyfunctional amine-microspheres mixture.

[0048] The mixture is transferred during the low viscosity window to a convention mold and permitted to gel. It is subsequently cured in an oven, cooled and cut to form polishing pads. FIG. 3 shows the cross-section of a planarizing pad according to the present ...

example 2

[0050] In producing a non-porous pad the process of Example 1 is followed except that the hollow microspheres are not added. Thus a liquid urethane is mixed with a polyfunctional amine at a proper temperature in a ratio required by the desired amount of cross-linking. During the “low viscosity window” 3% by weight of PTFE solid lubricant particles of 0.2 micron average diameter with the trade name of Pinnacle 9003 by Carroll Scientific Inc. are blended into the liquid polymer mix applying a high shear rate mixer. The lubricant particles can be added into the liquid urethane, or into the liquid urethane-polyfunctional amine mixture.

[0051] The mixture is transferred during the low viscosity window to a conventional mold and permitted to gel. It is subsequently cured in an oven, cooled and cut to form a polishing pad. Since this pad does not transport slurry well a surface texture providing macroscopic channels for slurry transport is mechanically produced on the surface of the pad be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com