Ceramic materials reinforced with single-wall carbon nanotubes as electrical conductors

a carbon nanotube and ceramic material technology, applied in the field of electricly conductive ceramics, can solve the problems of brittleness of nanocrystalline ceramics and best conductivity being only available in the center of extrusion, and achieve the effect of reducing processing tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

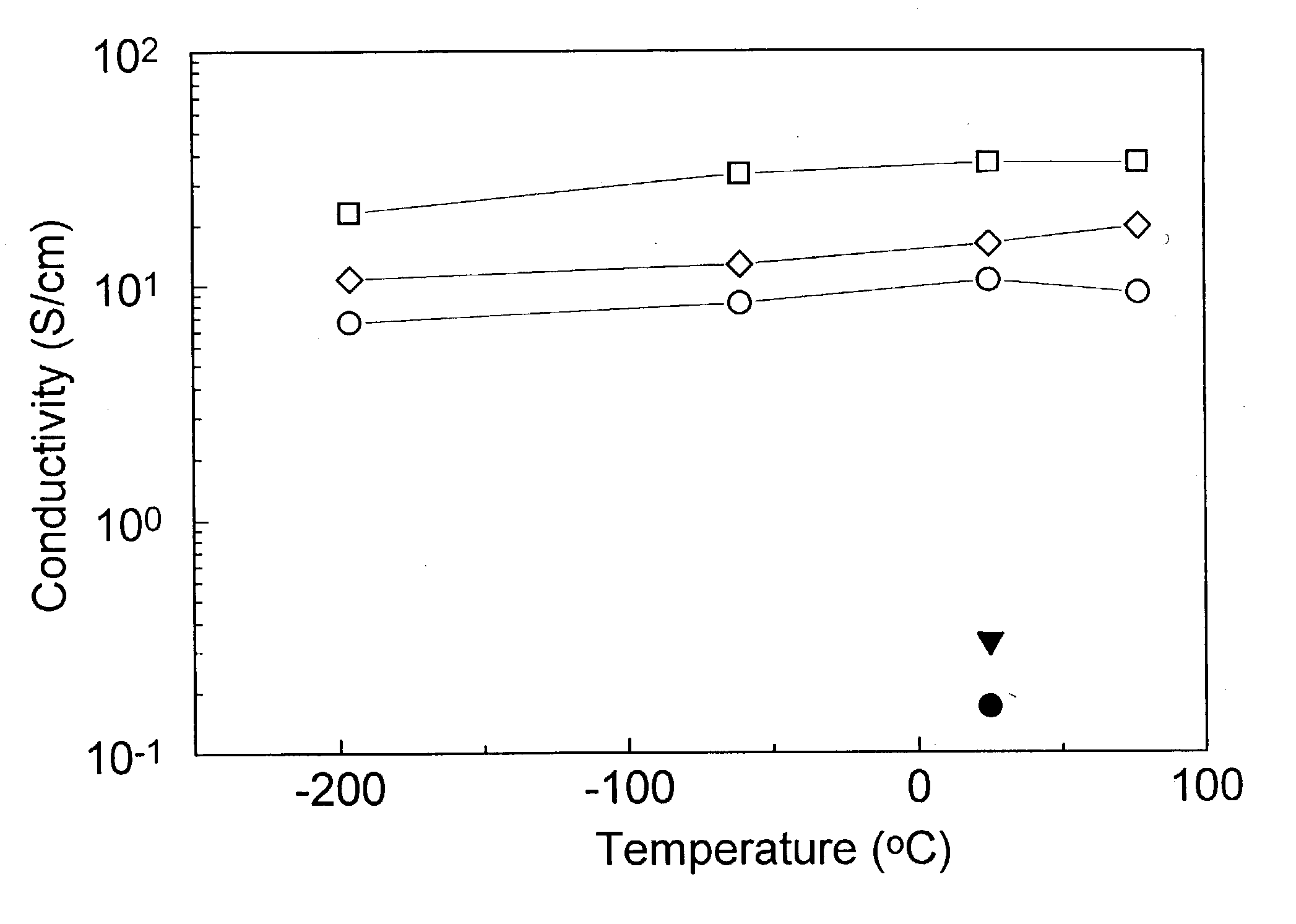

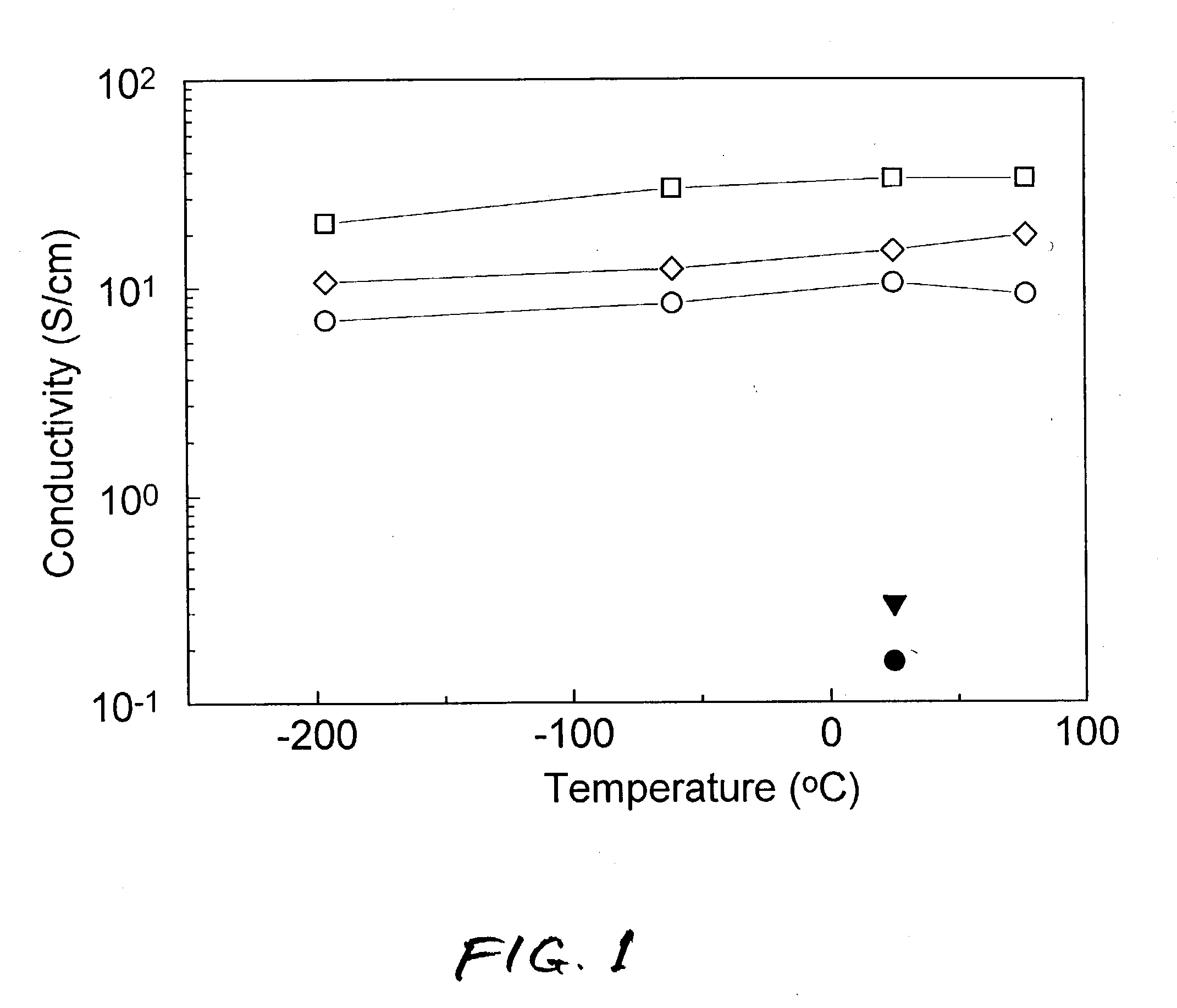

Image

Examples

examples

[0028] Materials, Equipment, and Experimental Procedures

[0029] Purified single-wall carbon nanotubes produced by the HiPco process with more than 90% of the catalyst removed were obtained from Carbon Nanotechnologies Incorporated (Houston, Tex., USA). The nanotubes were in paper form, and once obtained were dispersed in ethanol with the assistance of ultrasound. The ceramic material was nanocrystalline alumina powder. A mixture consisting of 80% α-Al2O3 and 20% γ-Al2O3 with particle sizes of 300 nm (40 nm crystallite size) and 20 nm, respectively, was obtained from Baikowski International Corporation (Charlotte, N.C., USA). In addition, γ-Al2O3 with average particle sizes of 15 nm and 32 nm and synthesized by gas condensation was obtained from Nanophase Technologies Corporation (Darien, Ill., USA).

[0030] For certain experiments, the alumina or alumina mixture was first mechanically activated by high-energy ball milling prior to being combined with the carbon nanotubes. The high-en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com