Robot controller

a robot controller and controller technology, applied in the field of robot controllers, can solve the problems of reducing affecting the safety of workers, and requiring a large amount of time and labor, so as to shorten the time for correcting work programs, improve the efficiency of robot teaching work, and reduce the risk of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[Embodiment 1]

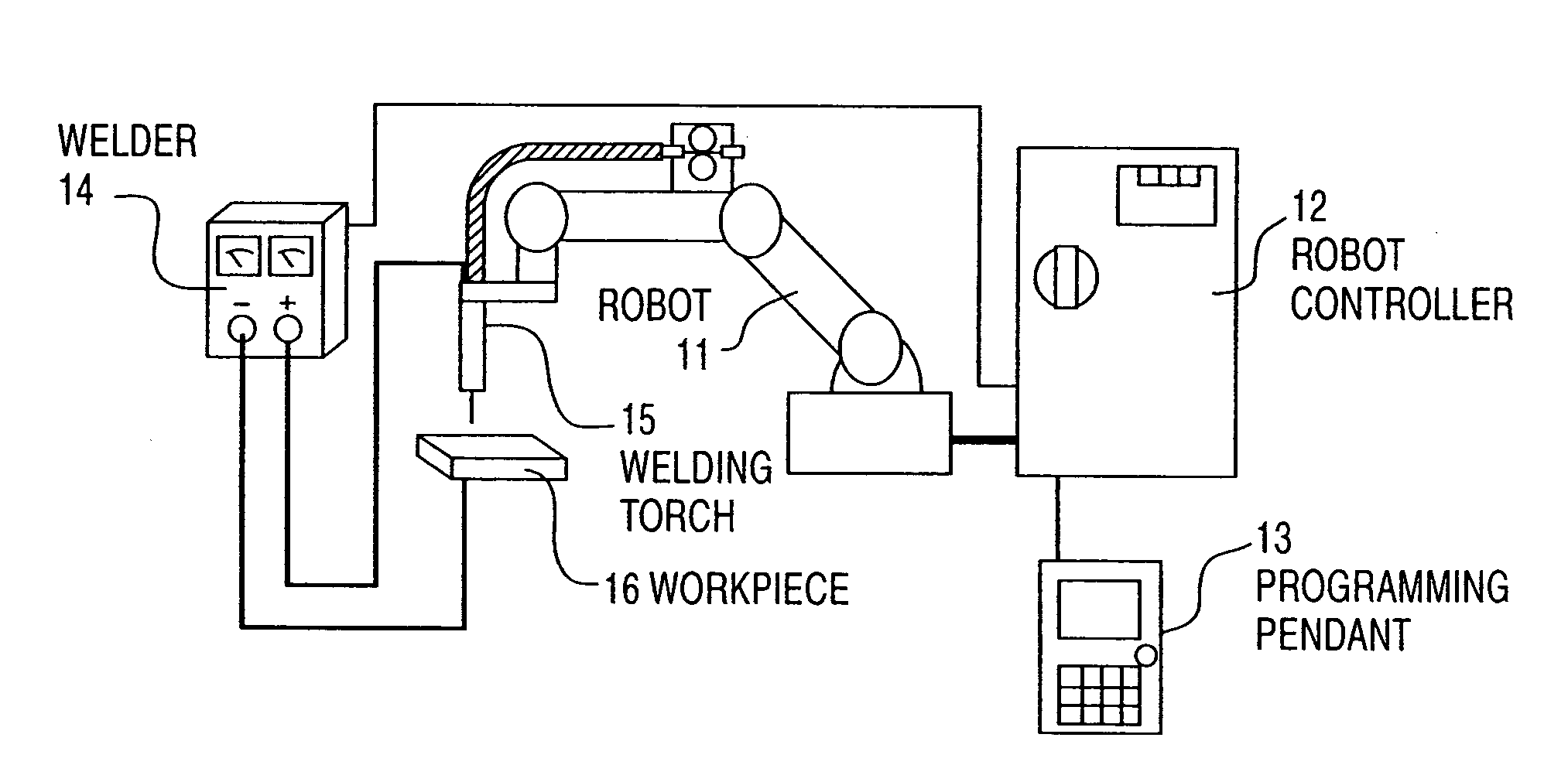

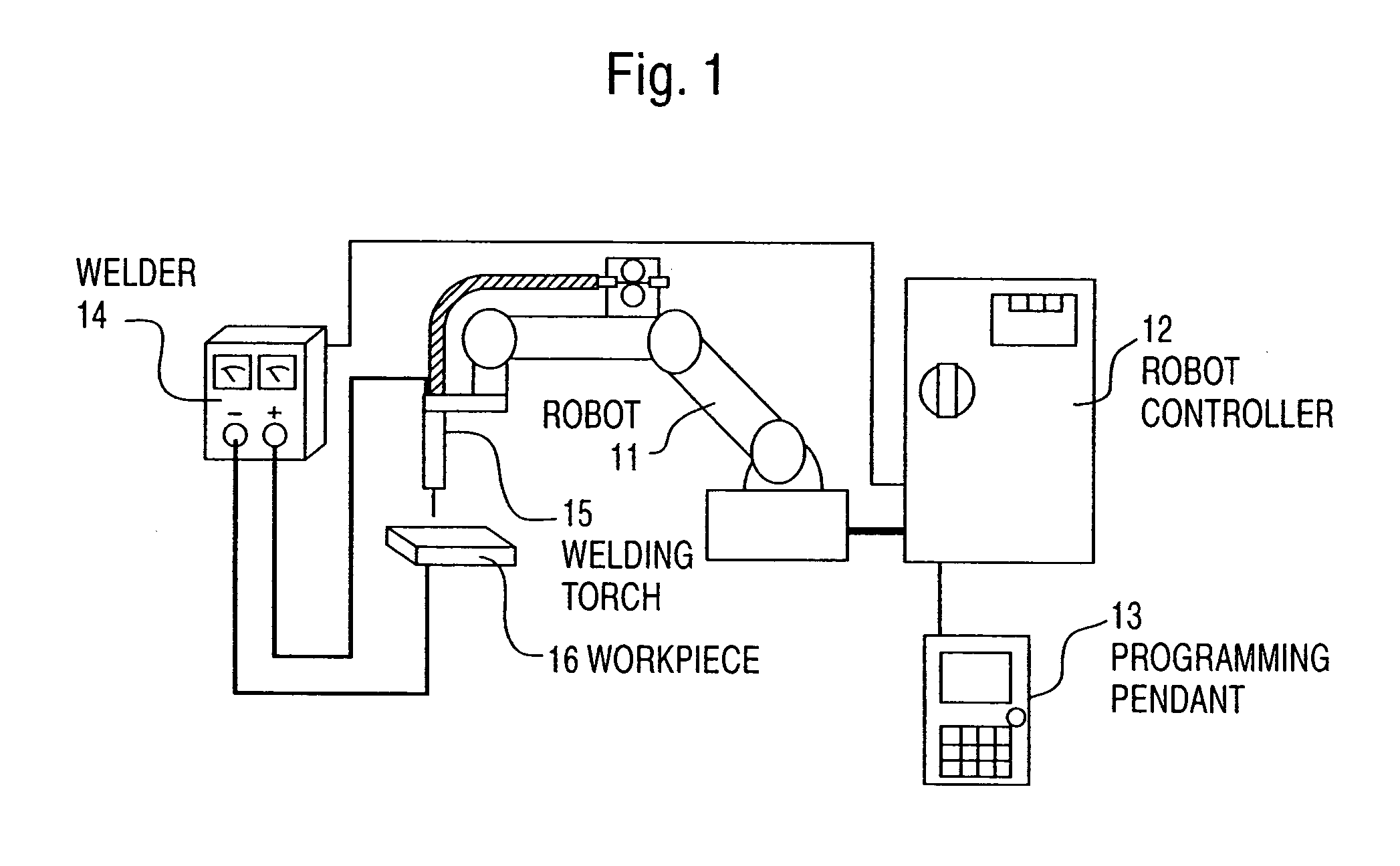

[0046]FIG. 1 is a configurational view of a welding robot system according to the invention. A robot 11 operates by commands from a robot controller 12.

[0047] A programming pendant 13 is a human interface for displaying, preparing and editing states of a robot and work programs. When teaching the robot work, an operator prepares and edits work programs while operating the robot 11 and robot controller 12 by operating the programming pendant 13.

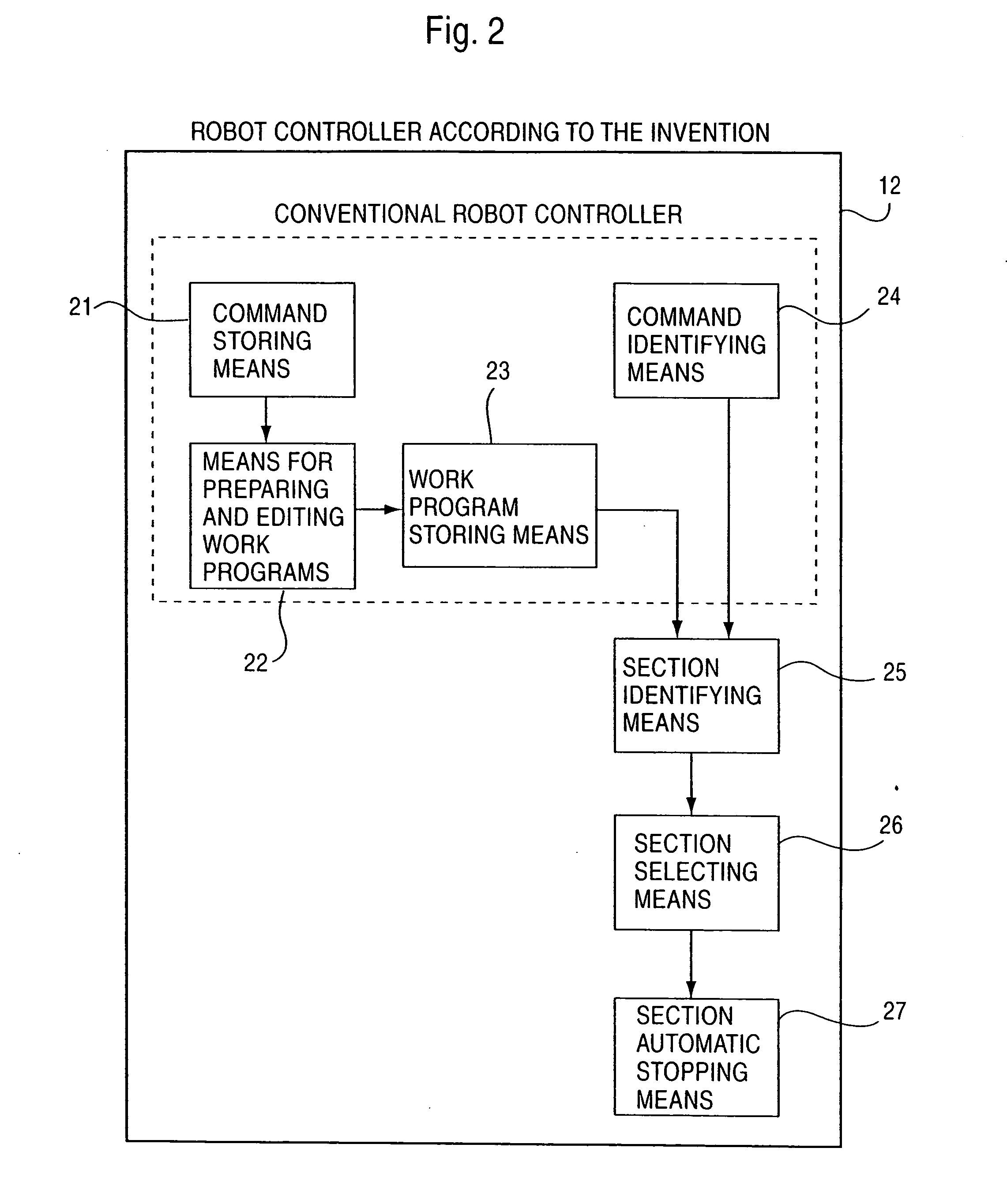

[0048] When a work program is completed and the robot 11 is caused to carry out work, the robot controller 12 actuates the robot 11 as a work program, and at the same time, outputs a command to a welder 14. The welder 14 issues outputs (current and voltage) suited to a command to a welding torch 15 and a workpiece 16 to be welded, and welding is carried out. FIG. 2 is a block diagram showing a construction of the invention. The robot controller according to the invention is comprised of command storing means 21, means 22 for pr...

embodiment 2

[Embodiment 2]

[0063] Next, a detailed description is given of the second embodiment regarding a movement method to correction positions of Step 34 and Step 37 in FIG. 3 with reference to a view showing a work program example in FIG. 7 while comparing a prior art movement method in FIG. 8 with a movement method according to the invention in FIG. 9. FIG. 7 showing a work program example is composed of a movement command and a work command.

[0064] Circle marks shown in FIG. 8 and FIG. 9 indicate the tip end positions of a welding torch 15, respective fine lines therein indicate air-cut sections, respective thick lines therein indicate work sections (welding sections) in which work is carried out while moving, a double line therein indicates a section to be corrected, and an arrow indicates a movement section in which a robot moves by pressing the operation key of the teaching pendant 13 once.

[0065] In addition, figures attached to respective lines in FIG. 8 and FIG. 9 indicate command...

embodiment 3

[Embodiment 3]

[0069] Hereinafter, a description is given of a mode of the invention while taking a welding work as an example, with reference to the drawings.

[0070]FIG. 10 is a configurational view of a welding robot system according to the invention. The robot 11 moves by commands from the robot controller 12. In a welding work section, a command signal is transmitted from the robot controller 12 to a welder 14, and welding is carried out under appointed conditions. Also, work information such as various types of work conditions regarding work programs, work movement information and robot loci is displayed on a display unit 30, wherein it is possible to instantaneously check the work contents of respective work programs. The work information is outputted to a peripheral memory unit 31 such as a personal computer via a communications interface, wherein it is possible to check the work management information. A peripheral work state monitoring unit 32 is a unit that detects a curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| movement | aaaaa | aaaaa |

| movements | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com