Methods and devices to control polymerization

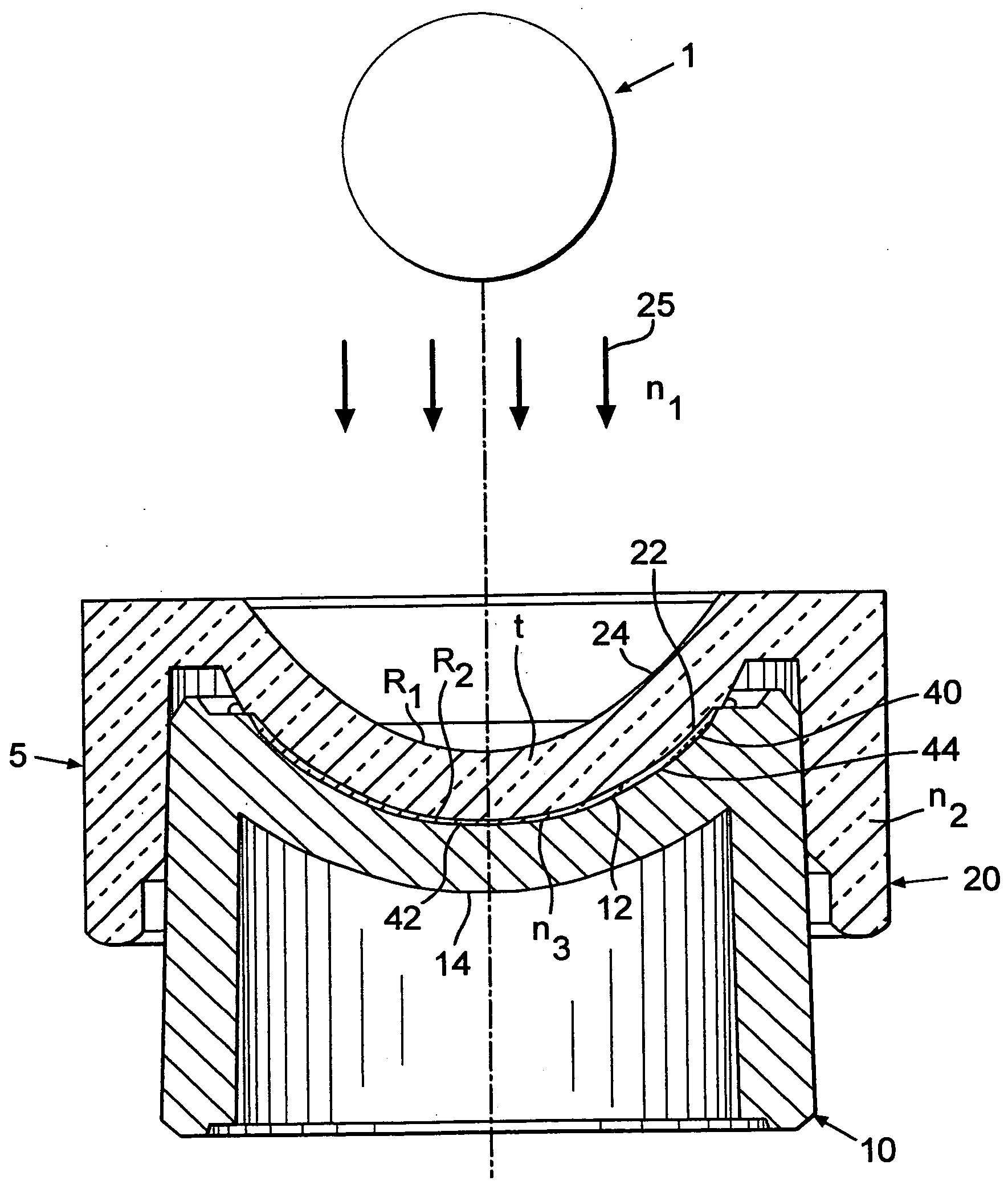

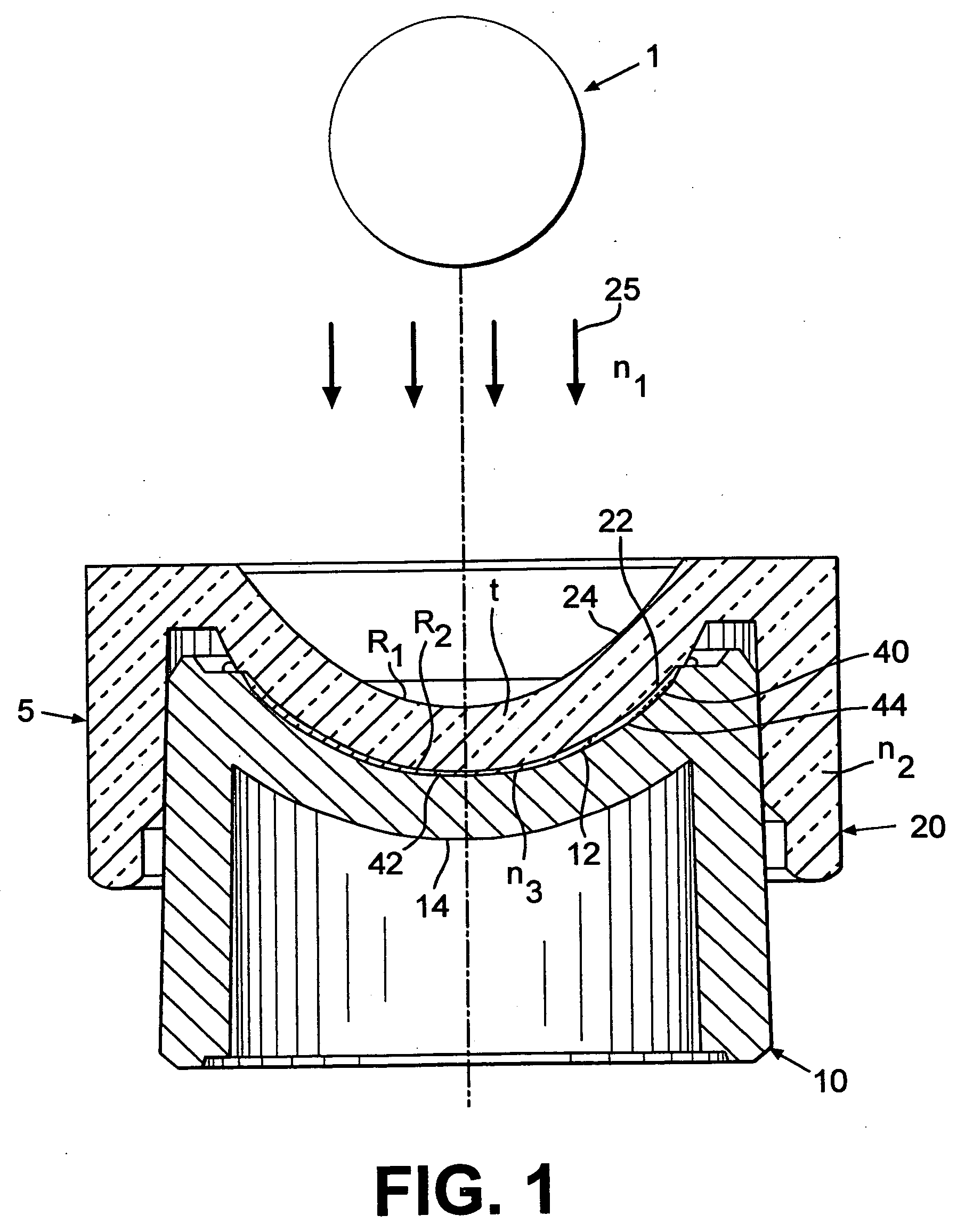

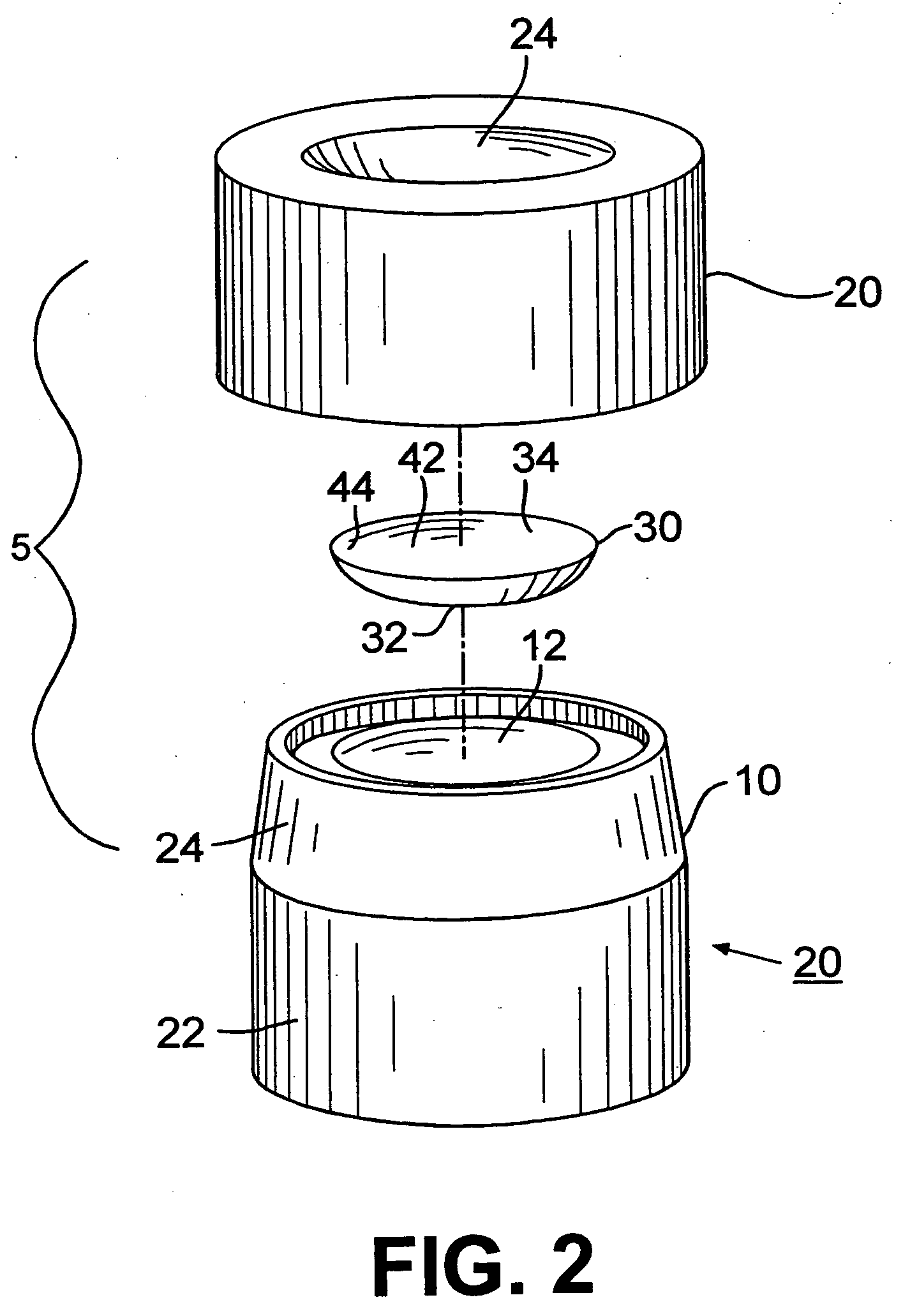

a polymerization and polymerization technology, applied in the field of controlled curing of optical devices, can solve the problems of non-uniform distribution of light intensity over the lens-forming material, non-critical surface of the mold may refract radiation, scattering of light rays,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0061] A series of HEMA lenses was cast molded using posterior and anterior molds made from a non-UV stabilized PVC resin. The posterior mold concave surface of lot 2 was filled with glycerol; the posterior mold concave surface of lot 3 was filled with water. After casting, the mold assemblies were separated and lenses were hydrated and measured. Each lot had five lenses.

TABLE 1Lot #SAG (mm)1 (control)3.01823.59633.600

[0062] Lenses made with water or glycerol in the posterior cavity showed an increased SAG measurement when compared to the control lenses. The lots with increased SAG measurements showed a decrease in the number of lenses exhibiting dimpling.

example 2

[0063] A series of HEMA lenses was cast molded using posterior and anterior molds made from a non-UV stabilized PVC resin. The mold assemblies were separated and lenses were hydrated and measured. Lot 1 had 89 lenses, Lot 2 had 69 and Lot 3 had 27. Lot 3 had a controlled non-critical surface (no junctions present). A 58.8 D magnifier lens was used as the optical lens.

TABLE 2Non-CriticalClampSurfacePlatePower ofAverageLot No.Posterior MoldTreatmentContact LensSAG1 (control)StandardNo−63.298Surface, Bevelcondensinglens2Optical Quality58.8 D−63.372Surface, Bevelcondensinglens3Controlled58.8 D−63.451curvecondensinglens

[0064] The lenses cured with a magnifying lens showed an increase in SAG measurements as compared to the control lenses (lot 1).

example 3

[0065] A series of HEMA lenses was cast molded using posterior and anterior molds made from a non-UV stabilized PVC resin. The mold assemblies were separated and lenses were hydrated and measured. Each lot had 5 lenses. Lot 1 was a control lot. An asymmetric convex plug having a power of 117 D made of Topas was inserted into the posterior concave surface of lot 2. The surface of the plug toward the optical source had a radius of 7.00 mm and the surface of the plug facing the non-critical surface of the mold had a radius of 8.5 mm. The SAG of the plug was 4.68 nm.

TABLE 3Lot No.SAG (average)1 (control)3.53423.658

[0066] The lenses made using an asymmetric convex plug made of Topas inserted showed an increase in SAG measurement and a lower incidence of dimpling. Overall, improved lenses were produced using the Topas insert.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com