EUV light source optical elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

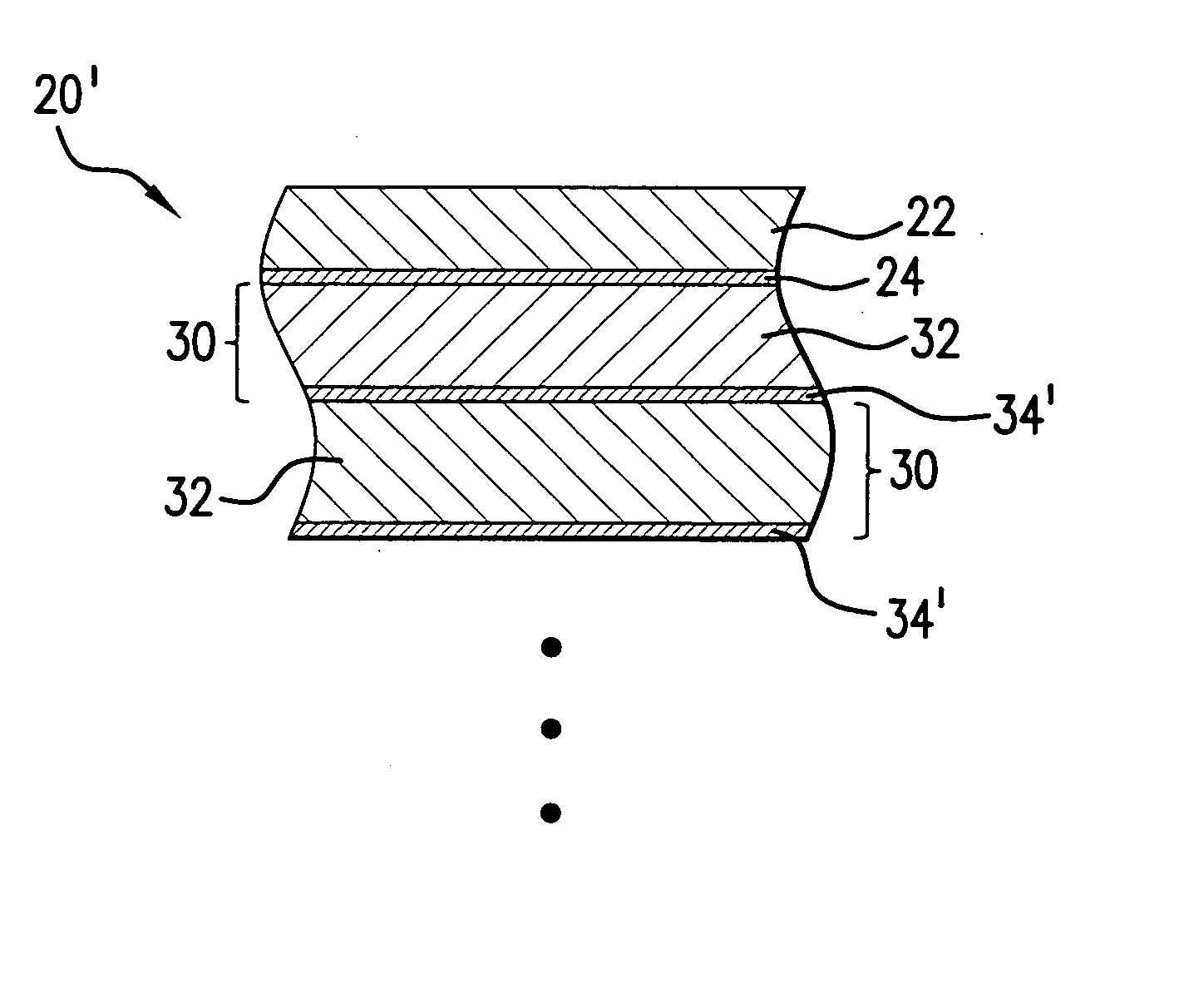

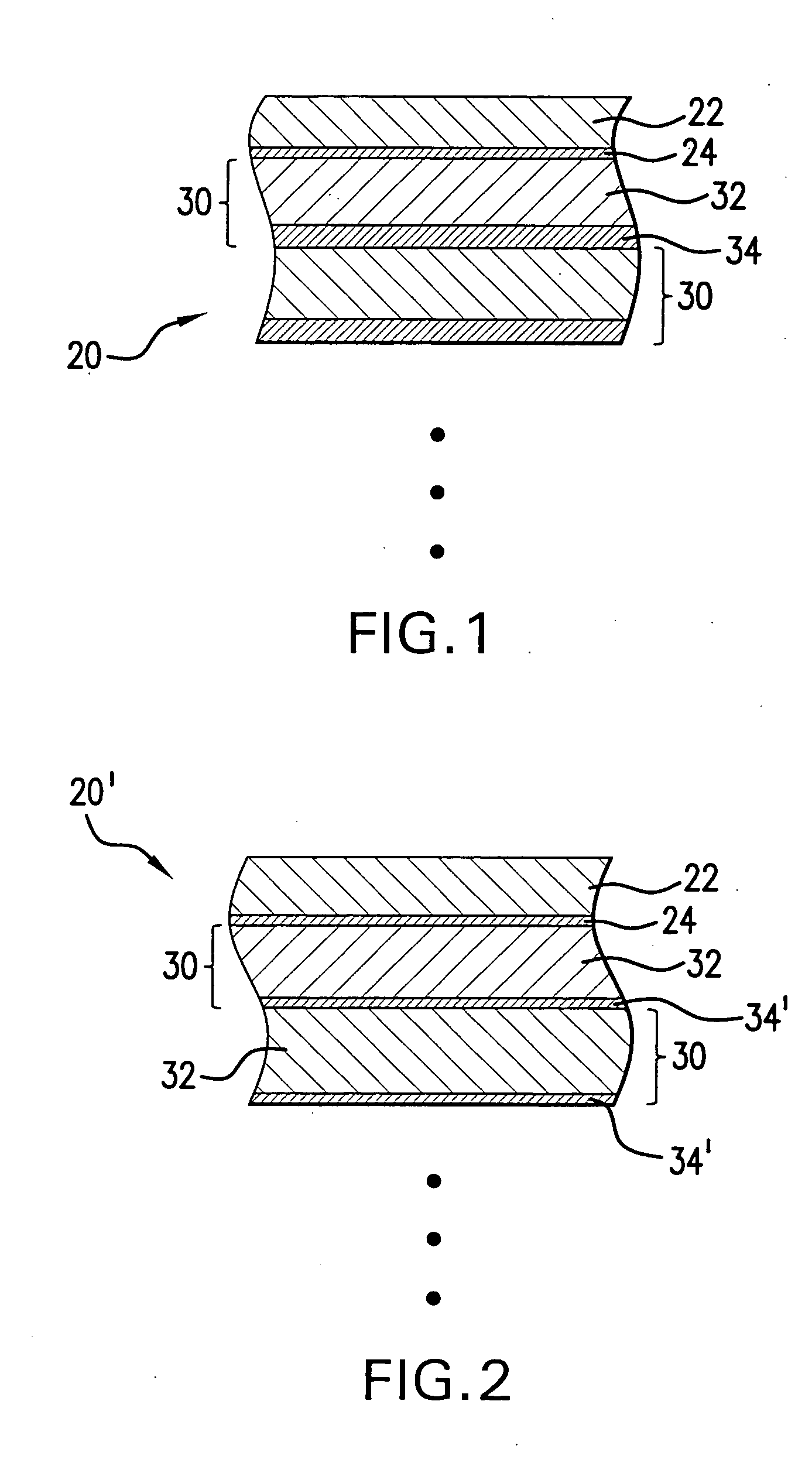

[0024] Turning now to FIG. 1 there is shown schematically and not to scale a prior art MLM 20 structure and composition including a ruthenium capping layer 22 and an underlying intermediate layer 24, which may be, e.g., a source material diffusion barrier layer 24, which may be selected for its resistance to diffusion of a selected material, or its compounds, e.g., the source material for the EUV plasma, e.g., lithium. The MLM 20 may comprise be made up of a plurality of binary layers 30 made up of an absorber layer, e.g., a molybdenum layer 32 and a spacer layer 34 e.g., of silicon.

[0025] Source material diffusion through the diffusion barrier layer 24 and into the binary layer(s) 30 and the formation between the layers 32 and 33 of a source material silicide, e.g., lithium silicide, which can cause, e.g., a roughness of the Mo and / or Si at the Mo / Si interface. This can detract from the binary layers 30 thermal stability at elevated temperatures, and also impact the reflectivity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com