Power module package having excellent heat sink emission capability and method for manufacturing the same

a technology of power module and heat sink, which is applied in the field of semiconductor devices, can solve the problems of complex and costly manufacturing process of power module packages b>10/b>, power circuit chips generate much more heat, and achieve the effect of simple and low cost method of automated manufacturing and excellent heat dissipation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

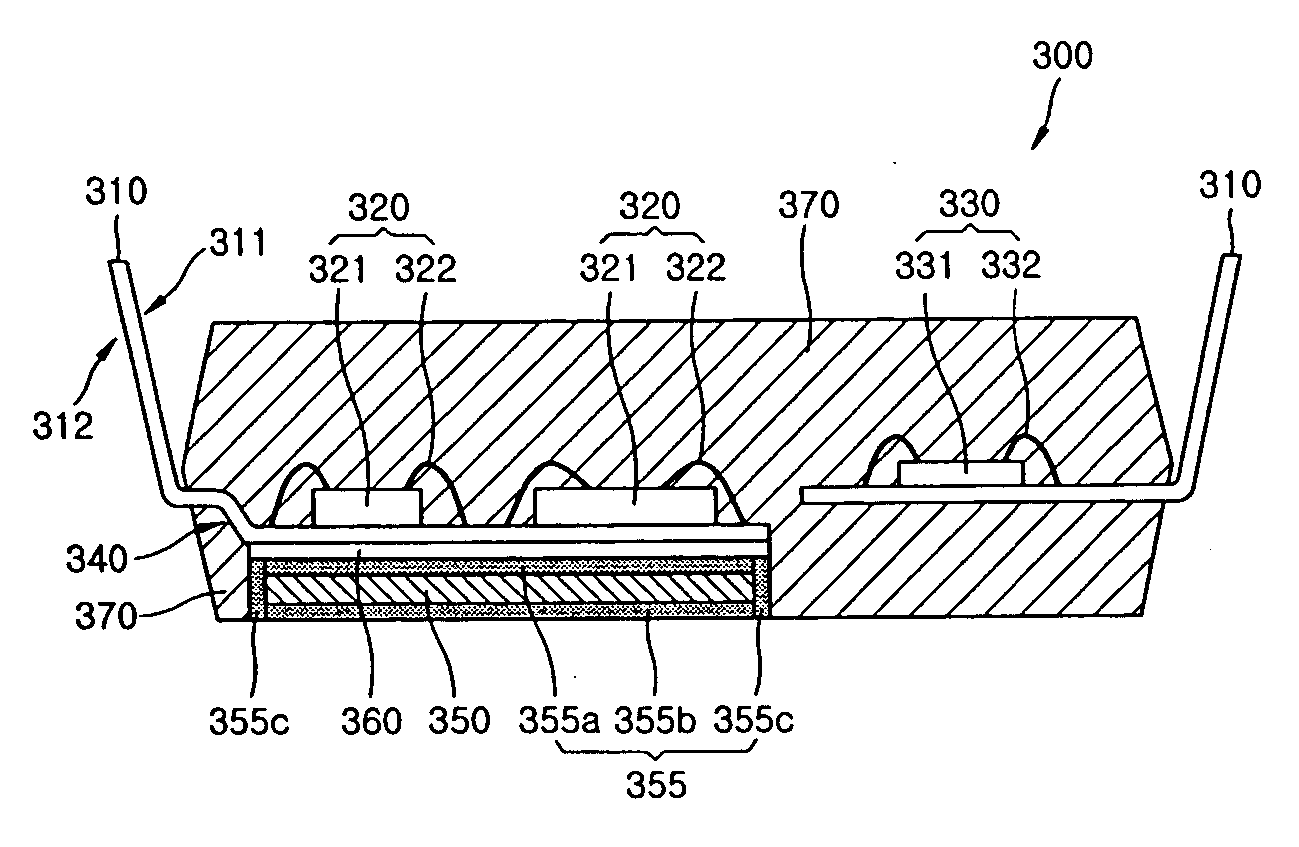

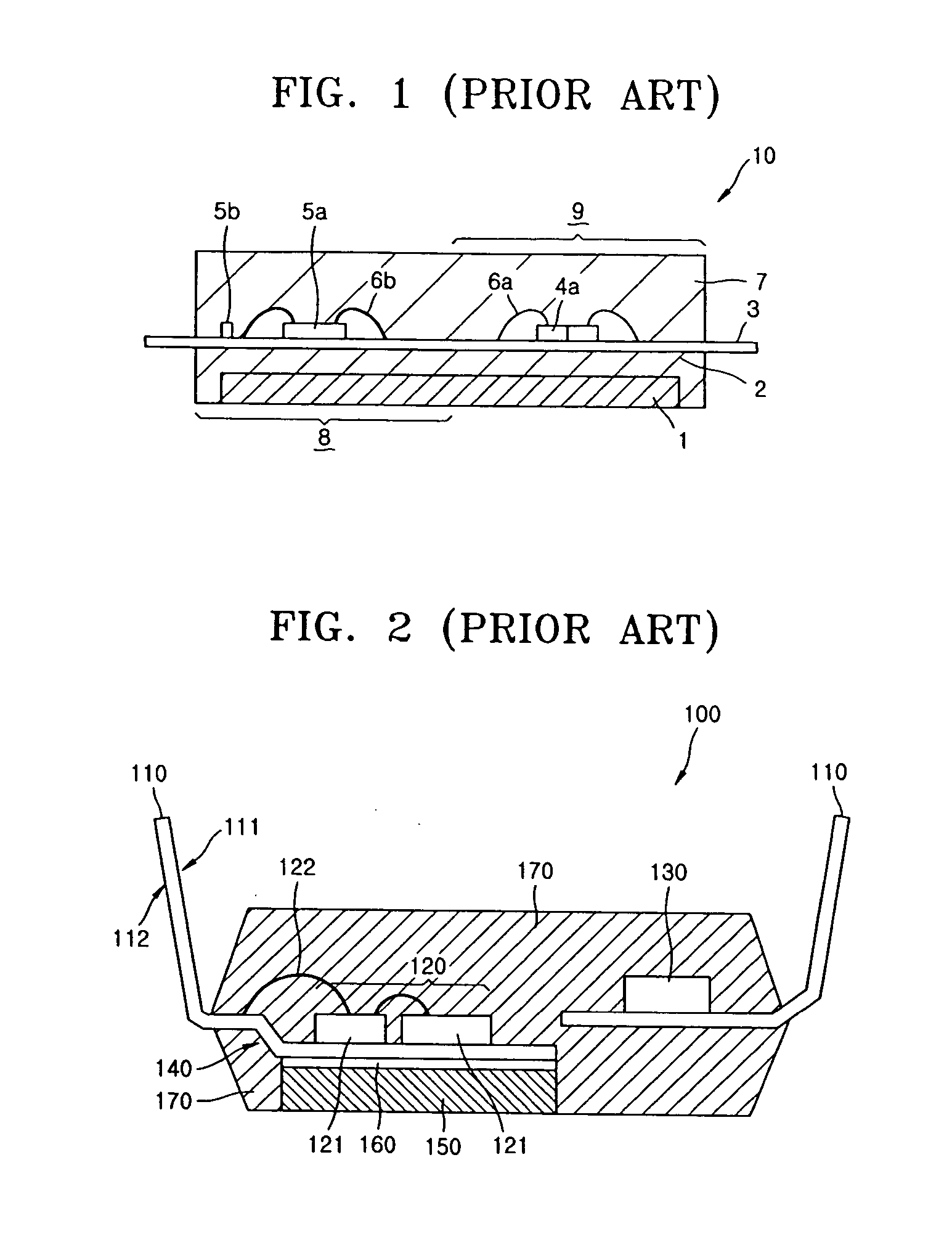

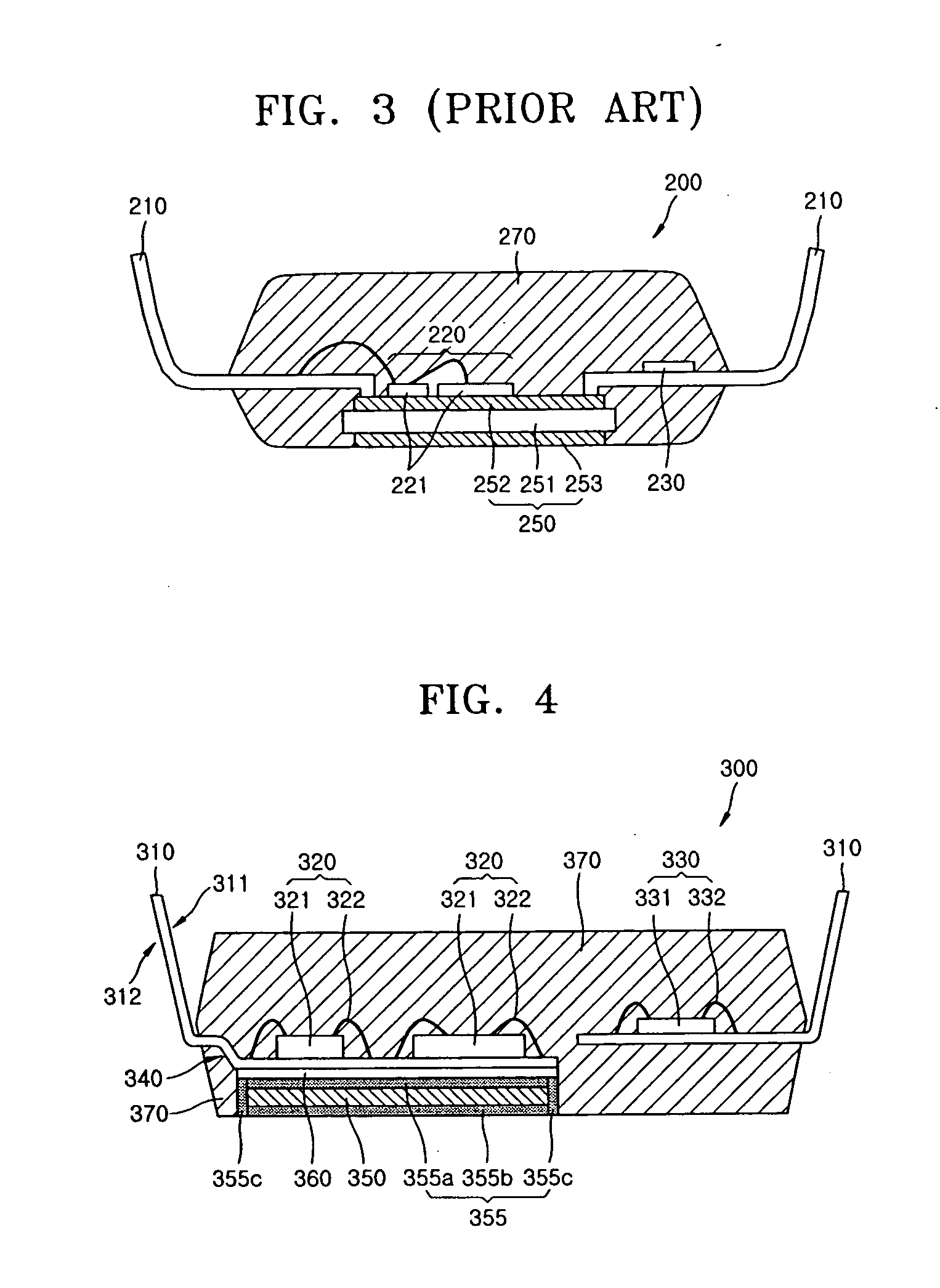

[0041]FIG. 4 is a schematic, cross-sectional view of a power module package according to the present invention.

[0042] Referring to FIG. 4, a power module package 300 includes: a lead frame 310; a power circuit element 320; a control circuit element 330; a metal / metal oxide substrate 350, 355; and an EMC 370.

[0043] The power circuit element 320 includes one or more power circuit chips 321 with aluminum wire 322 to connect the chips 321 to the leads of the lead frame. The aluminum wire 322 has a diameter of about 250-500 μm to endure a high rated current. The control circuit element 330 includes a control circuit chip 331 and a gold wire 332. The aluminum wires 322 and the gold wires 332 properly connect the power circuit chip(s) 321 and the control circuit chip 331, respectively to the leads of the lead frame 310 that extend from inside the package 300 to the outside.

[0044] The lead frame 310 has a thickness of about 0.5-1 mm and has a first surface 311 on which the circuit element...

second embodiment

[0062]FIG. 11 is a flowchart explaining an example of a method for manufacturing a power module package according to the present invention.

[0063] First, aluminum / aluminum oxide substrate 455 is prepared (S21). The aluminum / aluminum oxide substrate 455 includes the heat sink 450 and at least one insulation layer 455a made of the aluminum oxide and formed at least on an upper surface of the heat sink 450. The insulation layer 455a may be formed over an entire surface of the heat sink 450. The aluminum / aluminum oxide substrate 455 may be manufactured by performing a general aluminum oxidation operation known or anodizing. Such anodizing processes are well known.

[0064] The upper wiring layer 452 is directly formed on the insulation layer 455a (S22). The upper wiring layer 452 may be formed on the aluminum oxide layer 455 by a lamination method using Cu, Cu / Ni, Cu / Au, or Cu / Ni / Au, or a sputtering method using the above metal. The upper wiring layer 452 has a properly-shaped wiring patte...

sixth embodiment

[0081]FIG. 9 is a cross-sectional view of one example of a semiconductor package 800 according to the present invention. Referring to FIG. 9, a semiconductor package 800 includes aluminum / aluminum oxide substrate 855, 858, a wiring pattern 852a, external connection pads 852b, a semiconductor element 830, and a sealing resin 870.

[0082] The semiconductor package 800 according to the sixth embodiment is similar in its structure to a flip chip semiconductor package. One difference is that aluminum / aluminum oxide substrate 855, 858 includes an electrical insulation layer 855 made of a plate of aluminum oxide and a plurality of vias 858 made of non-oxidized aluminum that pass through the insulation layer 855. The aluminum / aluminum oxide substrate 855, 858 can be formed by masking an aluminum plate and oxidizing the opposed aluminum to create the vias 858.

[0083] The wiring pattern 852a connected with one end of the vias 858 is formed on a first surface of the aluminum / aluminum oxide subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesivity | aaaaa | aaaaa |

| Electric properties | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com