Method of manufacturing carbon nanotube field emission device

a carbon nanotube and emission device technology, applied in the field of carbon nanotube field emission device manufacturing, can solve the problems of reducing the work function, limiting the life span of such a micro tip, and not being able to achieve cvd at a low temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, a method of manufacturing a carbon nanotube emitter and a method of manufacturing a field emission device adopting the carbon nanotube emitter according to embodiments of the present invention will be described in detail with reference to the attached drawings. In the drawings, a field emission device including carbon nanotubes is exaggerated for clarity. In particular, one element may be illustrated larger than other elements when necessary and may be omitted to more clearly describe the embodiment.

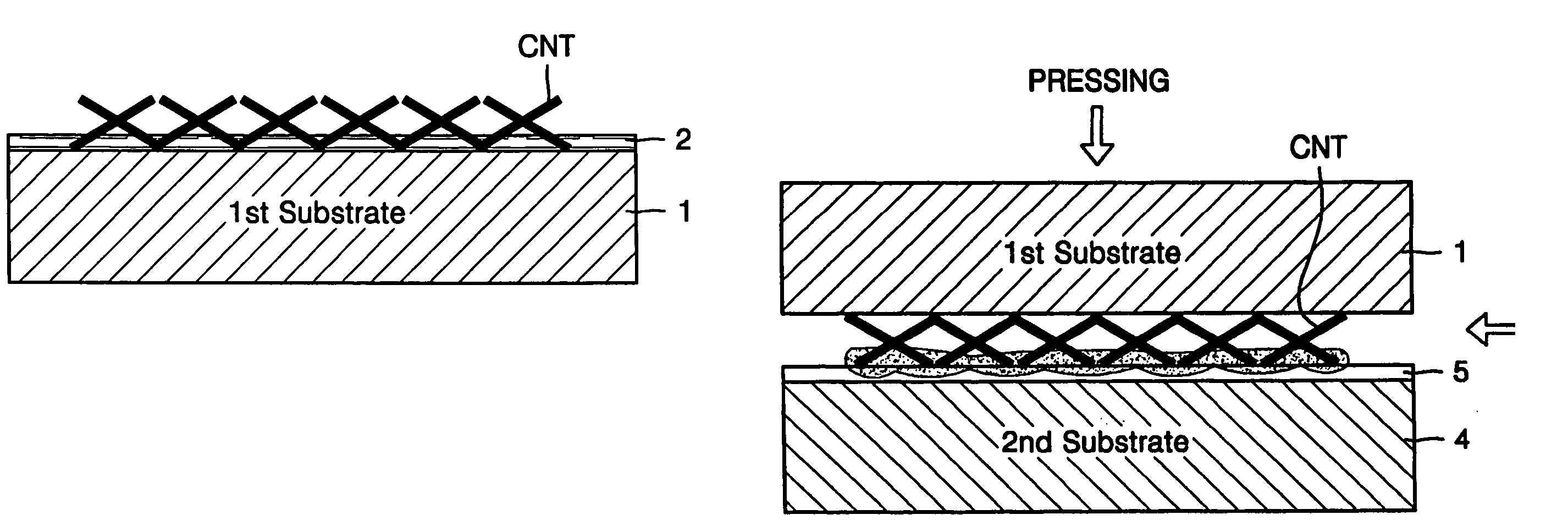

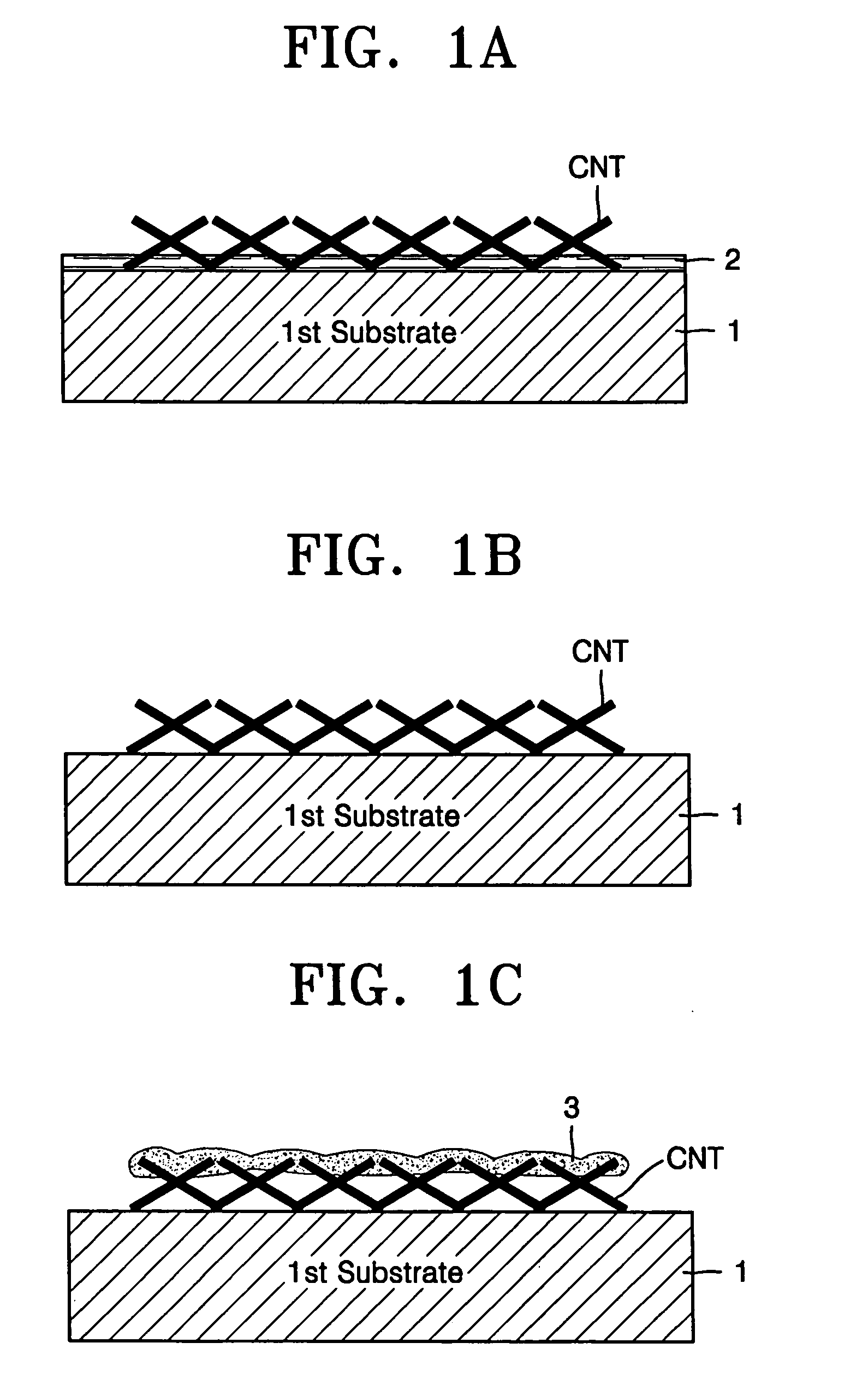

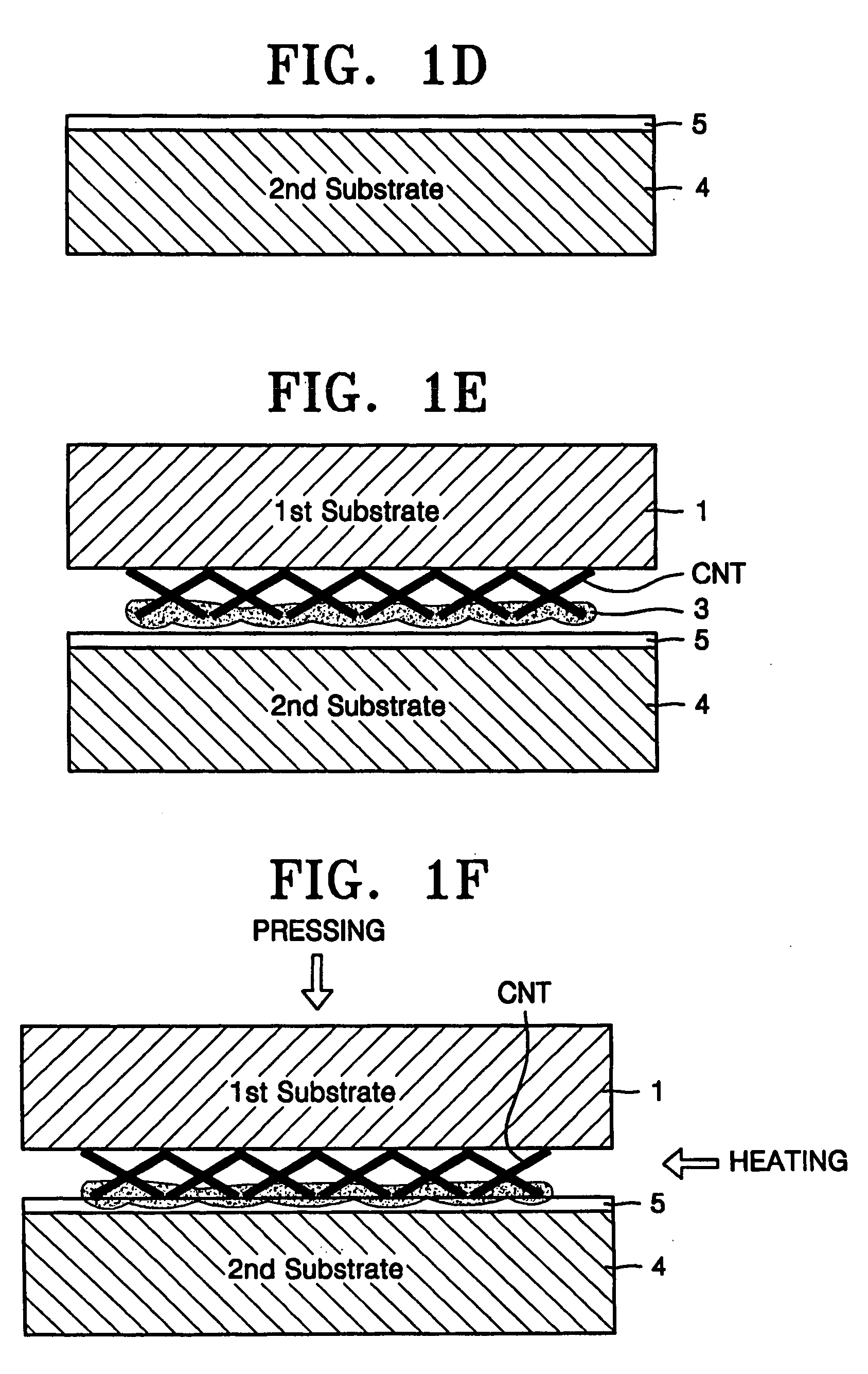

[0033]FIGS. 1A through 1I illustrate a method of manufacturing a carbon nanotube emitter, according to an embodiment of the present invention.

[0034] As shown in FIG. 1A, carbon nanotube powder is mixed with an organic dispersing agent, for example, ethanol, or an inorganic dispersing agent, for example, water 2. Next, the mixture is coated on the surface of a first substrate 1 formed of Si or sodalime glass.

[0035] As shown in FIG. 1B, the dispersing agent 2 is remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com