Low pH lactic acid fermentation

a technology of lactic acid fermentation and low ph, which is applied in the field of low ph lactic acid fermentation, can solve the problems of fermentation not providing lactate enriched in either optical isomer, and the inhibition of end-products by organic acids (lactic acid), and achieves poor growth, high productivity free lactic acid producers, and high concentrations of free lactic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Standard Fermentation Conditions

[0077] Unless otherwise indicated, the fermentation reactions described in the following examples were run using a variety of growth media according to the following standard protocol.

[0078] Cells (250 ul) were passed from a bench stock of the particular strain in 40% tomato juice / 40% LSW-MRS agar bottom phase / MRS top phase biphasic (TJ-SW-MRS biphasic) into fresh TJ-SW-MRS biphasic medium and incubated under static conditions for 18-24 hours at 47° C.

[0079] MRS Medium (pH=6.2)

10g / Lpancreatic digest of gelatin8g / Lbeef extract4g / Lyeast extract20g / Lglucose2g / LK2HPO41g / LTweenR 805g / Lsodium acetate5g / Lammonium citrate0.2g / LMgSO40.05g / LMnSO4

[0080] A 1.0 ml aliquot of the incubate in the fresh TJ-SW-MRS biphasic medium was used to inoculate 80 ml of Medium B supplemented with 10% CSL, glucose (60 g / L total concentration) and calcium carbonate (20 g / L) in a sealed serum bottle and incubated with agitation 18 hours at 47° C. in an environmental shaker.

[...

example 2

Isolation of Acid-Tolerant Homolactic Strains Without pH Control

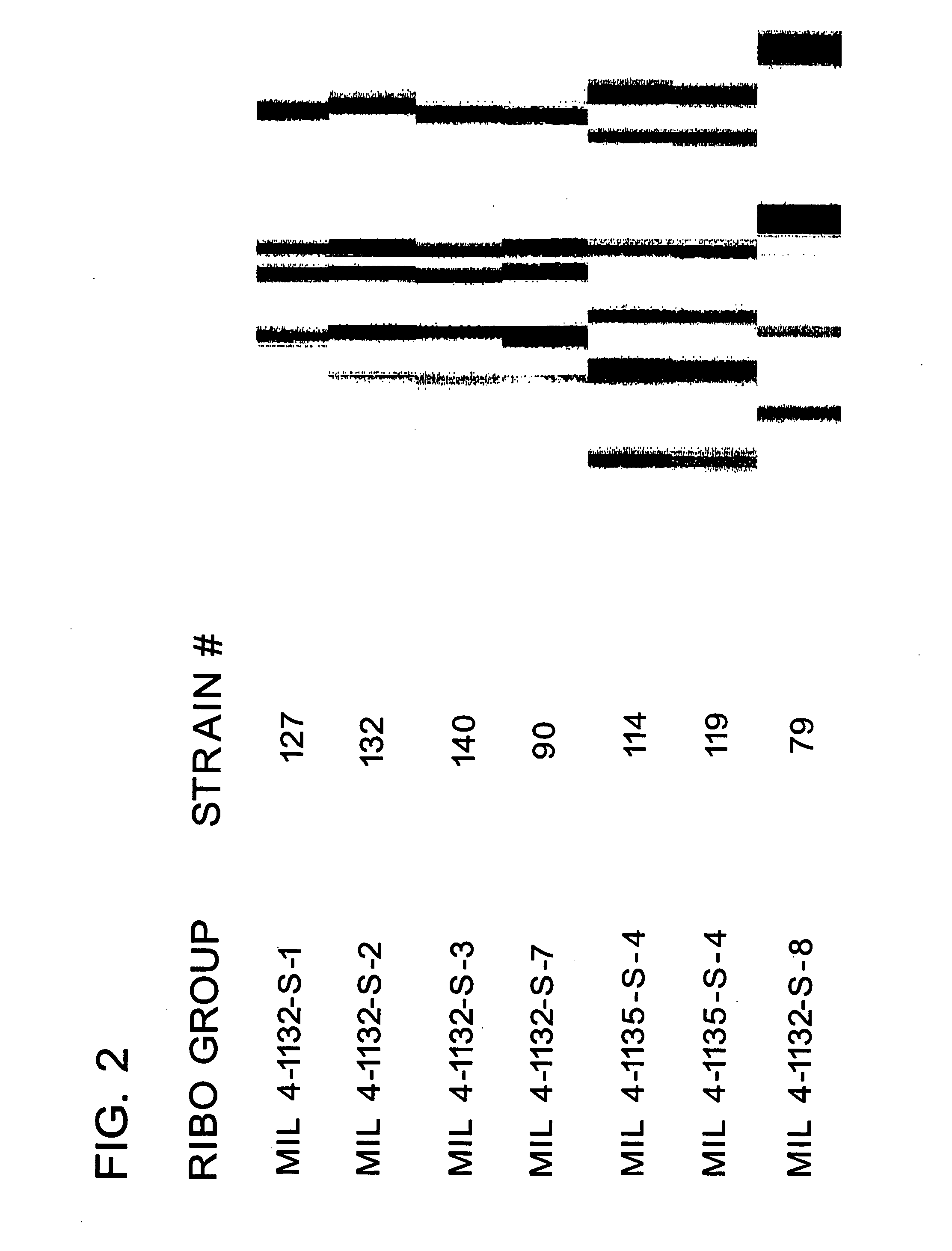

[0083] Homolactatic bacterial strains were isolated from samples of corn steep water obtained from eight different industrial corn milling facilities. The facilities were located in Blair, Nebraska; Edyville, Iowa; Cedar Rapids, Iowa; Dayton, Ohio; Memphis, Tenn.; Istanbul, Turkey; Tillbury, England; and Bergen Op Zoon, the Netherlands.

[0084] The strains were isolated by obtaining samples of steep water from commercial corn milling facilities. The samples were plated on 10% CSL-MRS agar plates (pH 5.0) and incubated anaerobically at 47° C. Colonies were restreaked for isolation on 10% CSL-MRS agar plates. Isolates were then passed into a 40% LSW-40% tomato juice-MRS bottom phase / MRS top phase biphasic medium (pH 6.0) for maintenance purposes. The isolated strains were screened for heterolactic production by monitoring for the formation of gas (CO2) in the bottom of the tube. The homolactic isolates were then screened ...

example 3

Isolation of Acid-Tolerant Homolactic Strains Using Added Base

[0087] An additional set of homolactic strains were isolated from corn steep water samples obtained from the corn milling facilities in Edyville (Iowa), Cedar Rapids (Iowa), and Blair (Nebr.). The isolation procedure employed was the same as described in Example 2. The isolated homolactic strains were characterized based on fermentations carried out in Medium B supplemented with 10 vol. % CSL, 90 g / L glucose and 33 g / L CaCO3. The overall lactate production and / or percentage L-lactate produced were measured for this set of strains. The results are shown in Table 2 below.

TABLE 2Isolated Homolactic StrainsStrain No.g / L Lactate% L-Lac.9062819267.9599562.47449963.177810358.537510465.187510966.268311458.64611747.996212749.544412968.757713259.129513360.379513428.876313654.14113966.084714057.1894

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com