Peltier cooling systems with high aspect ratio

a cooling system and aspect ratio technology, applied in the field of semi-conductor cooling systems, can solve the problems of preventing new use of peltier elements, inefficient use of rectilinear peltier elements to cool point-type heat sources, and difficult to effectively couple a large planar surface to a point-type heat source, etc., to achieve high aspect ratio, low footprint, and concentrated cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

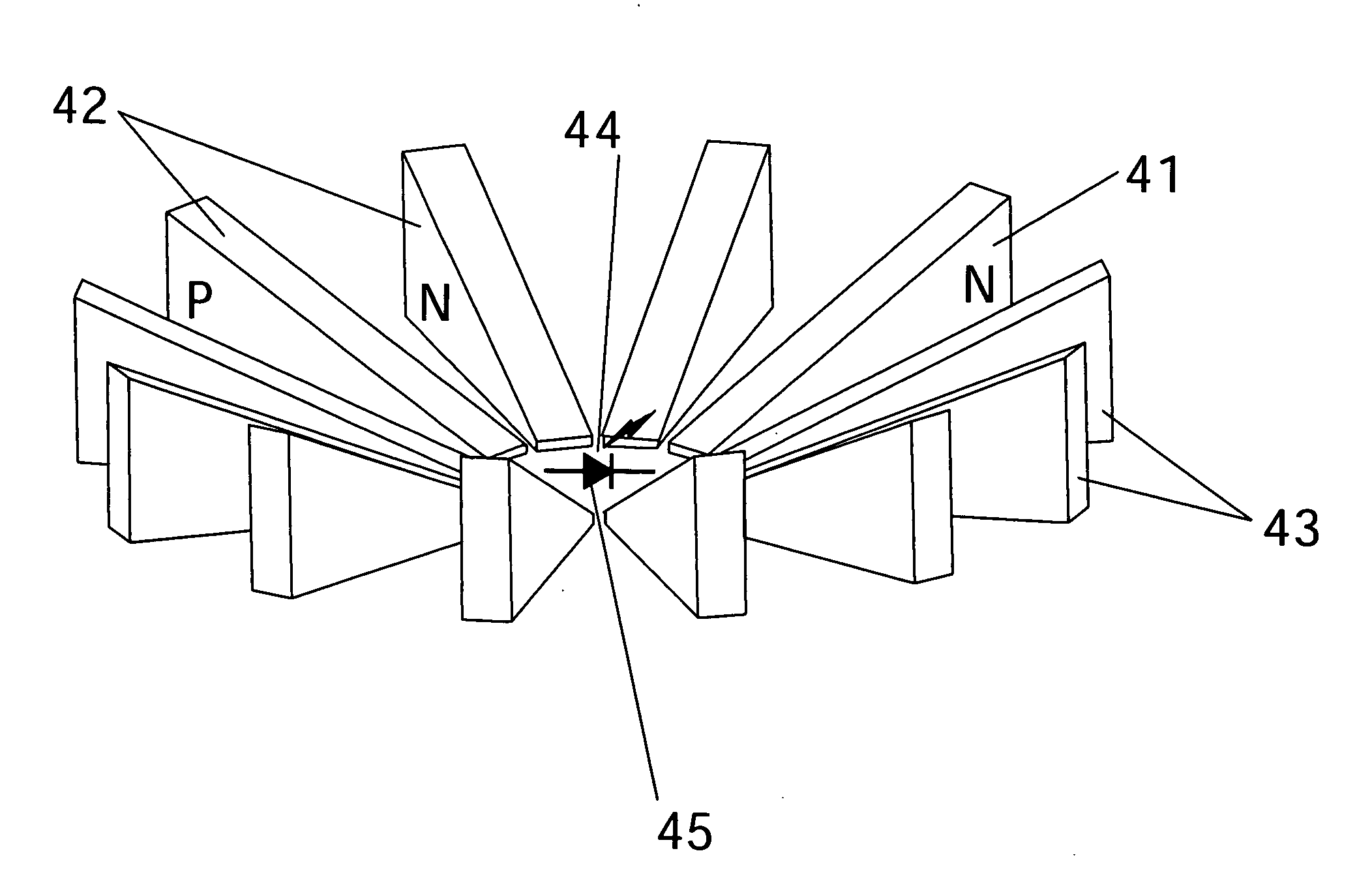

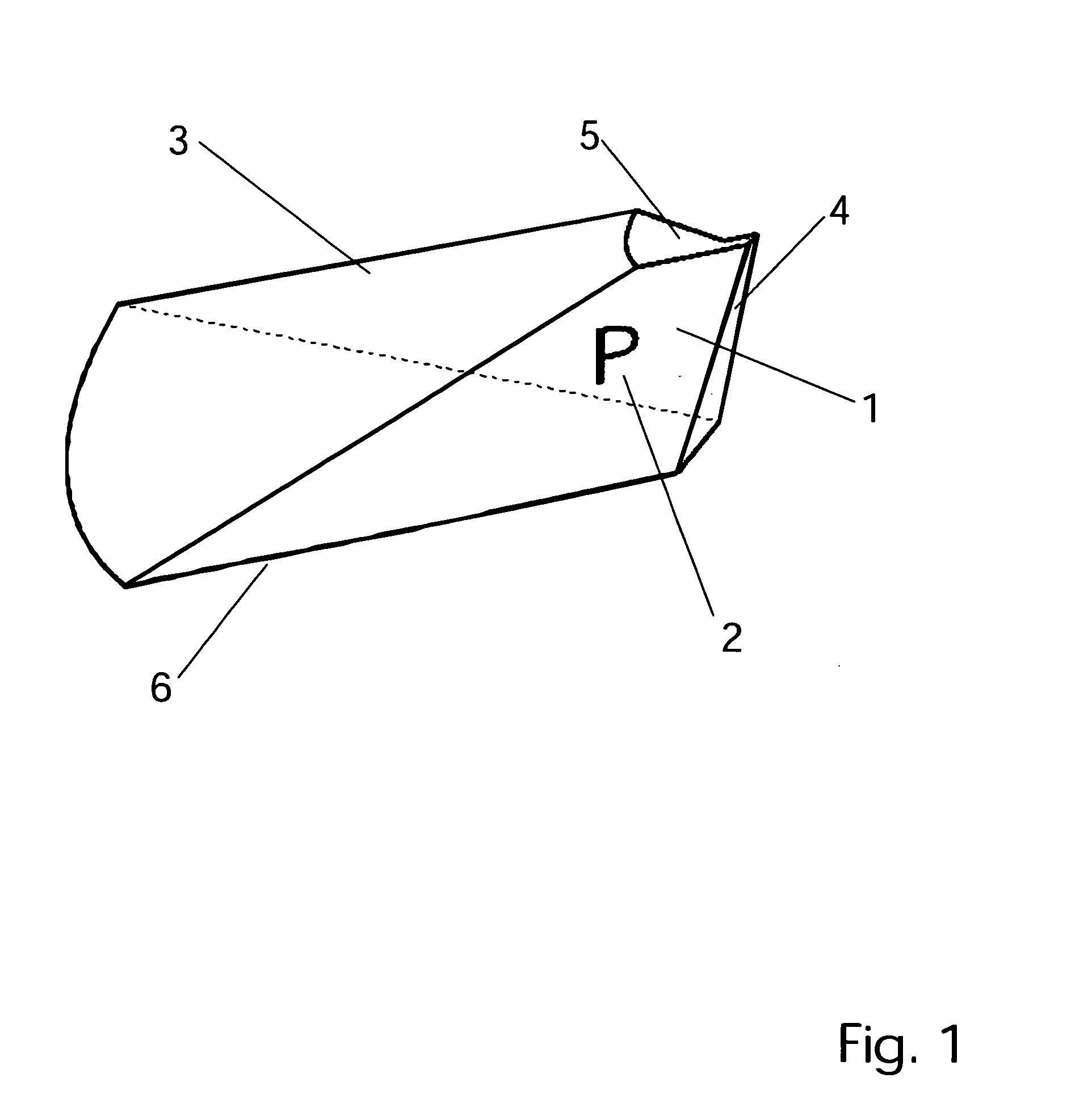

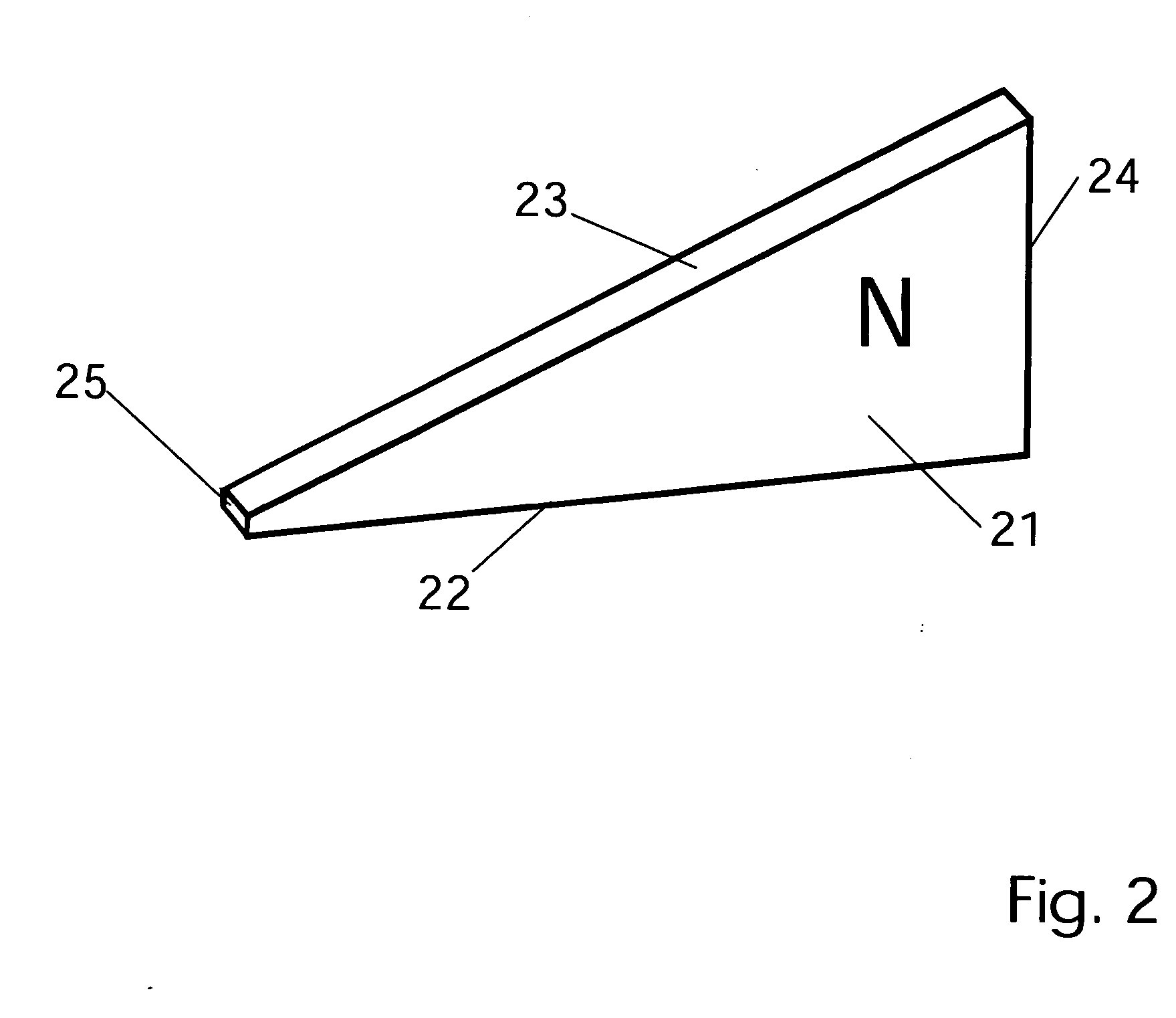

[0041] In accordance with each of preferred embodiments of these inventions, there is provided asymmetric Peltier heat transfer systems where the asymmetry is a spatial arrangement which favors the cold side of system being smaller in size than the hot side. This is achieved by providing Peltier elements of remarkable and unusual shapes in comparison to those which may be found in the art. Typically, Peltier elements are grown as crystals and are nearly invariably formed as cubes or at least rectangular-cylindrical in shape. In the special devices first presented herein, Peltier elements are fashioned from bulk material into shapes which are not rectangular-cylindrical.

[0042] It will be appreciated that each of embodiments described include an apparatus and that the apparatus of one preferred embodiment may be different than the apparatus of another embodiment.

[0043] Peltier cooling systems are typically comprised of alternately doped semiconductor elements. These semiconductor el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com