Modular infrared irradiation apparatus and its corresponding monitoring devices

a module infrared irradiation and monitoring device technology, applied in the direction of heating types, combustion processes, domestic heating details, etc., can solve the problems of loss of control of flame and equipment explosion, reducing process efficiency, and inner burning, so as to enhance the global efficiency of thermal energy and improve control during operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

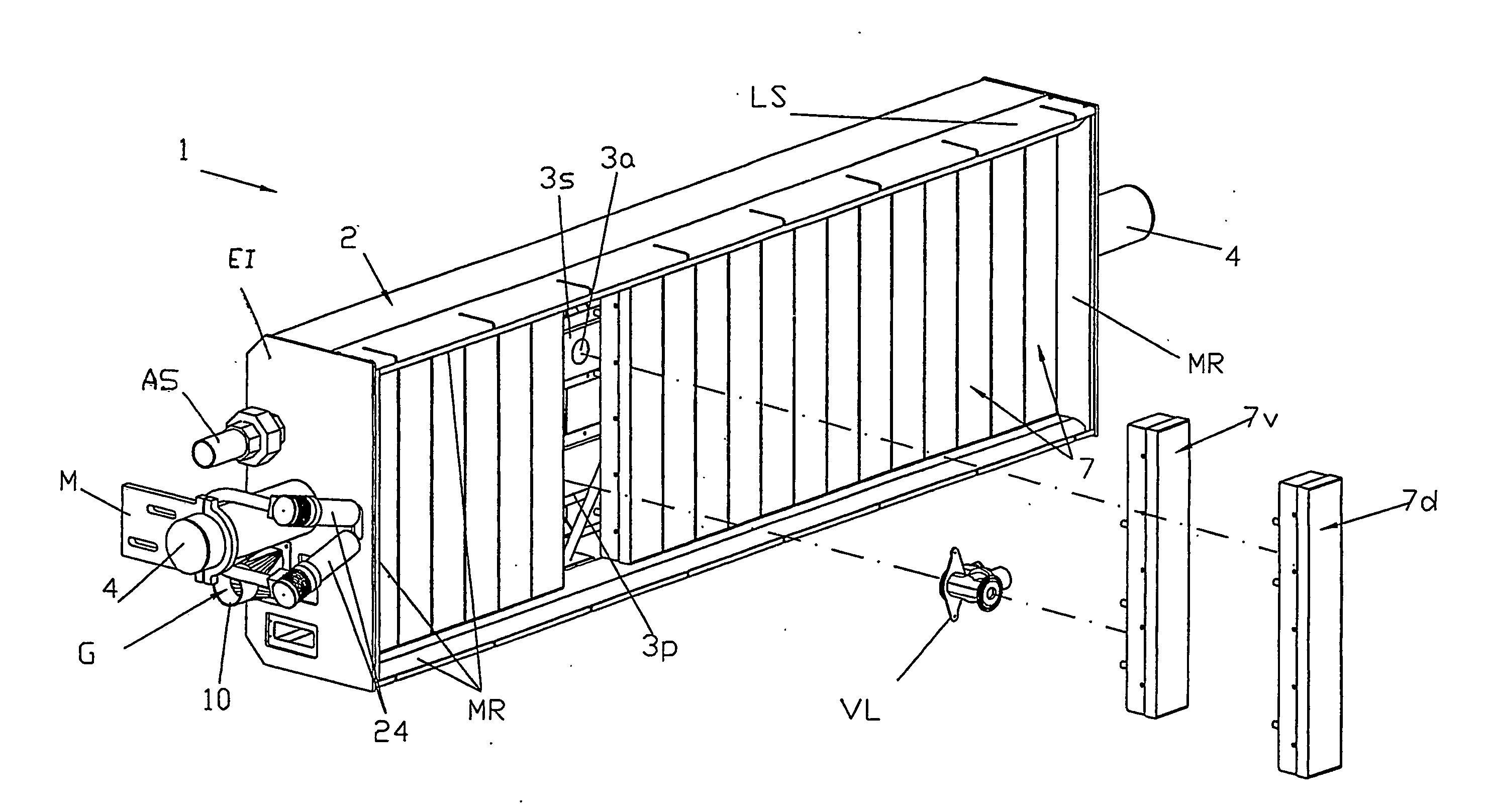

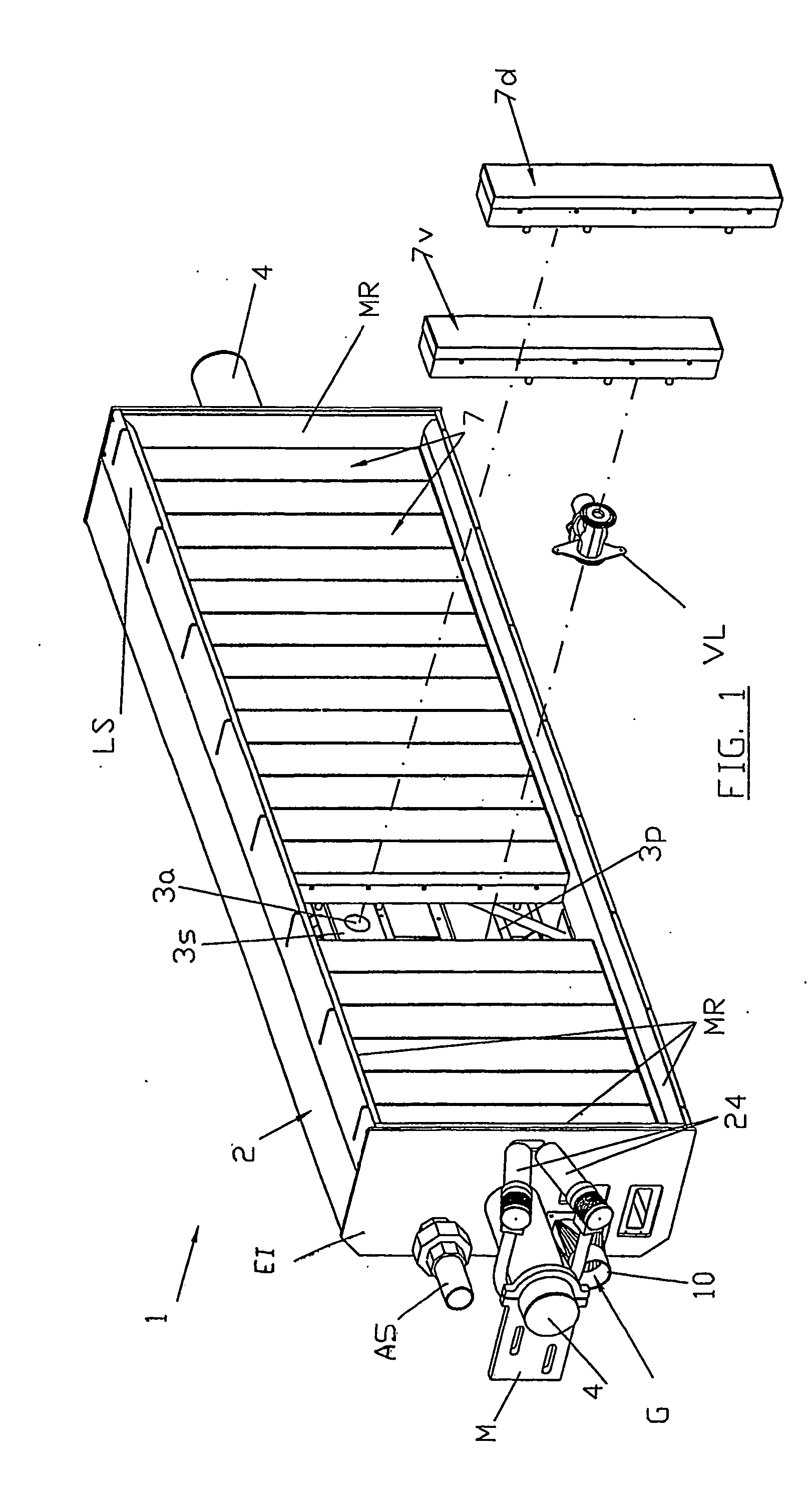

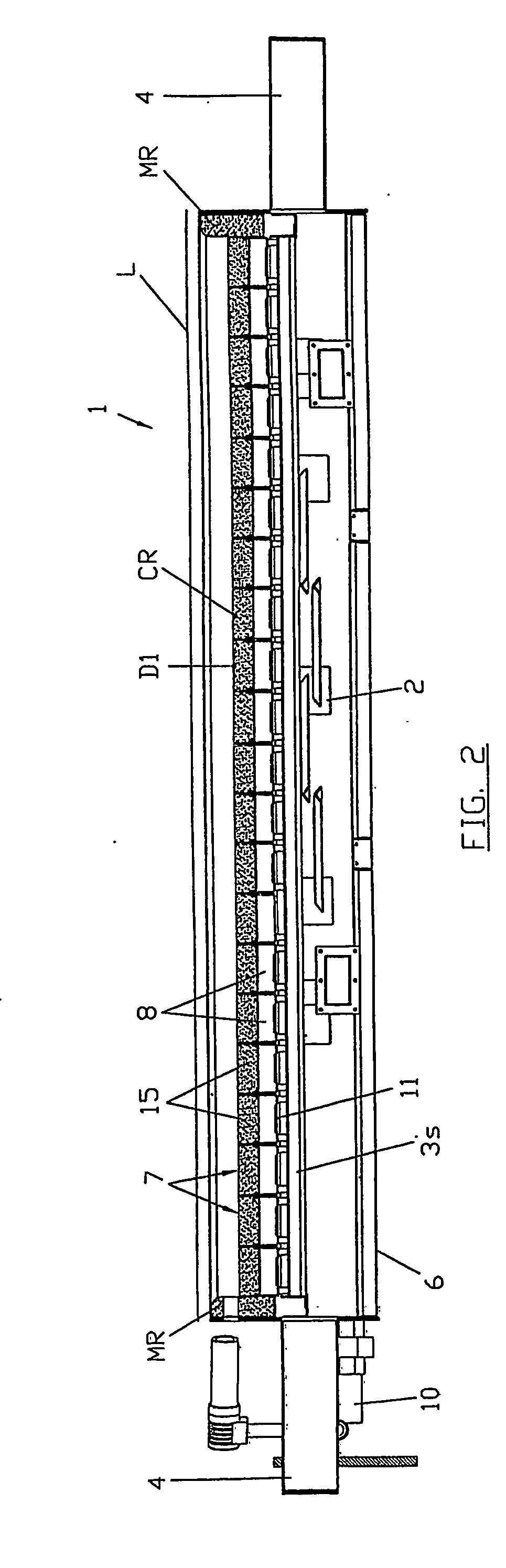

[0053] Referring to the Figures, the present invention refers to a MODULAR INFRARED IRRADIATION APPARATUS AND ITS CORRESPONDING MONITORING DEVICES, the modular heat irradiation apparatus (1) is directed to heat transfer operation involving elevated rates of heat to be contoinously traferred to a receiving substrate, e.g., industrial drying process of fibrous products as paper or cellulose (L) (FIG. 2).

[0054] According to the present invention and FIGS. 1 and 2, the modular heat irradiation apparatus basically comprises a metallic frame or bed (2) which is designed for receive a number of irradiation modules (7), according to process width and in such manner to receiver distribution and support ducts, priamary plenum (3p), secondary plenum (3s) which possesses gas / ar (G) mixture feeding outlets (3a) to the modules (7).

[0055] The employment of two plena having rectangular shape (3p and 3s) serve as mechanic support fo the modules (7) in order to position them in such manner to permi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com