Evaporator designs for achieving high cooling performance at high superheats

a superheat and evaporator technology, applied in indirect heat exchangers, lighting and heating apparatus, laminated elements, etc., can solve the problems of reducing cooling capacity, limiting the use of one or the other fins or dimples throughout all of the tubes in an evaporator, and reducing cooling capacity, so as to improve heat exchange efficiency. , the effect of improving the thermal energy exchang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

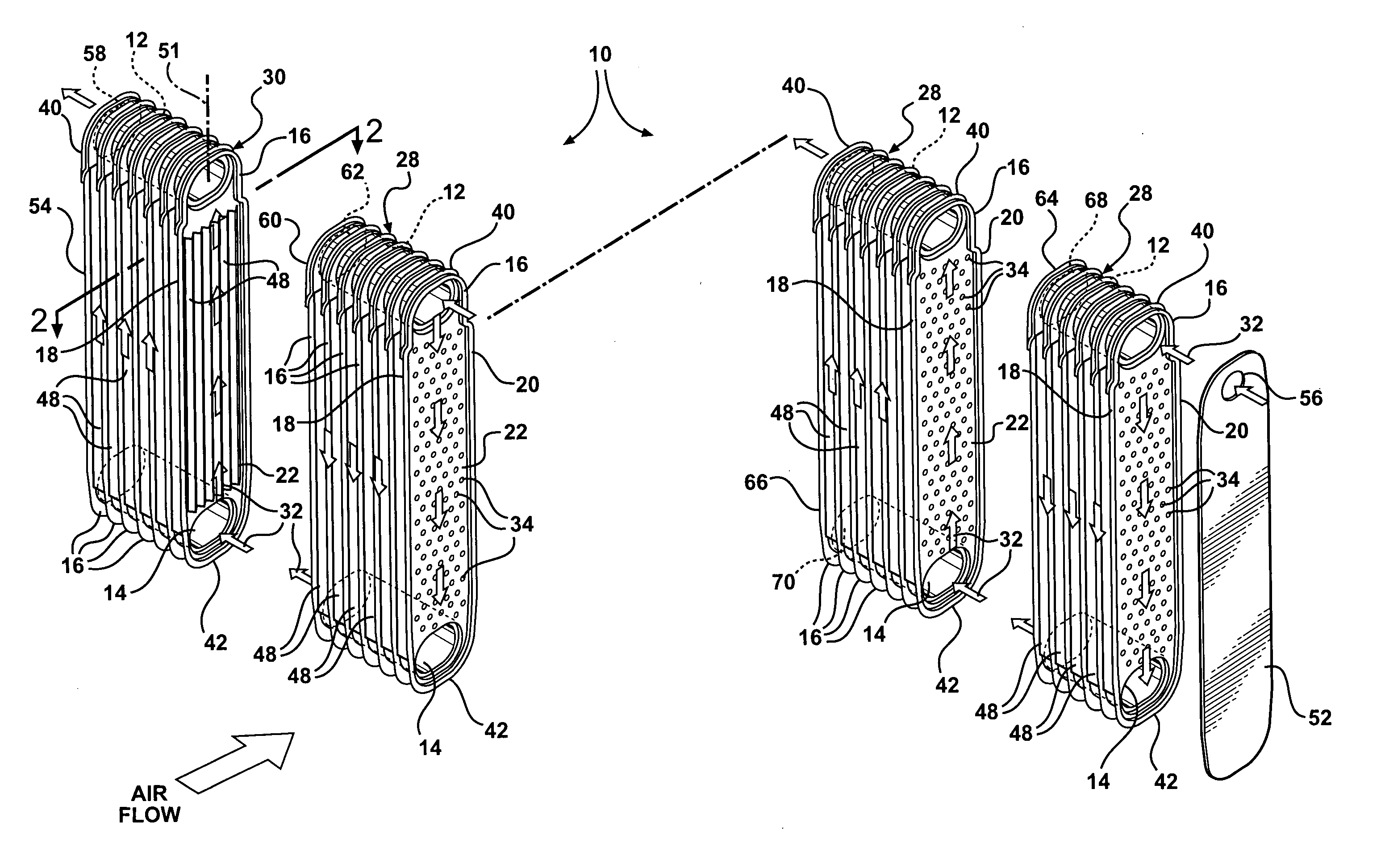

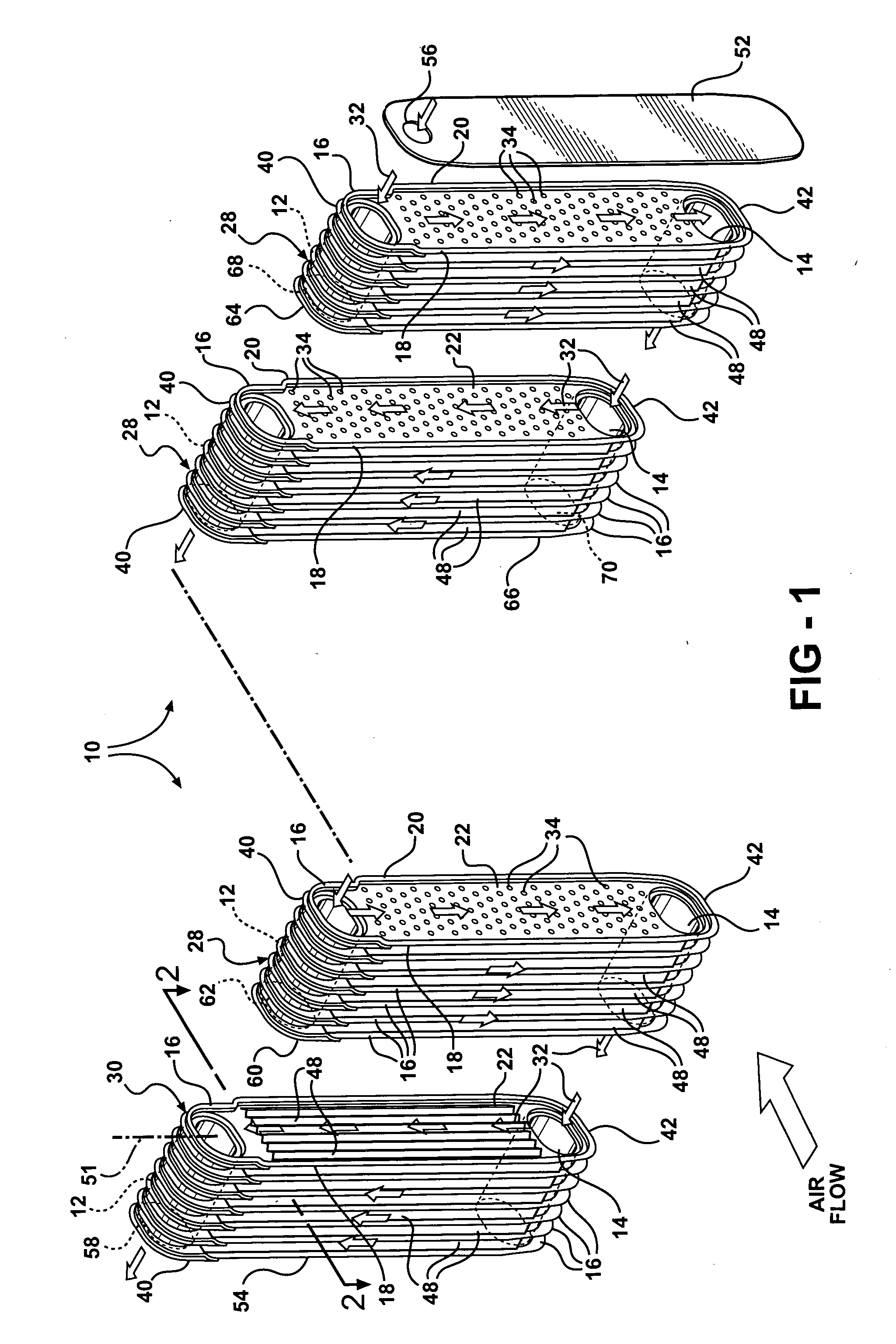

[0018] Referring now to the Figures, wherein like numerals indicate like or corresponding parts throughout the several views, a laminate-type evaporator is generally shown at 10 in FIGS. 1 through 3. The evaporator 10 includes upper and lower or first and second tanks 12, 14 and is fabricated from a plurality of plates 16.

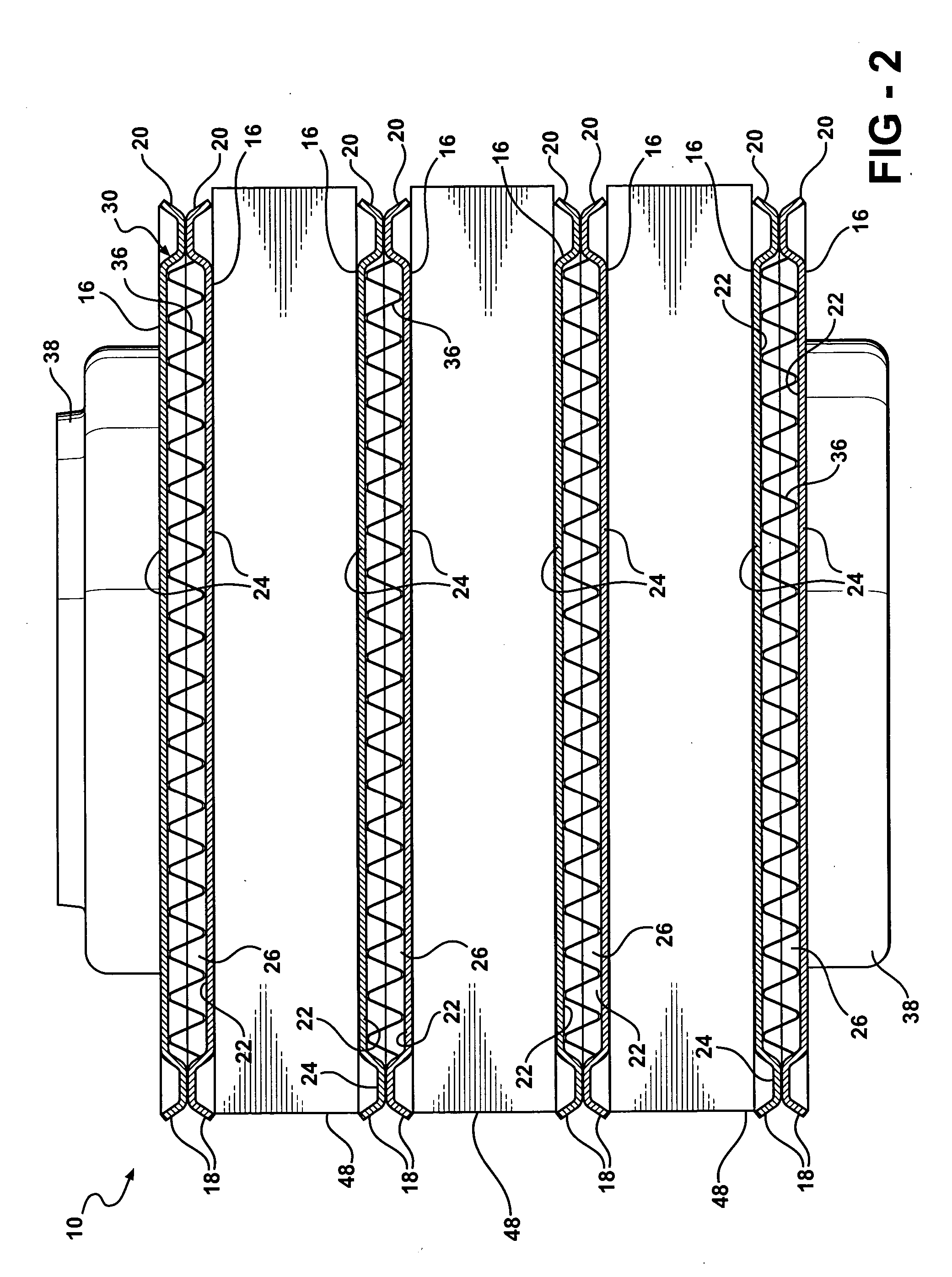

[0019] Each of the plates 16 has upstream and downstream side edges 18, 20 with an interior portion 22 recessed relative thereto. As shown in FIG. 2, the plates 16 are disposed in pairs 24, with the side edges 18 and 20 in overlapping and abutting engagement with one another such that the interior portions 22 define a passageway 26 between the plates 16 in each pair 24.

[0020] Referring now to FIG. 1, the pairs 24 are spaced along the tanks 12, 14 in first and second groups 28, 30 with the passageways 26 in fluid communication with the tanks 12, 14. The manner in which the passageways 26 are interconnected permits a fluid, or fluid stream of refrigerant, 32 to flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com