Linear sweeping magnetron sputtering cathode and scanning in-line system for arc-free reactive deposition and high target utilization

a magnetron sputtering cathode and scanning in-line system technology, applied in the field of sputtering, can solve problems such as non-uniform target erosion patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

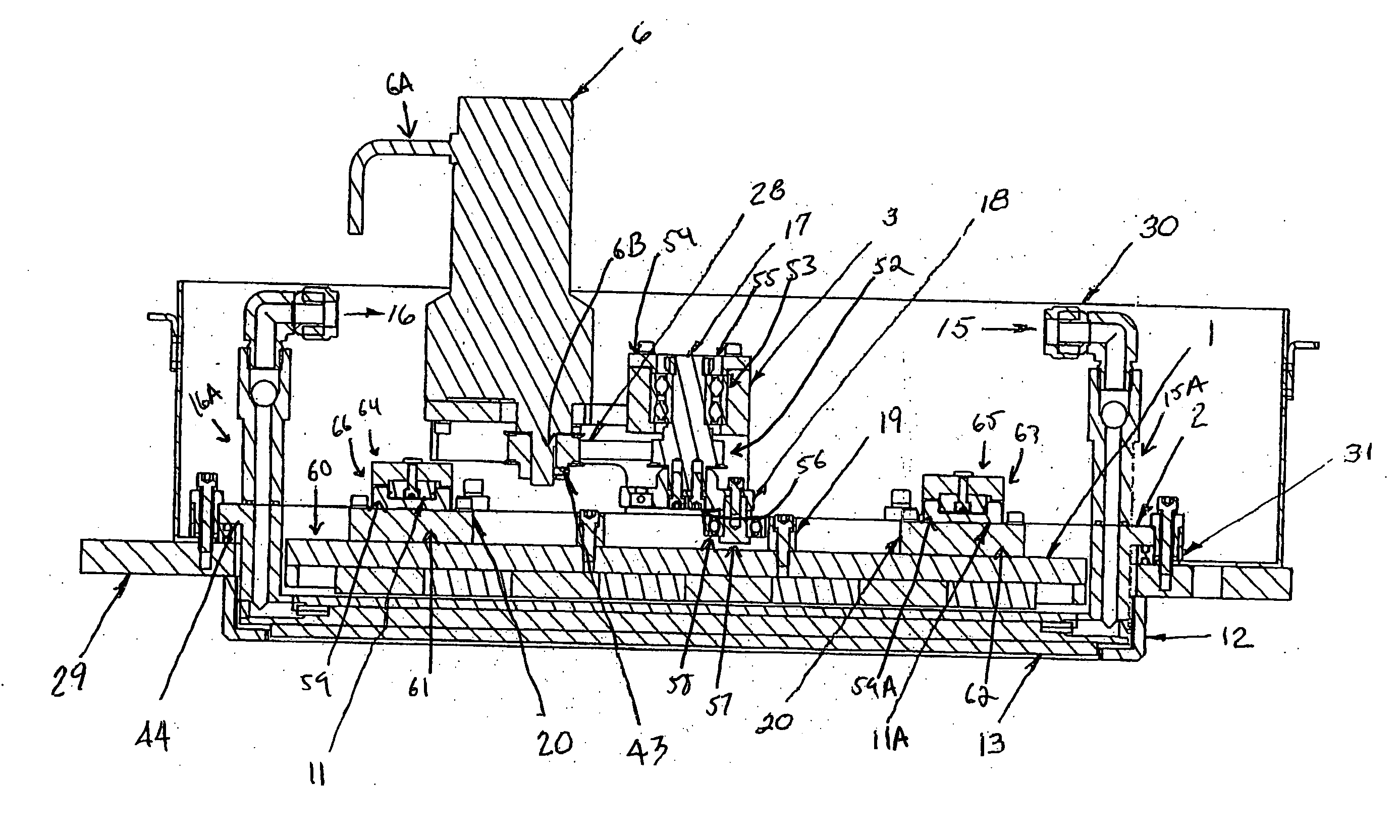

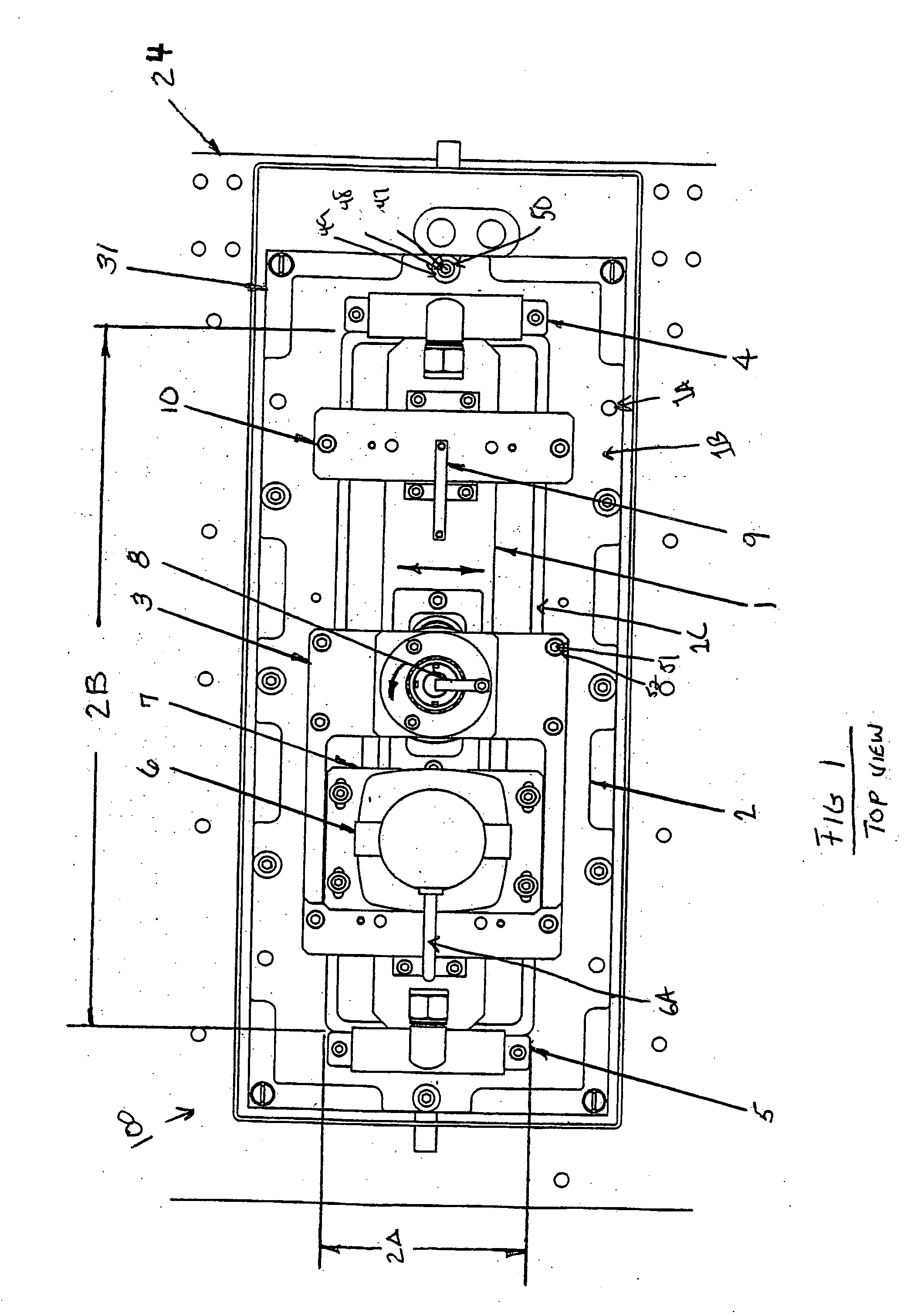

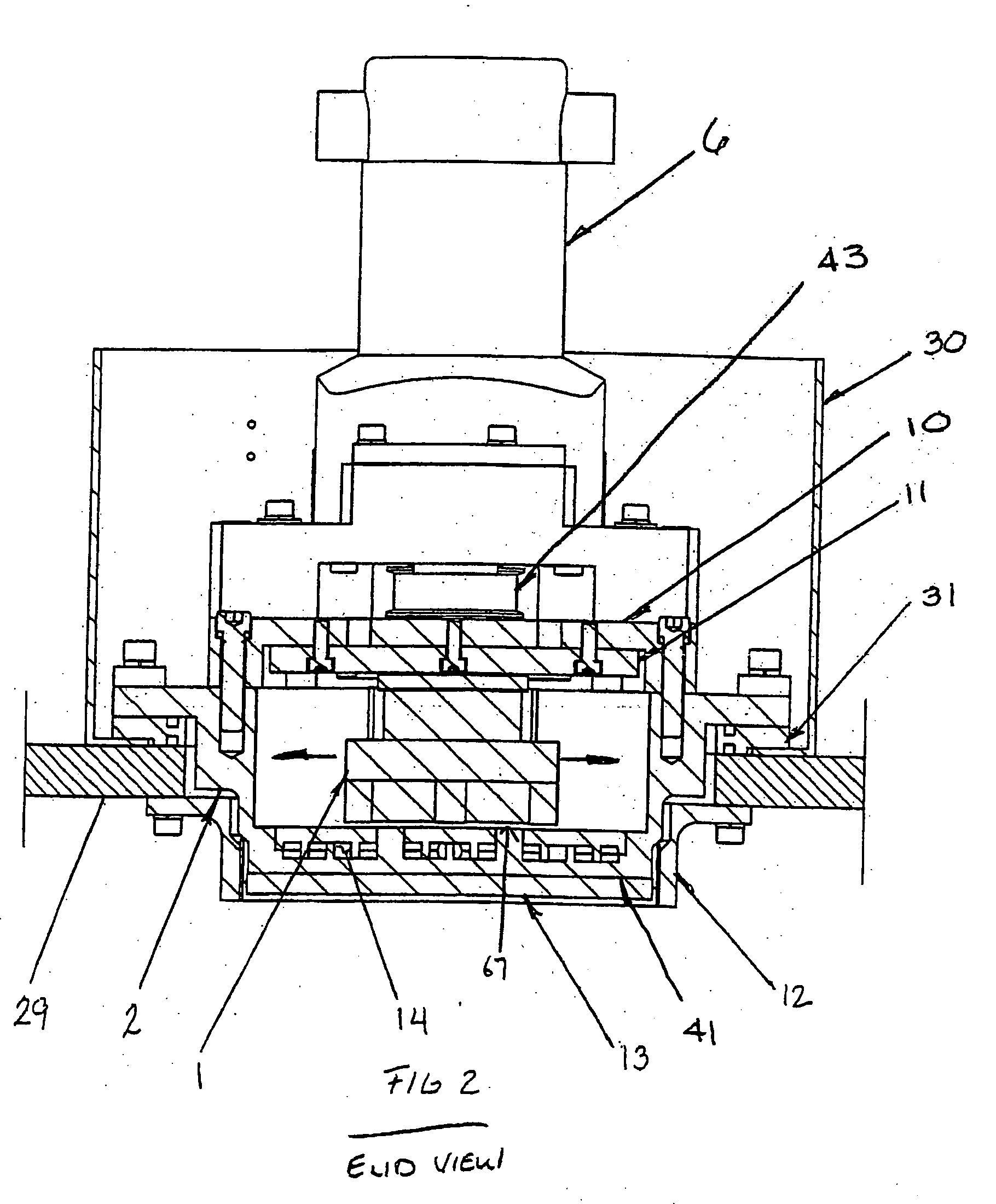

[0130] One embodiment of the present invention, an improved linear magnetron assembly for uniform target erosion, is depicted in FIG. 1. The linear magnetron 100 includes a cathode backing plate 2. The cathode backing plate 2 may be in the form of a copper plate, or manufactured from another suitable substance with similar electrical and thermal conductivity characteristics. Preferably, the cathode backing plate 2 may have terminals (not shown) for receiving an electric current. The linear magnetron assembly 100 should be adapted to be attached to a chamber top plate 29, which can be the top surface of a vacuum chamber 34 wherein the plasma deposition process will occur.

[0131] The cathode backing plate 2 may have a plurality of orifices 1A for receiving a bolt or other securing means positioned at various locations around the perimeter. These orifices around the cathode backing plate 2 are for securing the cathode backing plate 2 to a cathode insulator 31. Alternatively, the cathod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speeds | aaaaa | aaaaa |

| travel speed | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com