Hydraulic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

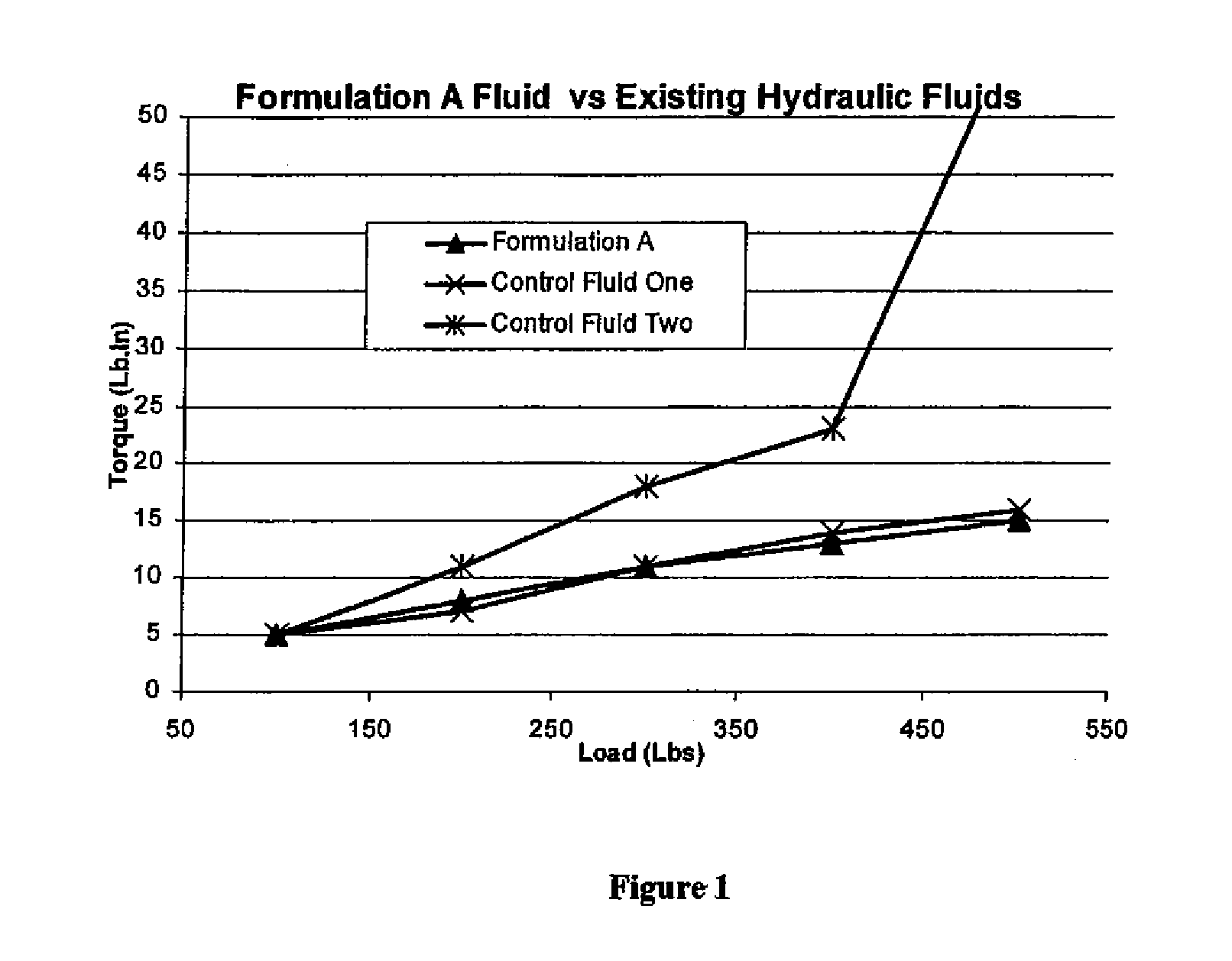

[0052] An aqueous hydraulic fluid of the invention (Formulation A) was prepared by mixing the following ingredients then homogenising this mixture under pressures of between 500-5,000 psi until a stable dispersion was achieved. The resultant product was then filtered to remove any large particles: [0053] 10% w / w Soybean Lecithin, supplied by Cargill PLC, UK [0054] 0.1% w / w Benzotriazole, supplied by Ellis and Everard PLC (UNIVAR), UK [0055] 0.1% w / w EDTA, supplied by BASF PLC, UK [0056] 10% Decanoic Acid(supplied by Multisol, UK) / TEA (supplied by Univar, UK), pre-neutralised salt to pH 8.8 [0057] 5% w / w Triazene, supplied by Thor Chemicals, UK [0058] 40% w / w Monoethylene Glycol, supplied by Ellis & Everard PLC, (Univar), UK [0059] Water to balance

[0060] This formulation, hereinafter referred to as Formulation A, is utilised as a BOP hydraulic fluid concentrate that is diluted by the consumer prior to use, typically to a working concentration of 20% v / v in water and antifreeze mix, ...

example 2

[0074] A second preferred embodiment of the aqueous hydraulic fluid of the invention, Formulation B, was prepared by mixing the following ingredients then homogenising this mixture under pressures of between 500-5,000 psi until a stable dispersion was achieved. Resultant product was then filtered to remove any large particles: [0075] 2% w / w Soybean Lecithin [0076] 0.01% w / w Benzotriazole [0077] 0.01% w / w EDTA [0078] 0.5% Decanoic Acid / TEA, pre-neutralised salt to pH 8.8 [0079] 0.3% w / w Triazene [0080] 40% w / w Monoethylene Glycol [0081] Water to balance

[0082] The above mentioned formulation is hereinafter called Formulation B.

[0083] Formulation B was subjected to the Falex Lupricity Test as described above, and exhibited similar performance to Formulation A. The results showed that Formulation B provided effective water based hydraulic fluid for the off-shore and mining fields.

[0084] The aqueous hydrocarbon fluid of the invention exhibit excellent environmental characteristics, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com