Method and device for measuring the power dissipated by a hydridation reaction in tubes and tubular claddings and the corresponding variation in electric resistance

a technology of hydridation reaction and power dissipation, which is applied in the field of methods and devices, can solve problems such as catastrophic fracture, and achieve the effects of preventing unplanned shutdown of commercial reactors, reducing the risk of hydration reaction, and ensuring the safety of the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples of embodiment

OF THE INVENTION

Example 1

Measurement of the Hydridation Kinetics in Tubes or Tubular Claddings

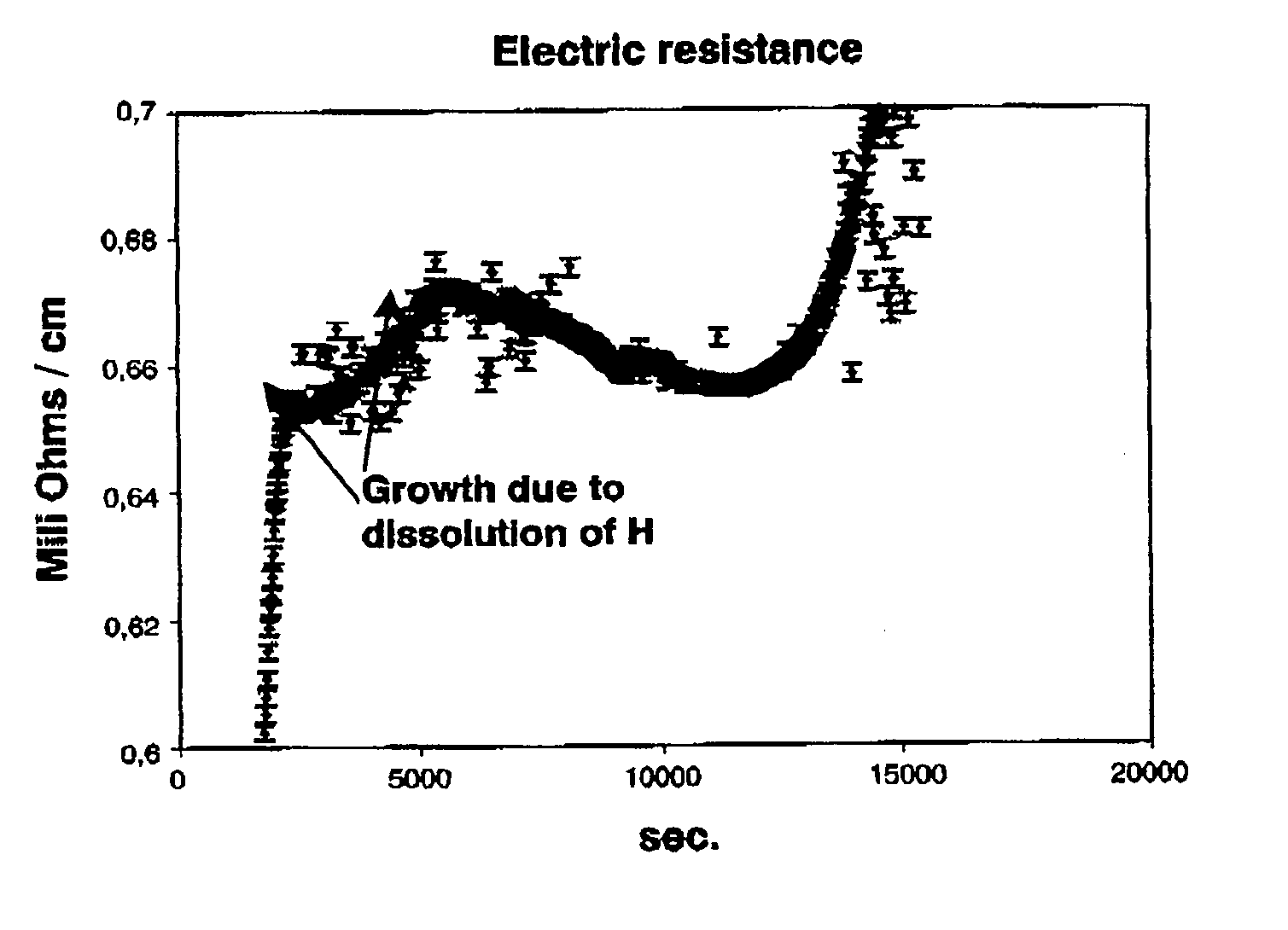

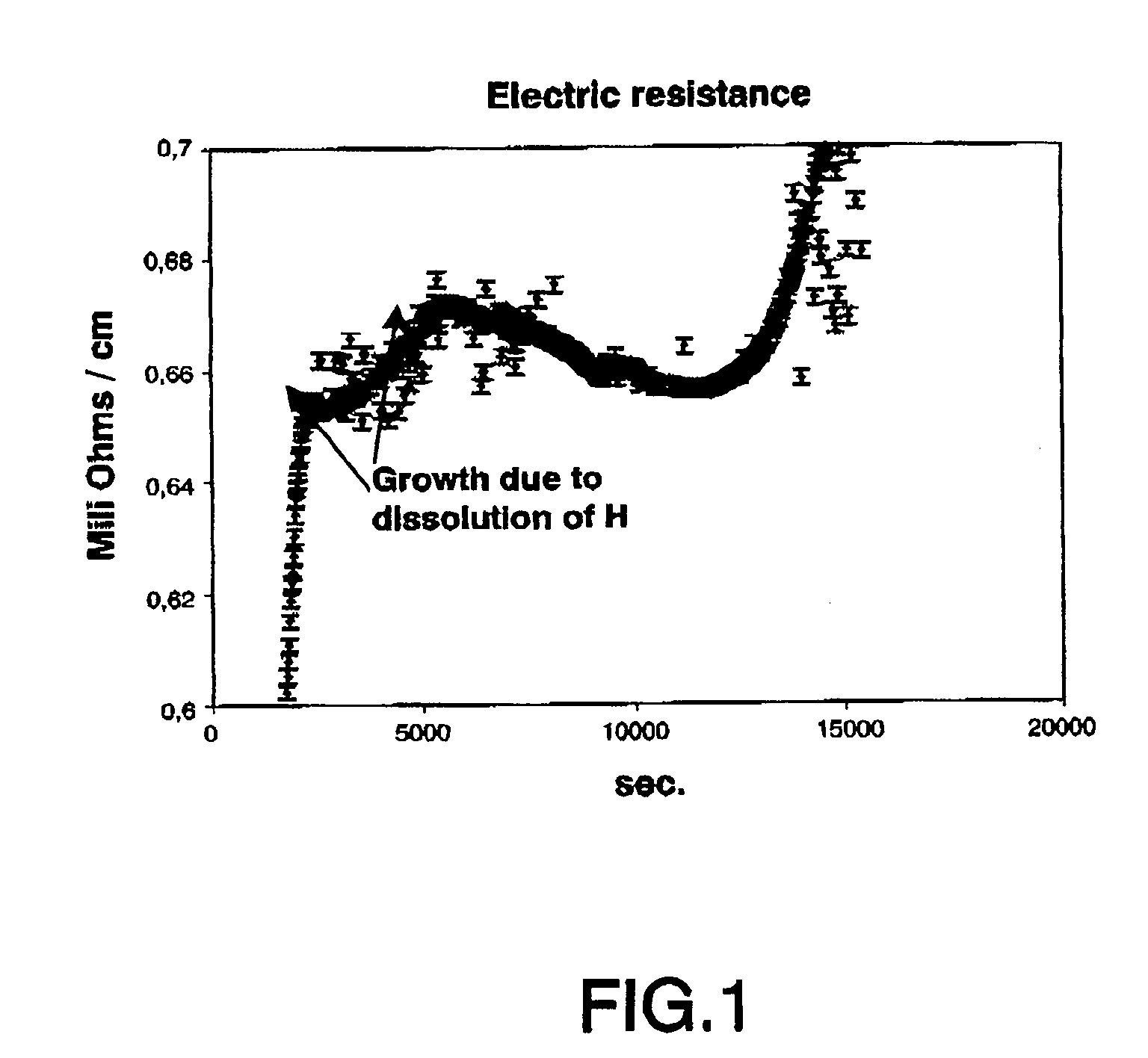

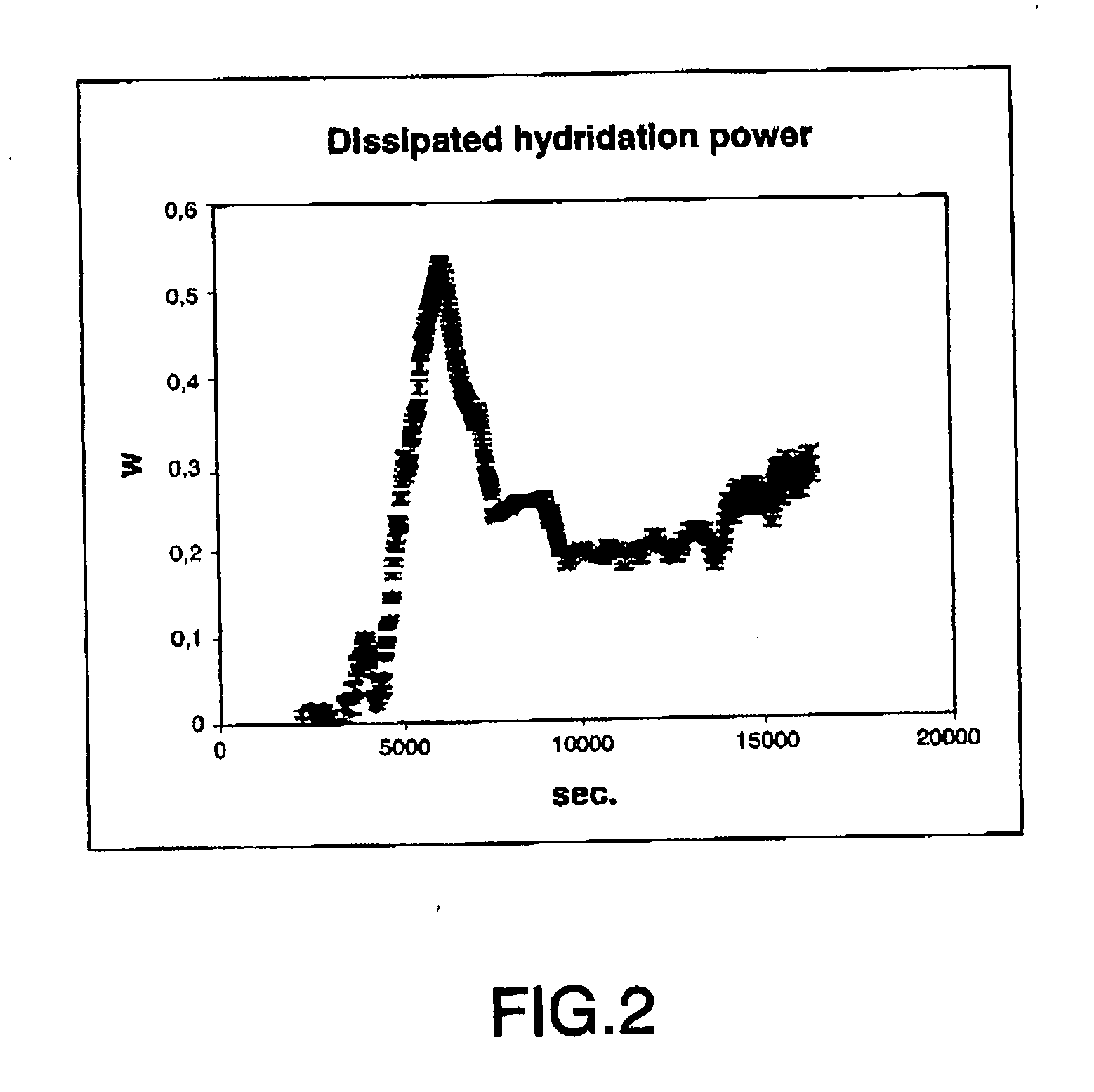

[0037] A method for measuring the dissipated power and the electric resistance and thereby obtain the hydridation kinetics in tubes or tubular claddings is embodied as stated below.

[0038] A nuclear fuel cladding of Zircaloy 2 is inserted in a high or ultra-high vacuum chamber; hydrogen or mixtures of hydrogen with other gas(es) is made to circulate via the interior of the tube at a pressure of 1 atmosphere and a renewal stream of 200 cm3 per minute. The partial pressure in the vacuum zone is 10−9 Torr owing to the permeation of hydrogen through the walls of the cladding. The cladding is heated by the Joule effect and the temperature in the centre of the cladding is monitored and kept constant at 360° C. (or other pre-established value) with a thermocouple and a temperature control system which acts on the current being applied in order to heat the cladding, the amount of current needed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| partial pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com