Olefin production via oxygenate conversion

a technology of oxygenate and olefins, applied in the field of olefin production, can solve the problems of general failure to provide processing schemes and arrangements, and achieve the effect of improving processing schemes and arrangements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

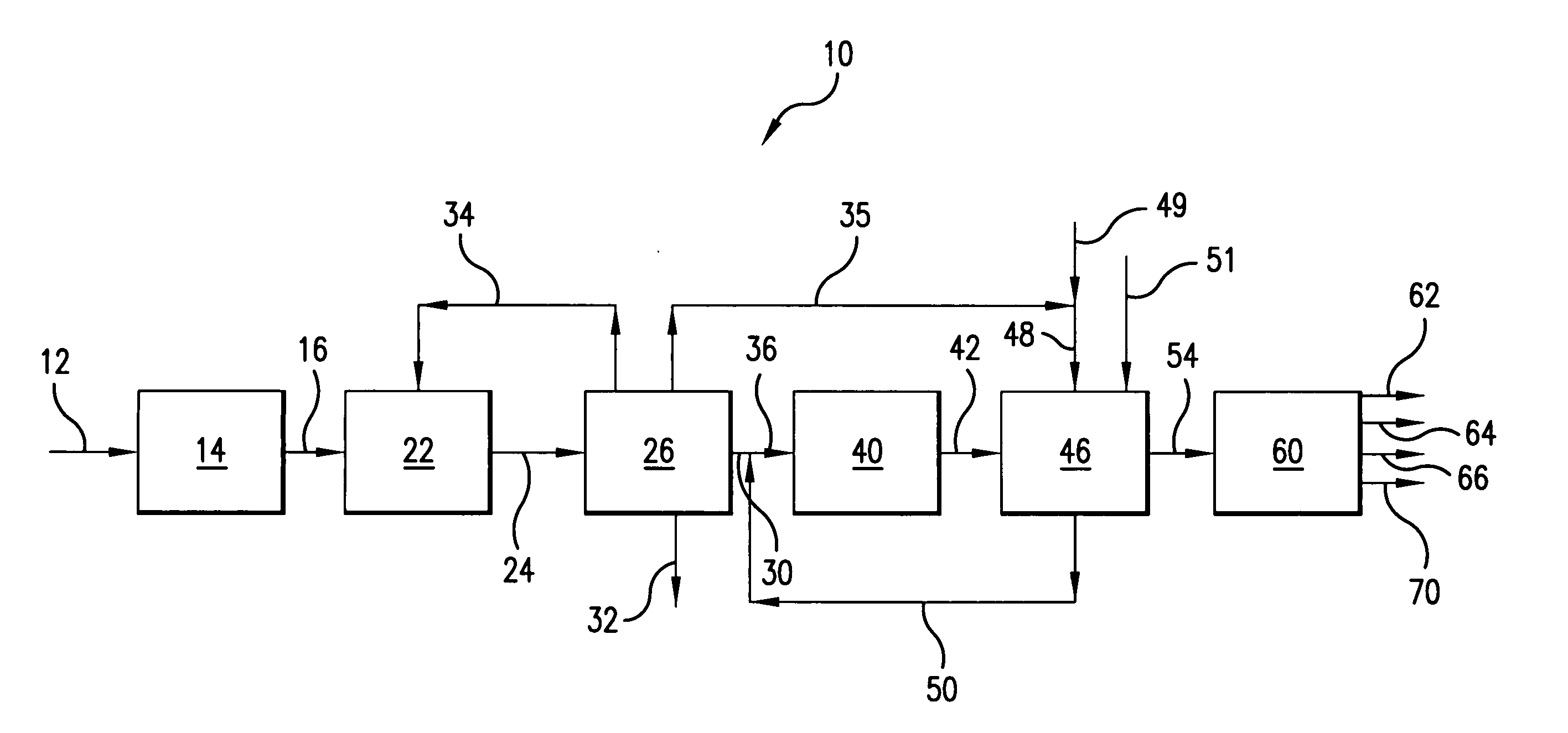

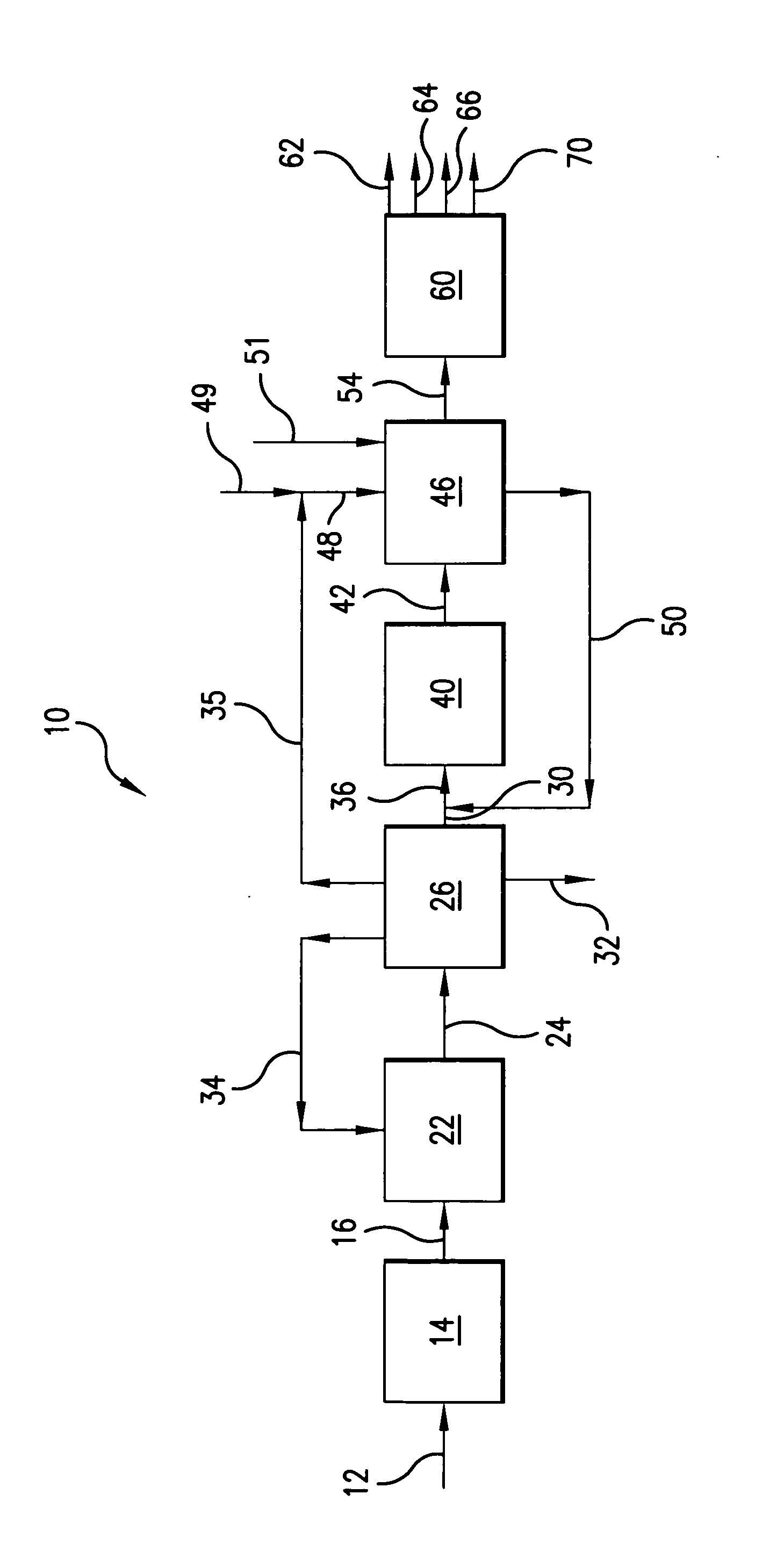

[0019] Referring to the FIGURE, there is illustrated a simplified schematic process flow diagram for a process scheme, generally designated by the reference numeral 10, for the production of olefins, particularly light olefins, via oxygenate conversion processing. It is to be understood that no unnecessary limitation to the scope of the claims which follow is intended by the following description. Those skilled in the art and guided by the teachings herein provided will recognize and appreciate that the illustrated process flow diagram has been simplified by the elimination of various usual or customary pieces of process equipment including some heat exchangers, process control systems, pumps, fractionation systems, and the like. It may also be discerned that the process flow depicted in the FIGURE may be modified in many aspects without departing from the basic overall concept of the invention.

[0020] A hydrocarbon feed stream, such as in gaseous form and designated by the referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com