Reducing nitrogen concentration with in-situ steam generation

a technology of in-situ steam generation and nitrogen concentration, which is applied in the direction of basic electric elements, electrical apparatus, semiconductor devices, etc., can solve the problems of reducing the performance of transistors, reducing the nitrogen concentration, and slowing down the oxidation process, so as to achieve enhanced nitrogen removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments described in this section illustrate but do not limit the invention. The invention is defined by the appended claims.

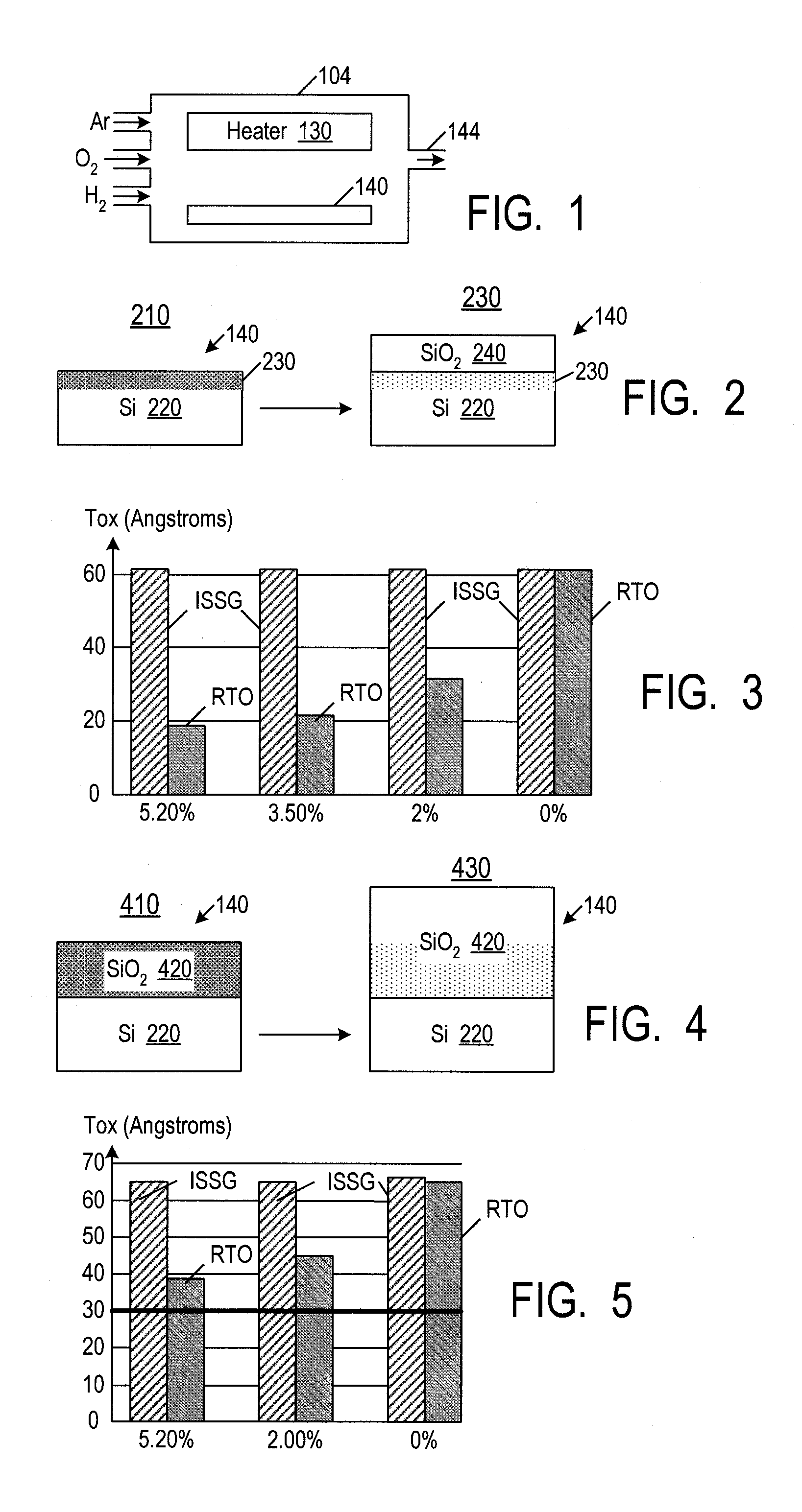

[0017]FIG. 1 illustrates a conventional ISSG chamber 104, such as described in U.S. patent application published as no. 2002 / 0146914 A1 on Oct. 10, 2002, filed by Huang et al., incorporated herein by reference. A silicon wafer 110 is placed in the chamber heated by a heater 130. Hydrogen, oxygen, and possibly other gases (e.g. argon or helium) are flown into the chamber. Hydrogen reacts with oxygen to form water vapor, i.e. H2O. The water vapor oxidizes silicon to form silicon dioxide (SiO2) and hydrogen. The gaseous by-products are pumped out via an exhaust path 144.

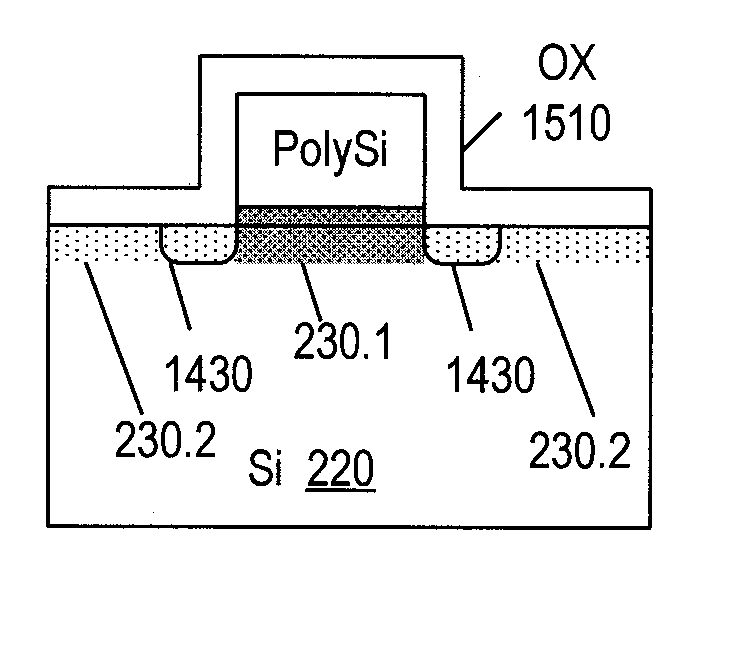

[0018] In FIG. 2, reference number 210 marks the silicon wafer 140 before the ISSG processing. The wafer contains a silicon substrate 220 (possibly, but not necessarily, monocrystalline silicon). The top region 230 of substrate 220 contains possibly unbound nitrogen atoms. Number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com