Method for determining an edge profile of a volume of a photoresist after a development process

a technology of photoresist and volume, applied in the field of method for determining can solve the problems of limited practical application of conventional simulation methods in order to predict the edge profile of a volume of a photoresist after a development process, and the general requirements of high computing time of conventional simulation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention described in the following are suited for determining an edge profile of a volume of a chemically amplified photoresist after a development process. Starting point of an inventive method typically is a volume of a photoresist which was subjected to a post exposure bake preceding the development process. Thereby it is assumed that a fraction of polymer sites of polymers of the photoresist are blocked or protected by dissolution inhibitors. More precisely, this condition is only fulfilled in the case of a positive tone photoresist. As mentioned above, this way of understanding is also applied in the case of a negative tone photoresist, though lacking an exact physical or chemical characterization.

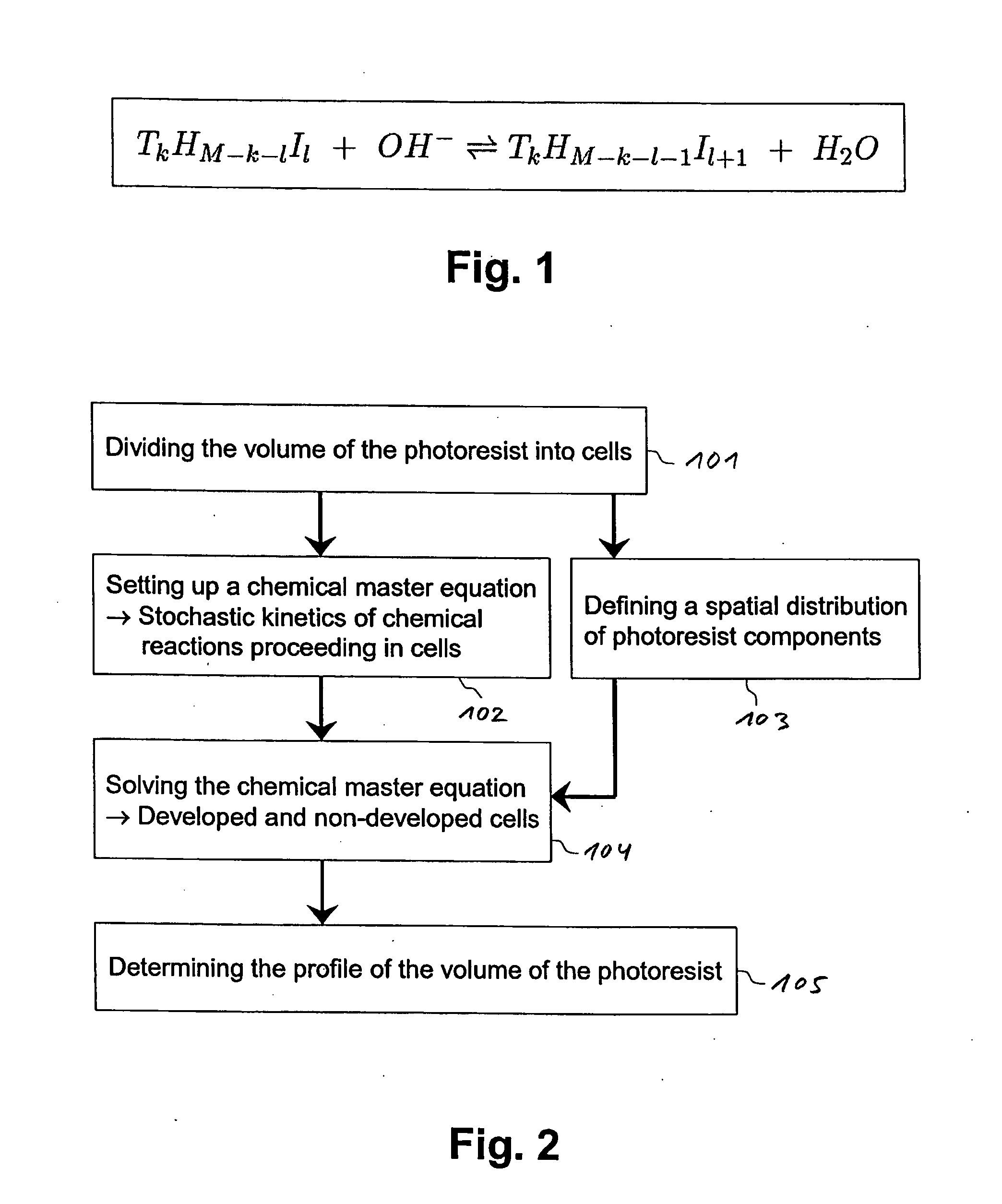

[0046]FIG. 1 shows a typical reaction scheme for a polymer of a photoresist during a development process illustrating a reversible ionization reaction between the polymer and components of a developer solution which is an aqueous base. The poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com