Laterally Implanted Electroabsorption Modulated Laser

a modulation laser and laser technology, applied in semiconductor lasers, instruments, non-linear optics, etc., can solve the problems of limited modulation efficiency, poor reliability and manufacturing complexity, and low output power, and achieve the effect of reducing the capacitance of the modulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

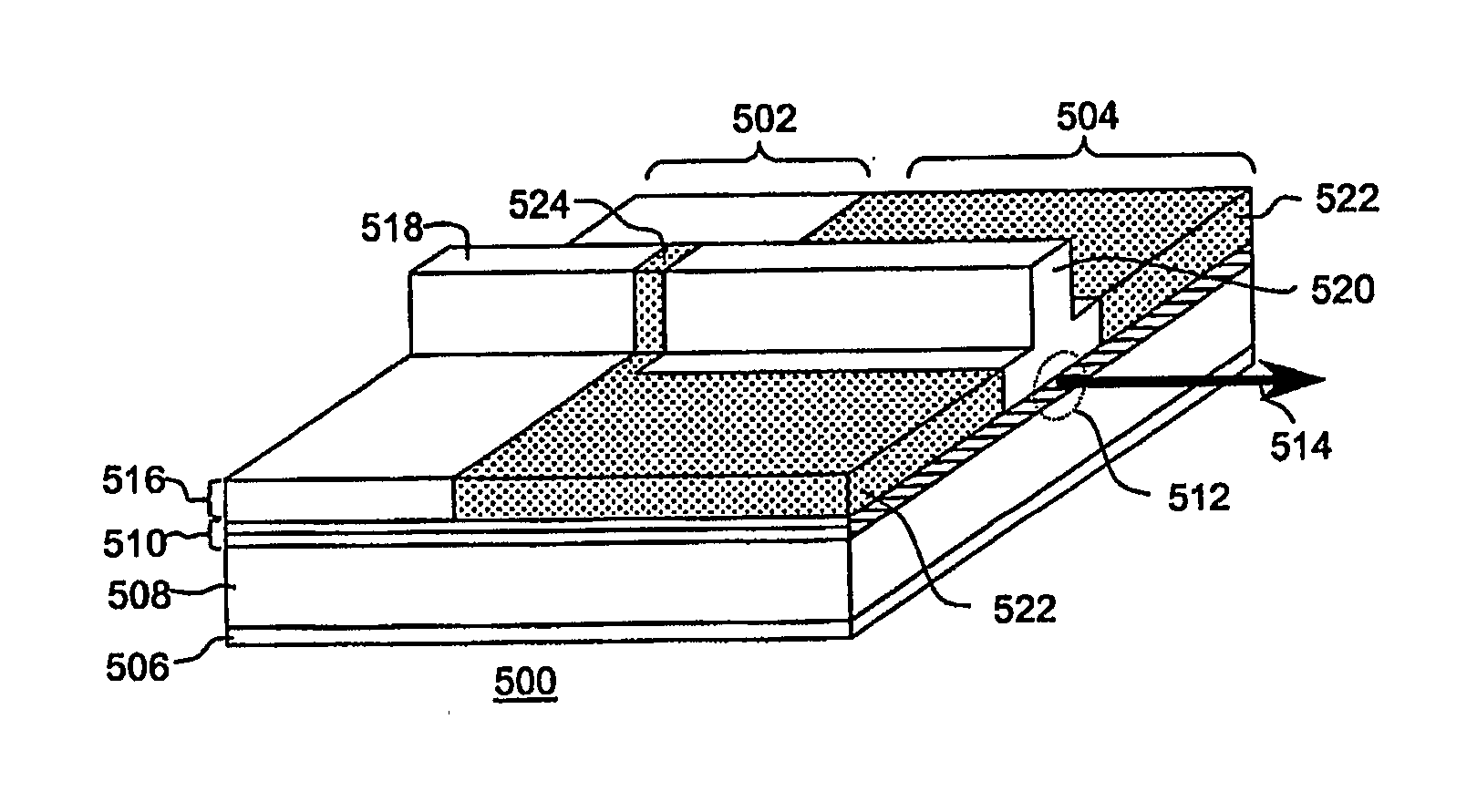

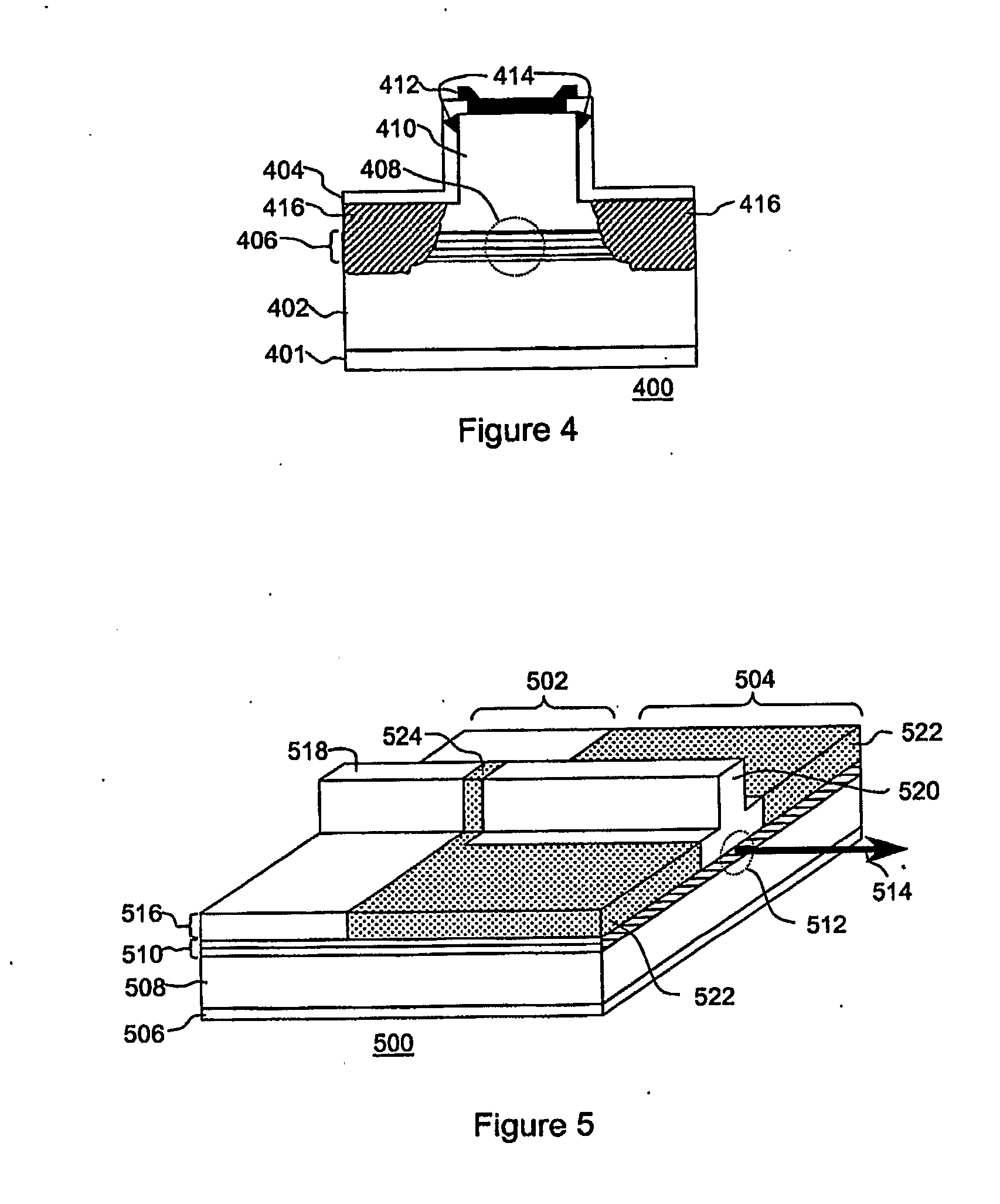

[0057] Generally, the present invention provides a monolithically integrated electroabsorption modulated laser wherein the modulator is of shallow etched ridge waveguide design which uses ion implantation of the etched upper cladding layer to reduce capacitance of the modulator.

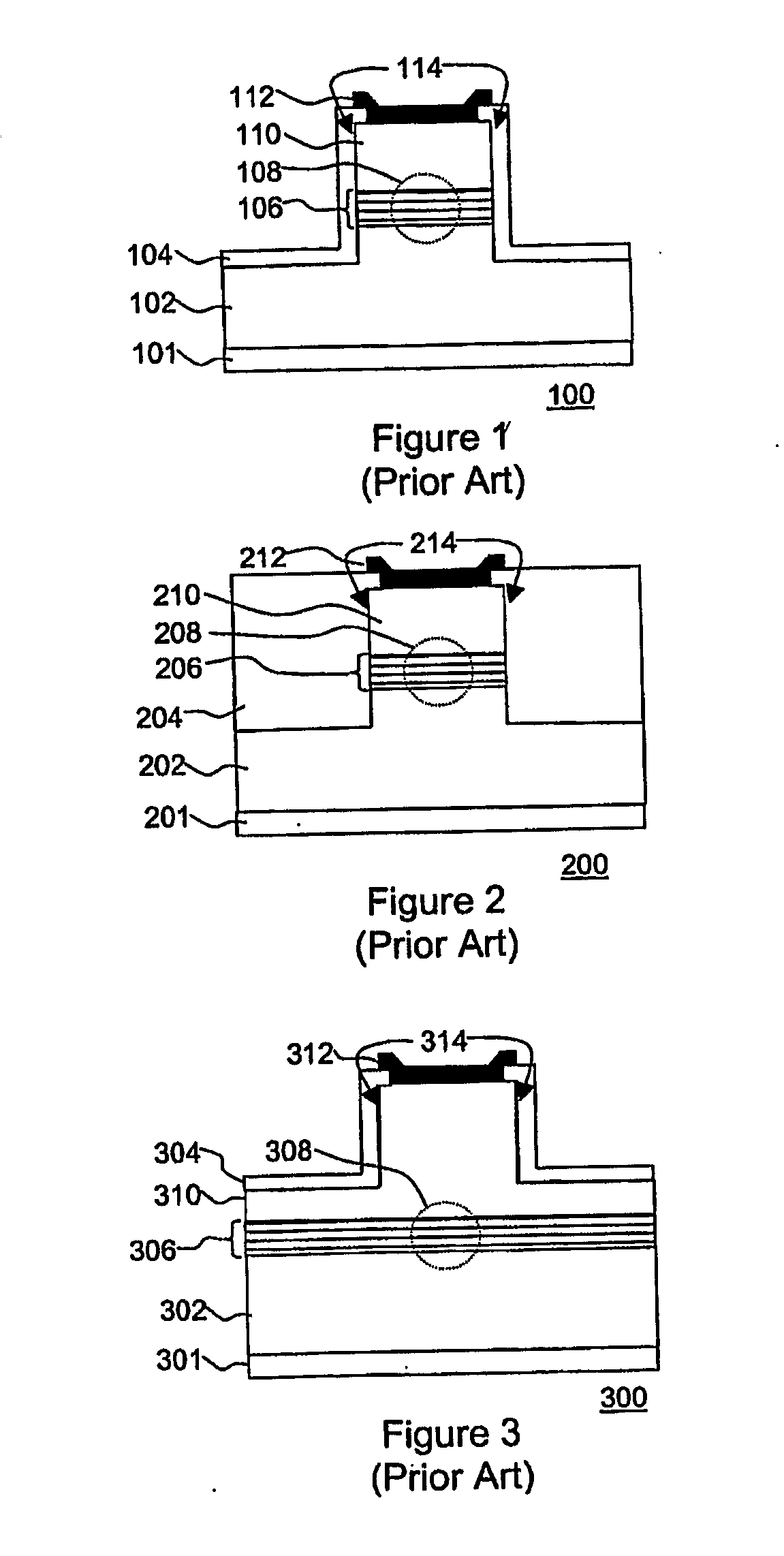

[0058]FIG. 1 is a simplified illustration of a prior art deeply etched optoelectronic device 100. FIG. 1 can represent a semiconductor laser or an electroabsorption modulator (EAM). A laser or an EAM are constructed of similar materials, but would differ in design details and operation. The device of FIG. 1 will now be described as an EAM 100. The EAM 100 is deeply etched. It comprises a semiconductor substrate 101, an active layer 106, followed by an upper cladding layer 110 and a metal electrode 112. The optical mode 108 is approximately centered around the active layer 106 which functions as a vertical waveguide. The horizontal waveguide function is provided by the deeply etched ridge of material bounded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| optical energy | aaaaa | aaaaa |

| epitaxial structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com