Semiconductor device and Manufacturing method thereof

a semiconductor device and semiconductor technology, applied in the direction of semiconductor devices, basic electric elements, electrical appliances, etc., can solve the problems of fear of a failure of the transistor, the inability to read (determine) stored data from the transistor, etc., to prevent a failure of the semiconductor device effectively, enhance yield, and enhance the electrical characteristic of the semiconductor device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

(Configuration Example 1 of Semiconductor Device)

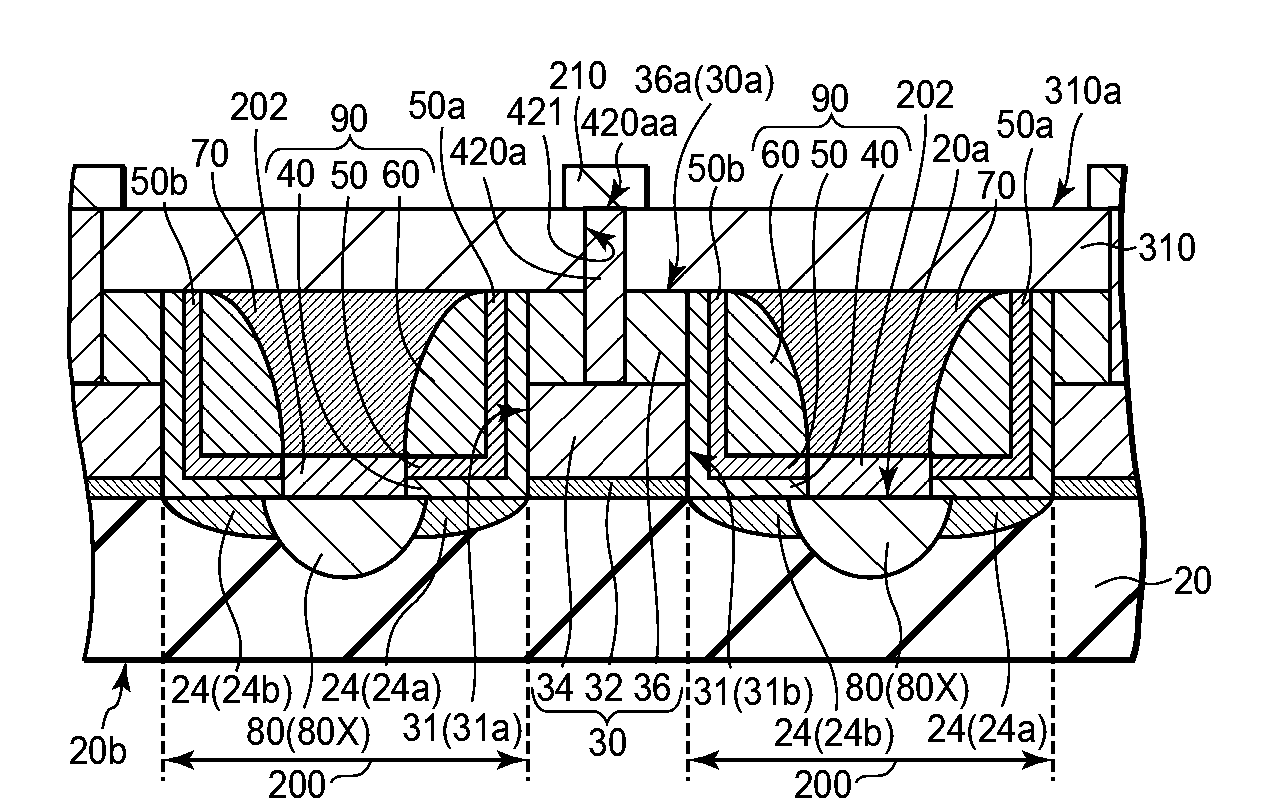

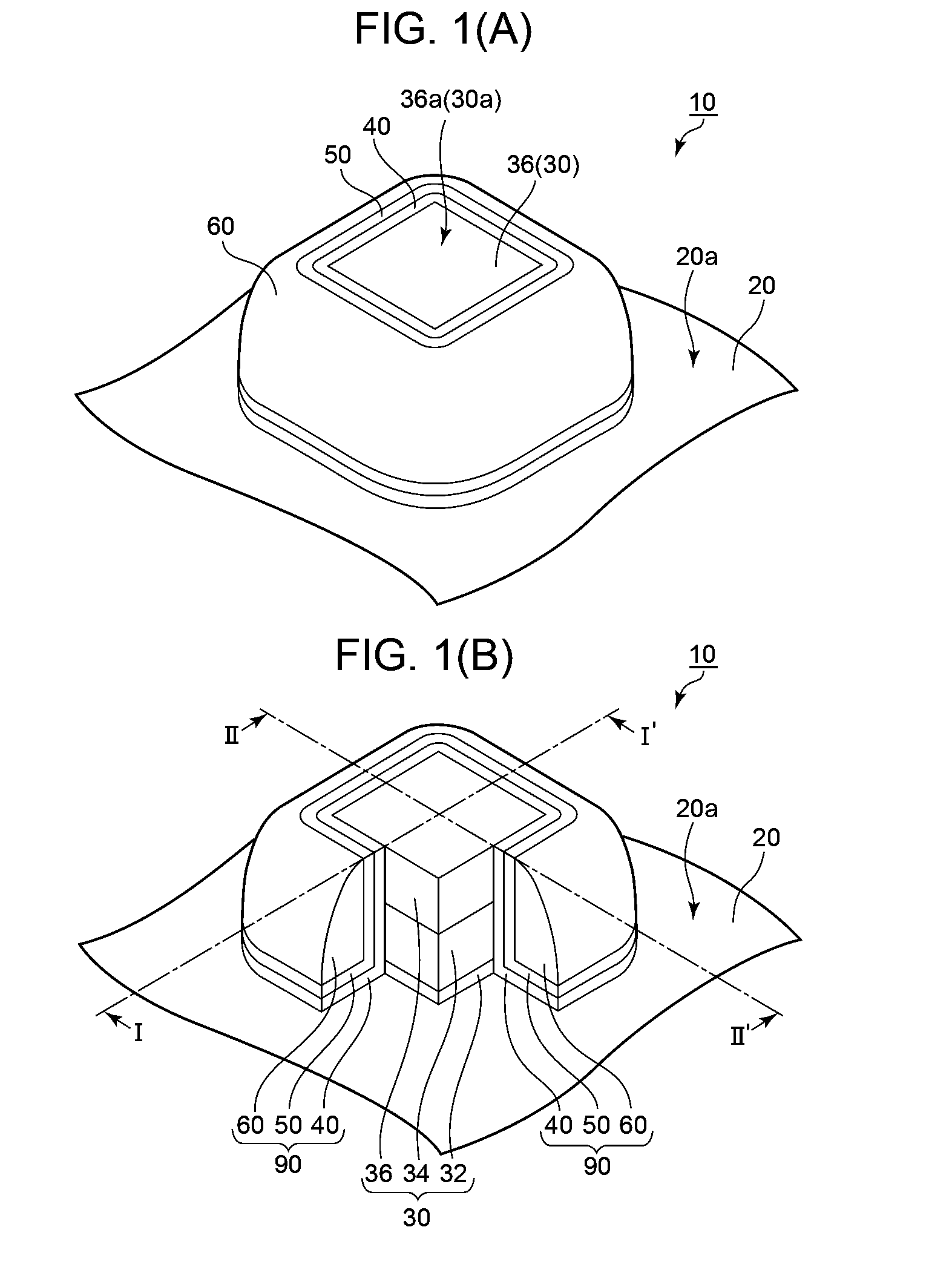

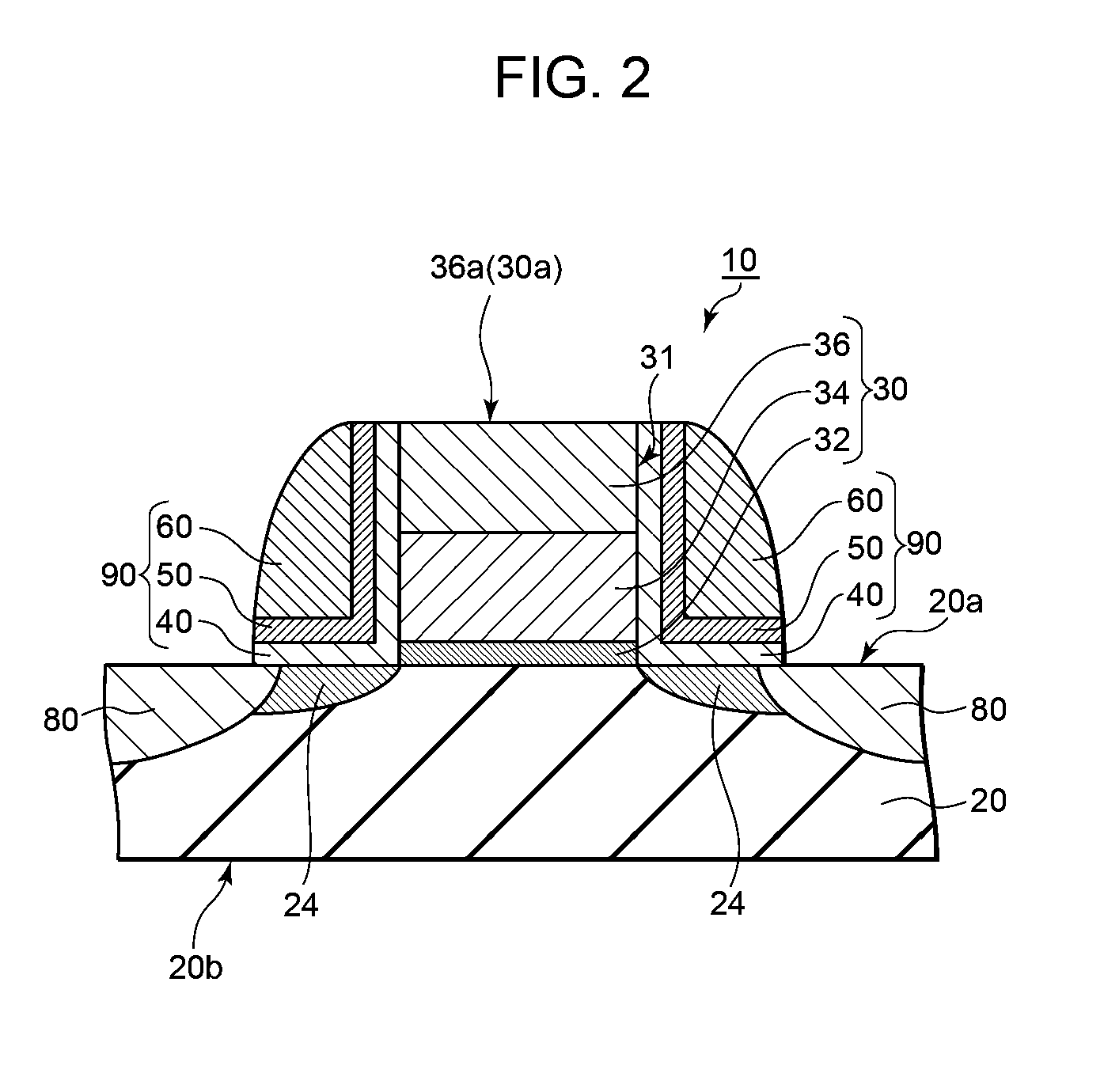

[0053]A configuration example of a semiconductor device (which also means a semiconductor element or chip, i.e., a transistor) of the present invention will be explained with reference to FIGS. 1, 2, 3 and 4. Incidentally, the semiconductor device of the present invention features configurations of a gate electrode and a sidewall.

[0054]FIGS. 1(A) and 1(B) are typical perspective views for describing an overall configuration of the semiconductor device of the present invention. FIG. 1(B) shows part of the semiconductor device in cut-away form to make it easy to understand the configurations of the gate electrode and sidewall.

[0055]FIG. 2 is a typical view showing a cut cross-section cut along one-dot chain line I-I′ shown in FIG. 1(B) or one-dot chain line II-II′ shown in FIG. 1(B).

[0056]FIGS. 3(A) and 3(B) are respectively typical perspective views for describing the configuration of the gate electrode.

[0057]FIG. 4(A) is a typical vie...

example 1

(Example 1 of Semiconductor Device Manufacturing Method)

[0101]An example of a method for manufacturing a semiconductor device of the present invention will be explained with reference to FIGS. 5, 6, 7 and 8.

[0102]FIGS. 5(A), 5(B) and 5(C) are respectively typical manufacturing process views for describing a process for manufacturing the semiconductor device of the present invention. FIG. 5(A) is a plan schematic view of the semiconductor device, FIG. 5(B) is a schematic view showing a cut cross-section cut along one-dot chain line III-III′ of FIG. 5(A), and FIG. 5(C) is a schematic view showing a cut cross-section cut along one-dot chain line IV-IV′ of FIG. 5(A).

[0103]FIGS. 6(A), 6(B) and 6(C) are respectively manufacturing process views following FIG. 5(C), showing cut cross-sections each cut at the same position as one-dot chain line IV-IV′ of FIG. 5(A).

[0104]FIG. 7 is a manufacturing process view following FIG. 6(C).

[0105]FIG. 8(A) is a manufacturing process view following FIG. 7...

second preferred embodiment

[0148](Configuration Example 2 of Semiconductor Device)

[0149]A configuration example of a semiconductor device of the present invention will be explained with reference to FIGS. 9(A) and 9(B). Incidentally, the semiconductor device of the present example has a feature in that the position of a gate electrode is shifted between adjacent sidewalls as compared with the first embodiment already described above.

[0150]FIG. 9(A) is a plan typical view of the semiconductor device as viewed from its upper surface side, and FIG. 9(B) is a typical view illustrating a cut cross-section cut along one-dot chain line V-V′ shown in FIG. 9(A).

[0151]As shown in FIGS. 9(A) and 9(B), the semiconductor device 10 includes a first conduction type substrate 20. In the present example, the first conduction type substrate 20 is of a P type substrate.

[0152]As shown in FIG. 9(B), the first conduction type substrate 20 has a front surface 20a and a back surface 20b opposite to the front surface 20a.

[0153]The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com