Golf Club Head and Its Process of Making

a golf club and head technology, applied in the field of golf club head making technology, can solve the problems of difficult acquisition of braze welding material, restricted mass production of golf clubs, unvaried structure formed by pressing, etc., and achieve the effect of strengthening the main body and the hitting face, reducing the coat and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0033]The steps of Embodiment 1 are as following:

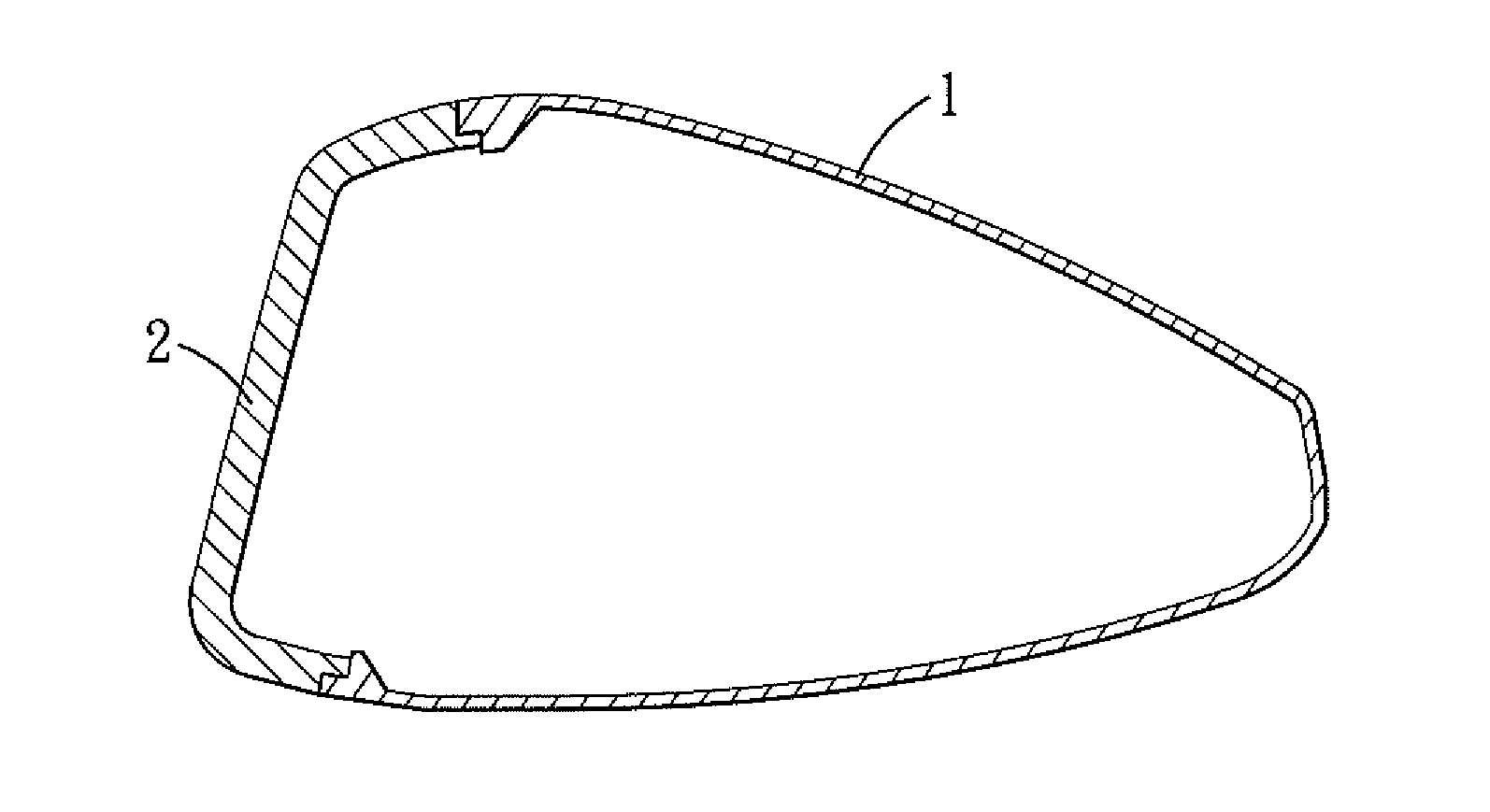

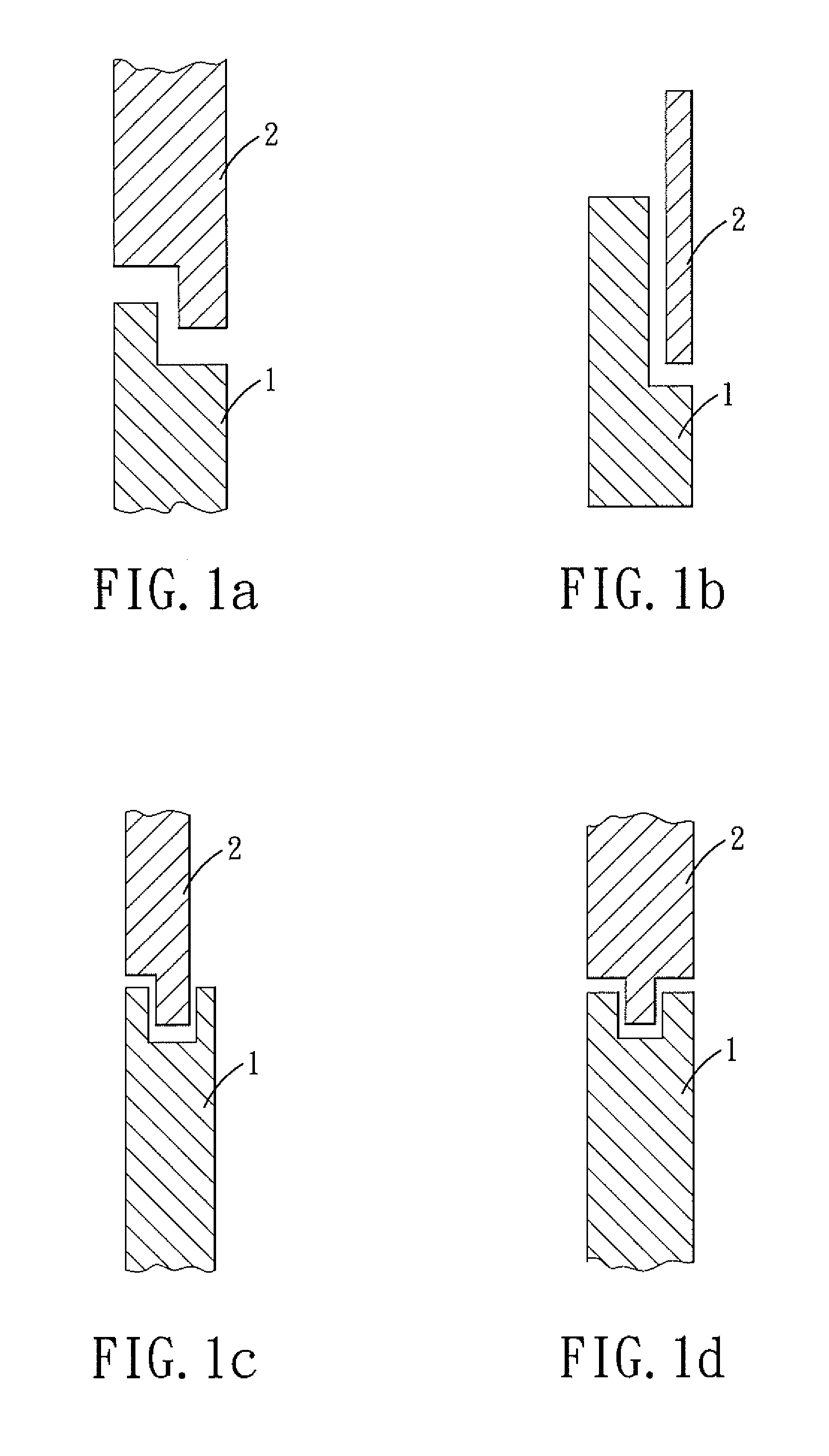

[0034]First, precisely molding a main body 1 with 17-4 stainless steel and a hitting face 2 with 6-4 Ti, the bonding surfaces of the main body 1 and the hitting face 2 being formed with a protruded section respectively that are relative to each other so as to form an L-shaped head, and the concave section engaging with the protruded section exactly (as shown in FIG. 1a);

[0035]Second, CNC processing cooperating with gap arithmetical ratio controlling +0.1 mm / −0 mm;

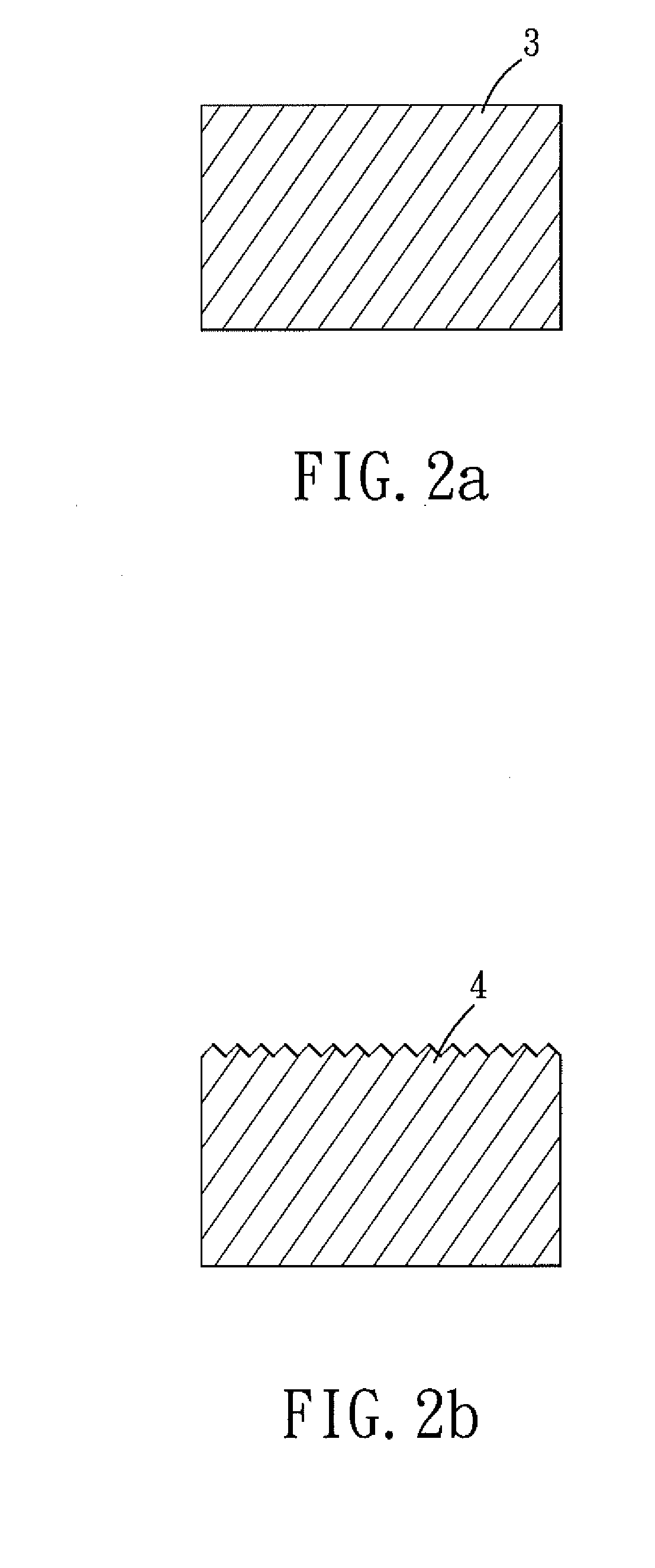

[0036]Third, surface treating by spraying each bonding face with AL2O3 so as to form micro concave and protruded portions, and the height of protruded portion being <0.3 mm;

[0037]Fourth, smearing the adhesive, whose shear strength is ≧25 Mpa, on the concave and protruded sections of the main body 1 and the hitting face 2, and then engaging the main body 1 with the hitting face 2 through the concave and protruded section;

[0038]Fifth, solidifying the adhesive through heating in...

embodiment 2

[0039]The steps of Embodiment 2 is as following:

[0040]First, precisely molding a main body 1, whose head is formed with a concave-shaped bonding surface, with 6-4TI, and forging a hitting face 2, whose head formed with a protruded-shaped bonding surface, with 6-4Ti; and the bonding surfaces engaging with each other exactly (as shown in FIG. 1d), the gap between the bonding surfaces being 1 of 6-4Ti being directly formed with micro concave and protruded portions, whose height is <0.3 mm, when being precisely molded;

[0041]Second, spraying the hitting face 2 of 6-4Ti with steel balls so as to form micro concave and protruded portions whose height is <0.3 mm;

[0042]Third, smearing the adhesive, whose shear strength is ≧25 Mpa, on the concave and protruded sections of the main body 1 and the hitting face 2, and then engaging the body 1 with the hitting face 2;

[0043]Fourth, solidifying the adhesive through heating in a oven for 40 minutes under the temperature of 140' C, thus the main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com