Water resistance, density, and durability of biomass fuels

a biomass fuel and density technology, applied in the direction of solid fuels, waste based fuels, petroleum industry, etc., can solve the problems of low density or uniformity of biomass fuels, commercial unworkability, and proponents of biomass fuels that have struggled to find ways to maximize, so as to increase density and durability, the effect of increasing density and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

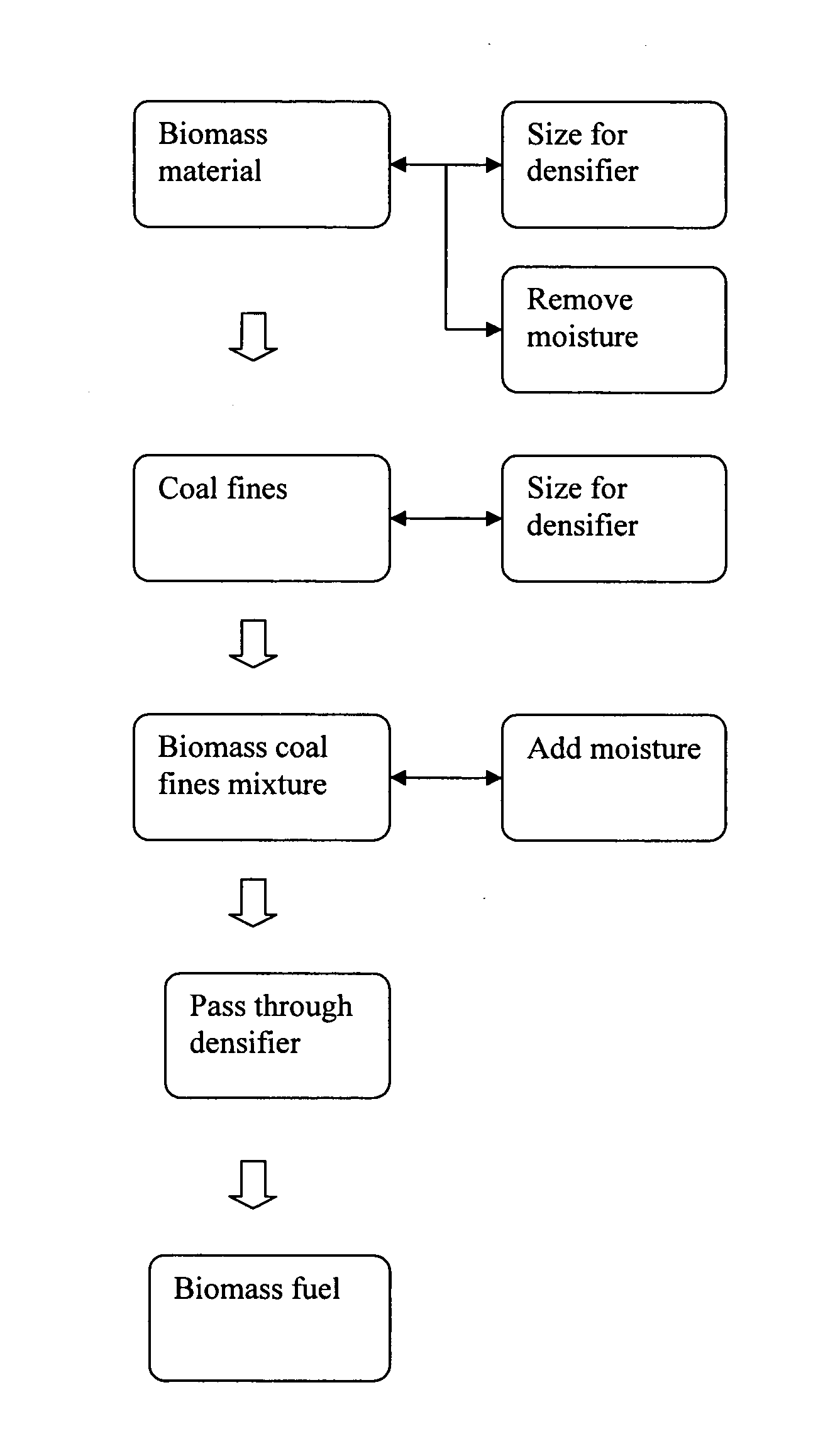

[0008] By carefully blending biomass fuels with coal fines prior to their introduction into a densification machine, the resulting biomass fuel product is resistant to water damage. In some cases, depending on the percentage of coal fines utilized, it is possible to obtain a resulting biomass fuel which is almost totally waterproof.

[0009] By using a blend of biomass and coal fines in biomass fuel production, the density and durability of the biomass fuel product is increased as compared to biomass fuel products which do not contain coal fines. It is believed that this increased density and durability is very important for the economics of transportation, handling, and the introduction of the fuel cube into a combustion system.

[0010] Mechanical processes for making biomass fuels are well known. The biomass material may be grass, grain, paper, animal wastes, wood waste, sewer sludge or other naturally occurring biological waste. A manufacturer may pass this biomass material through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| combustible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com