Method of determining laser stabilities of optical materials, crystals selected according to said method, and uses of said selected crystals

a technology of optical materials and laser stability, which is applied in the direction of material analysis, instruments, spectrum investigation, etc., can solve the problems of loss of optical quality, change in imaging behavior, and change of lens geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

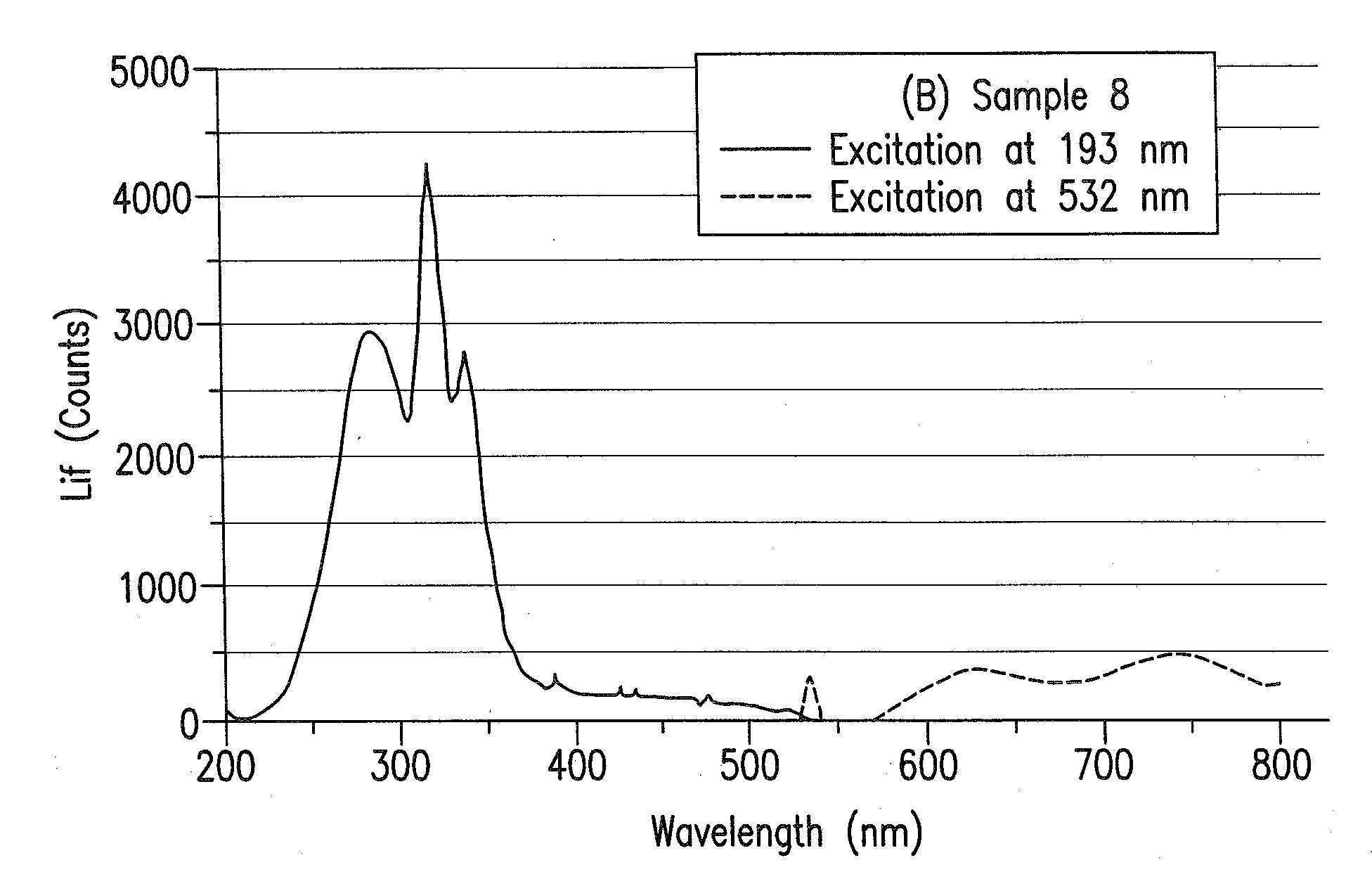

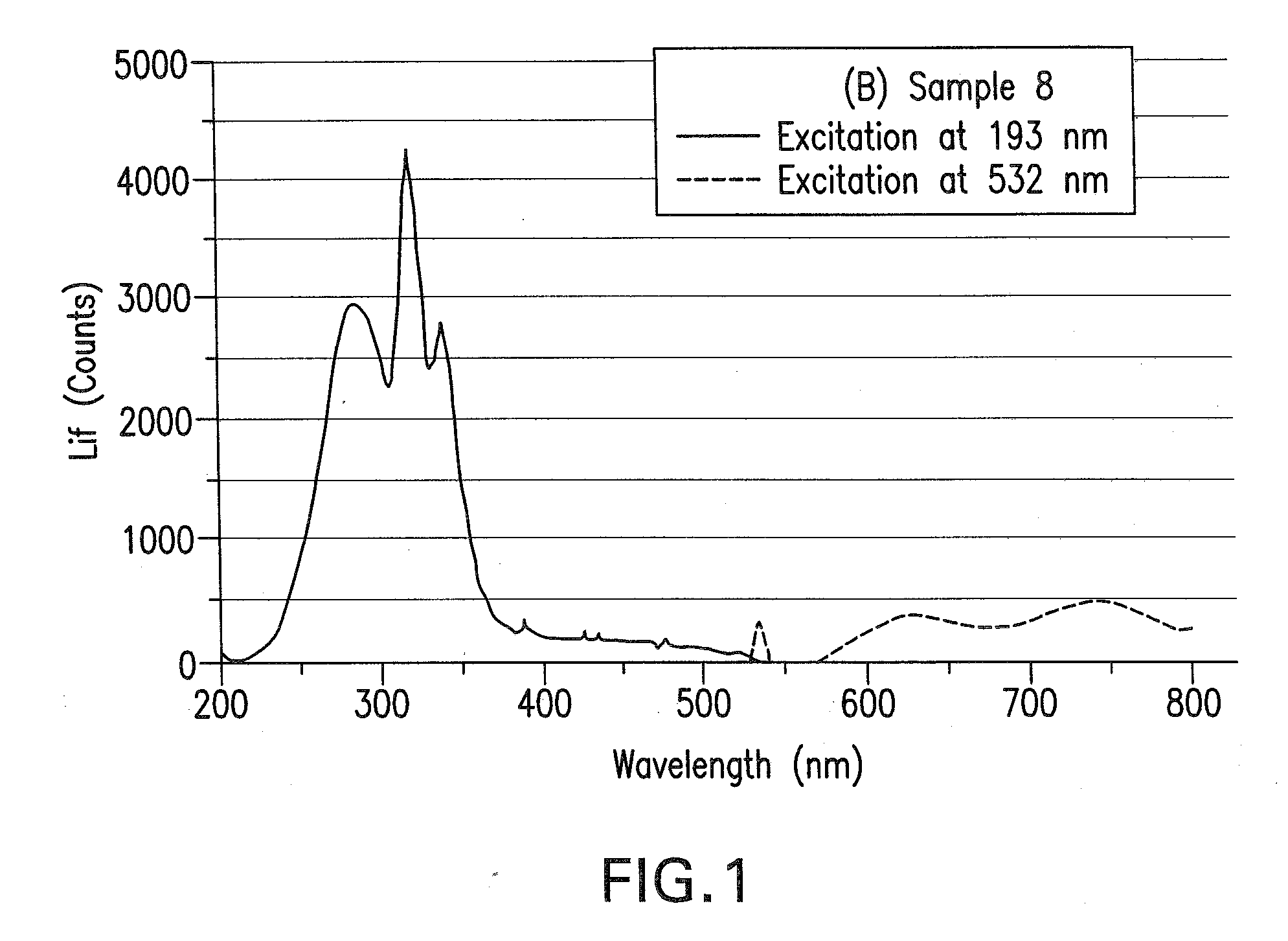

[0050]A 3 cm×3 cm sample was broken off of a polycrystalline ingot made from melted calcium fluoride powder. This crystal sample was irradiated in a holder with about 10,000 pulses (3 min at 60 Hz) of light with an energy density of 30 mJ / cm2 from an ArF excimer laser. Subsequently immediately after pre-irradiation and after a waiting time of 20 minutes the sample was irradiated with light at 532 nm (GLIF) and the intensities of the fluorescence at a wavelength of 740 nm were measured by means of a CCD camera (Spectrometer system with CCD camera as detector). The measurement occurred by means of a CCD camera as described in the already mentioned WO 2004 / 027395. The normalized value of Z is calculated according to the above-described equation 1:

Z=(I2,λ1,λ2−I1,λ1,λ2) / I2,λ1,λ2 (1).

The following measured fluorescence intensities of the fluorescence at 740 nm were obtained by excitation with wavelengths λ1a of 532 nm or λ1b of 635 nm for the different CaF2 samples no. 1 to 5. The result...

example 2

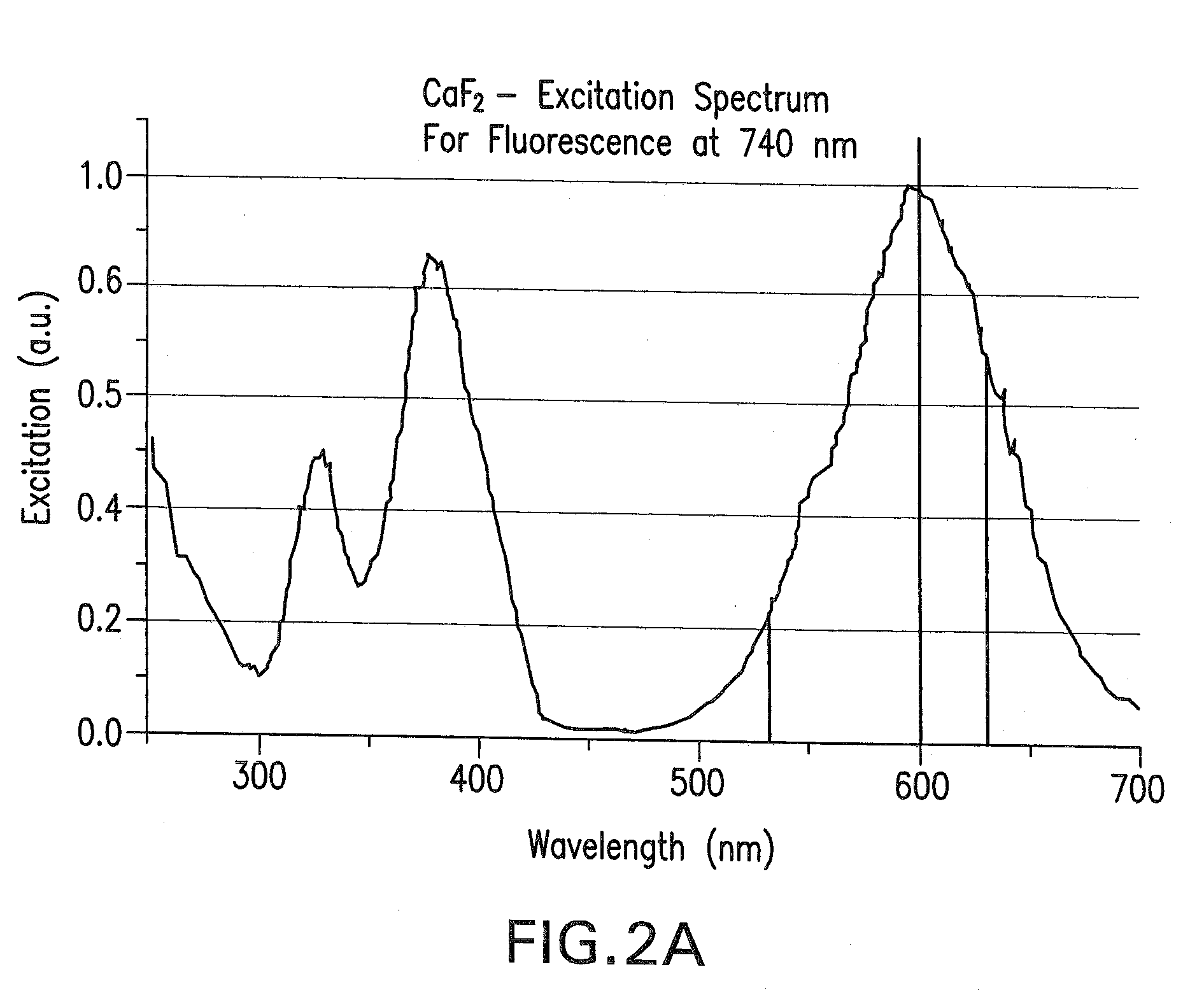

[0052]A previously obtained CaF2 crystal was pre-irradiated with 10,000 laser pulses from an ArF laser at a repetition rate of 60 Hz with an energy density of 10 mJ / cm2. Subsequently this sample was irradiated with a green solid state laser with a wavelength of 532 nm and fluorescence intensities were measured immediately after pre-irradiation and also after 15, 10, 20, 30, and 45 minutes. The intensities of the fluorescence were measured at wavelengths of 630 nm and 740 nm. The results are illustrated in the appended FIGS. 3A and 3B.

[0053]While the invention has been illustrated and described as embodied in a method of determining the laser stability of optical materials, crystals selected according to the method, and uses of the selected crystals, it is not intended to be limited to the details shown, since various modifications and changes may be made without departing in any way from the spirit of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelength range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com