Electrochemical Treatment Of Substrates

a technology of electrochemical treatment and substrate, which is applied in the direction of isotope separation, chemical/physical/physicochemical processes, energy-based chemical/physical/chemical processes, etc., can solve the problems of increasing the difficulty and cost of connecting each electrode independently, and reducing the efficiency of product production, so as to increase the throughput and efficiency of product production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

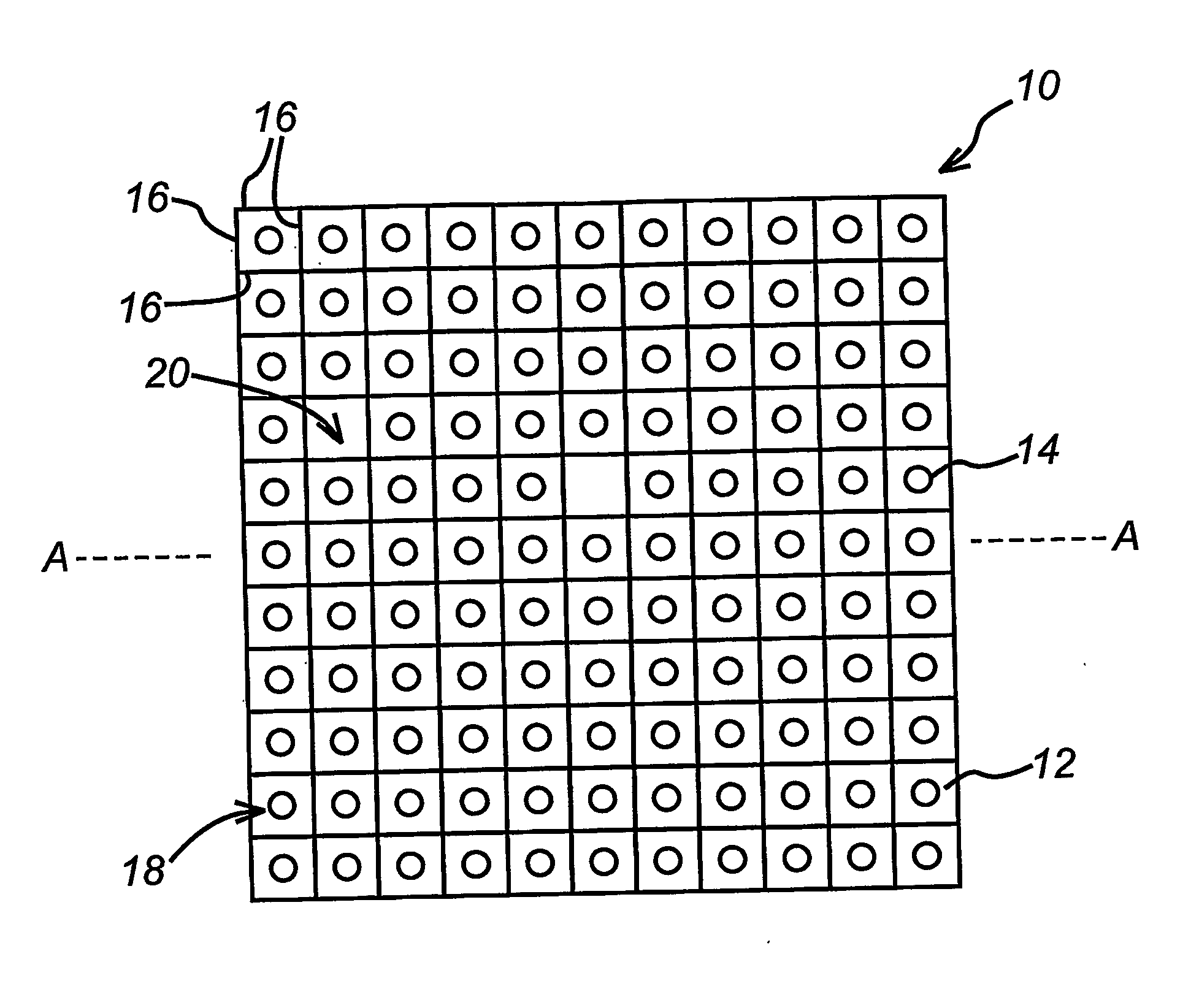

[0147]FIGS. 1 to 6 show various embodiments of a device (10) for electrochemically modifying the surface of a substrate (not shown). In FIG. 1, the device (10) has an array of individually addressable second electrodes (14). The second electrodes (14) are circular and are mounted on a support (12). A common first electrode (16) is arranged on the support (12) in the form of a grid. The common first electrode (16) defines cells (18, 20). Most cells (18) contain a single second electrode. A minority of cells (20) do not contain a second electrode.

second embodiment

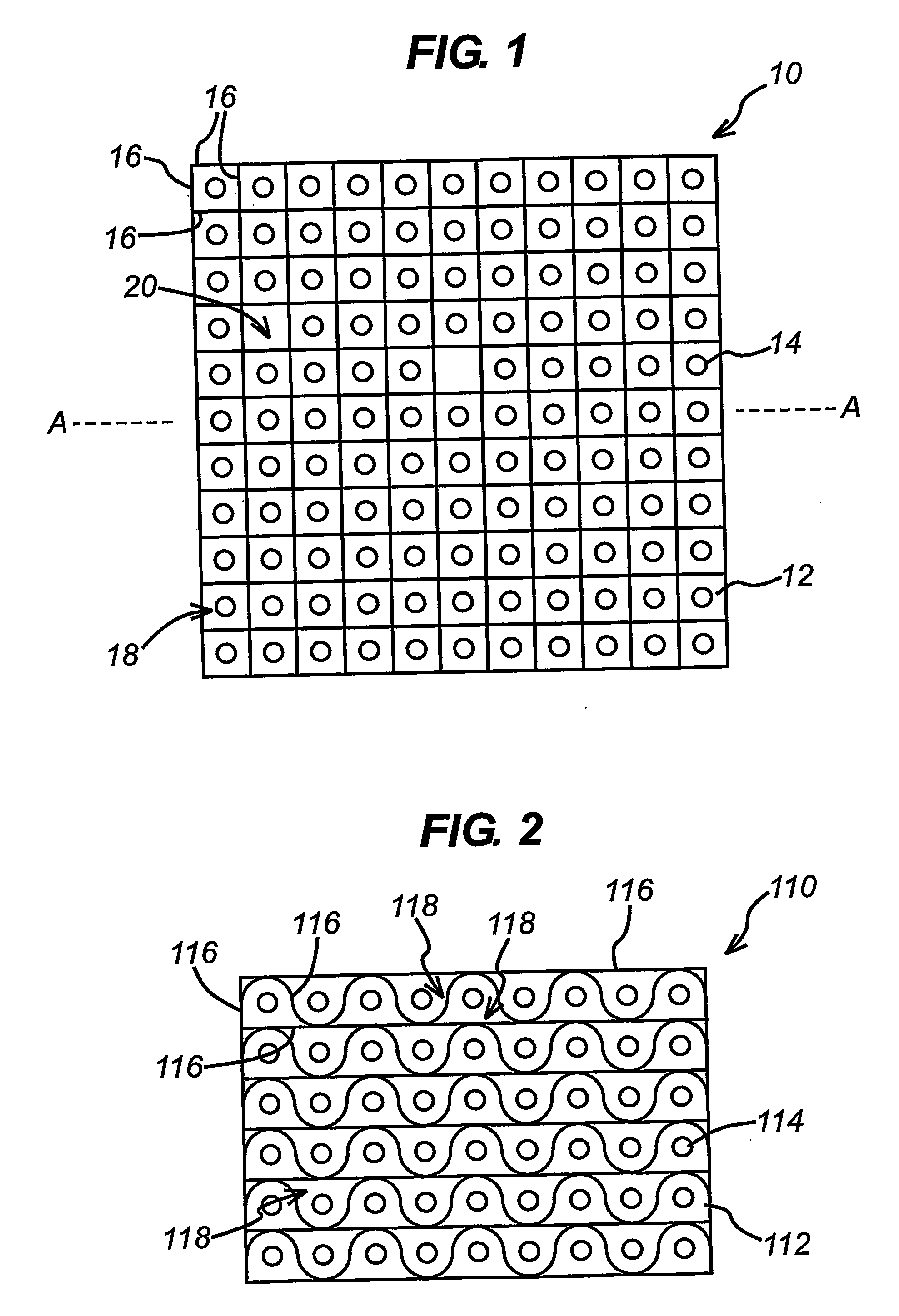

[0148]In FIG. 2, there is shown a portion of a device (110). The device (116) has an array of individually addressable second electrodes (114). The second electrodes (114) are mounted on a support (112). A common first electrode (116) is arranged on the support (112) in tessellating pattern. The common first electrode (116) defines cells (118). In the portion of the device (110) shown in FIG. 2, a single second electrode (114) is positioned within each cell (118).

third embodiment

[0149]In the device (210), a portion of which is shown in FIG. 3, there is an array of individually addressable second electrodes (214). The second electrodes (214) have a square shape and are mounted on a support (212). A common first electrode (216) is arranged on the support in a net-like pattern. The common first electrode (216) defines cells (218). In the portion of the device (210) shown in FIG. 3, a single second electrode (214) is positioned within each cell (218).

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com