Compound and method of making the compound

- Summary

- Abstract

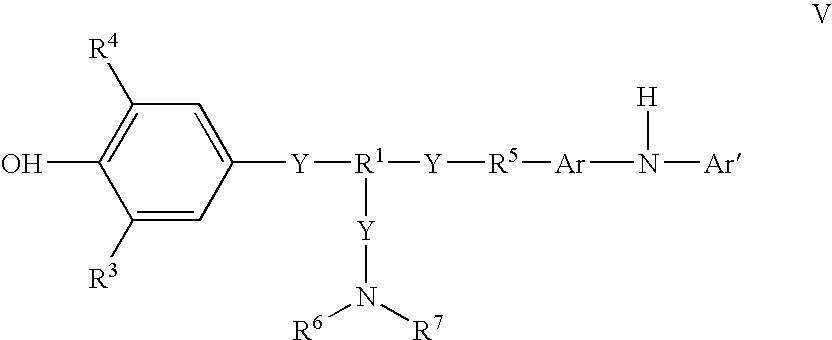

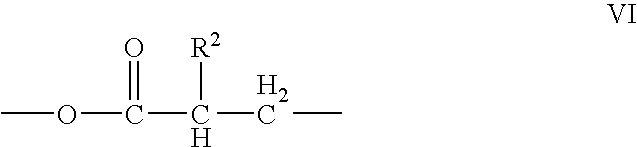

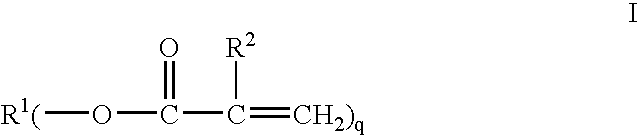

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Method of Making a Compound

[0054]An exemplary process for making an compound of the present application was carried out as follows:

[0055]Step 1: A 1-liter 4-neck flask equipped with nitrogen sub-surface was charged with 236.8 g of trimethylolpropane triacrylate (TMPTA), 300 g methanol, and 0.8 g of laural mercaptan. To this solution 192.8 g of bis(2-ethylhexylamine) was added dropwise over 4 hr period and then allowed to stir at room temperature for 3 hrs. The temperature was then raised to 65° C. to distill methanol and finally vacuum stripped and filtered over Celite. A total of approximately 424 g of product was isolated. % N=2.74%

[0056]Step 2: A 500 mL flask was charged with 149 g of process oil, 64 g of 2,6-di-tert butylphenol and 1 g of potassium hydroxide. The mixture was heated to about 120° C. and then mild vacuum was applied to remove about 1.3 ml of distillate. Vacuum was removed and the mixture was then heated to 140° C. 161 g of the product isolated from step 1 was then...

example 2

Method of Making an Compound

[0058]Another exemplary process for making a compound of the present application was carried out as follows.

[0059]A 500 ml flask was charged with 74 g of TMPTA and 240 g of butanol. The flask was equipped with nitrogen sub-surface and reflux condenser and heated to about 80° C. 46 g of NPPDA was added in portions over 30 min and the mixture was then heated to reflux for 8 hrs. 51.5 g of 2,6-di-tert butylphenol and 0.7 g potassium hydroxide were added and the mixture was again held at reflux for 7 hrs. The reflux condenser was replaced with a distillation apparatus and the mixture was heated to 145° C., during which almost 200 ml butanol was removed. The mixture was cooled to 65° C. and 60.3 g of bis(2-ethylhexyl)amine was added dropwise over a 2 hr period. The mixture was held at 65° C. for 3 hrs and then vacuum stripped. 7 g of talc was added and stirred for 30 minutes, followed by filteration through paper to remove solids. The filtered product had 4.22...

example 3

Evaluation of Engine Oils Containing the Compound of Example 1 in the Thermo-Oxidation Engine Oil Simulation Test (TEOST MHT-4)

[0060]The TEOST MHT-4 is a standard lubricant industry test for the evaluation of the oxidation and carbonaceous deposit-forming characteristics of engine oils. The test is designed to simulate high temperature deposit formation in the piston ring belt area of modern engines. The test utilizes a patented instrument (U.S. Pat. No. 5,401,661 and U.S. Pat. No. 5,287,731; the disclosure of each patent is hereby incorporated by reference in its entirety) with the MHT-4 protocol being a relatively new modification to the test. Details of the test operation and specific MHT-4 conditions have been published by Selby and Florkowski (Selby et al.) in a paper entitled, “The Development of the TEOST Protocol MHT as a Bench Test of Engine Oil Piston Deposit Tendency” presented at the 12th International Colloquium Technische Akademie Esslingen, Jan. 11-13, 2000. Wilfried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com