Systems and Methods of Cooling Blast Furnaces

a technology of systems and methods, applied in indirect heat exchangers, furnaces, lighting and heating apparatus, etc., can solve the problems of affecting the installation process, affecting the cooling effect, and the refractory lining may be subject to extreme mechanical wear, so as to improve the installation effect, simplify the design, and increase the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

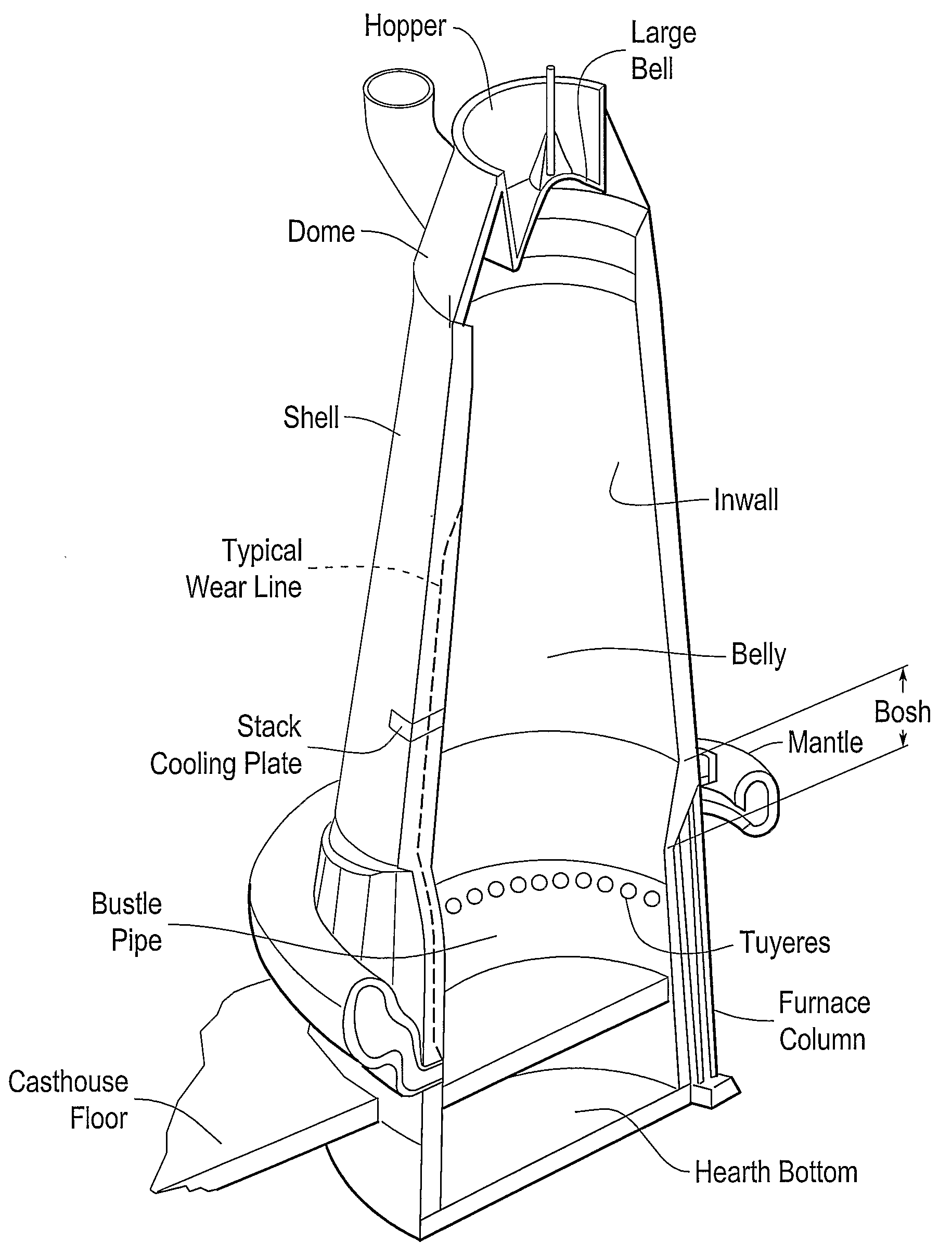

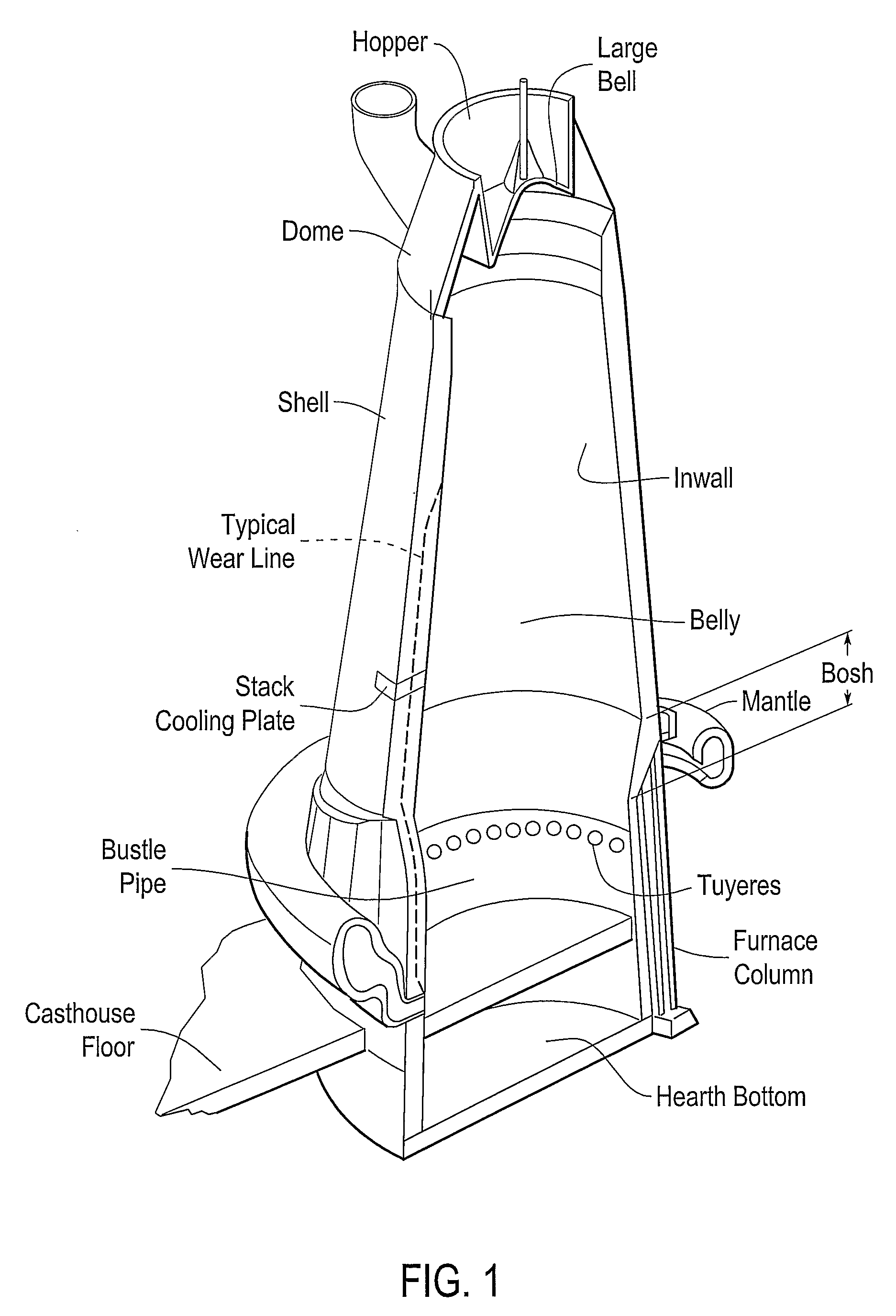

[0023]Blast furnaces may be used to convert iron bearing raw materials into a form that can be easily transformed into steel. A blast furnace is typically a large refractory lined steel vessel in which pellets and / or sinter, coke, and flux materials may be charged into the furnace top. High temperature air at high pressure may be blown into the bottom of the furnace. Molten iron and slag accumulate at the bottom of the furnace and may be removed periodically. FIG. 1 shows an exemplary blast furnace.

[0024]As shown in FIG. 1, the lower portion of the furnace is called the hearth. The steel jacket surrounding the hearth is vertical or slightly conical. The jacket may be lined with refractory material (e.g., carbon, graphite, silicon carbide, and / or ceramics) and may be cooled with staves or external shell sprays. The hearth bottom may be lined with refractory material. One or more iron notches may be located on or above the hearth floor. The iron notches permit iron and or slag to be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com