Integrated hydrometallurgical and pyrometallurgical processing of base-metal sulphides

a hydrometallurgical and pyrometallurgical technology, applied in the field of base metal recovery, can solve the problems of inefficiency of roasting, inability to apply conventional smelting processes to lower grade copper concentrates, complex hydrometallurgical processing routes, etc., and achieve the effect of improving the economics of the whole integrated process, maximizing the recovery of copper from the original copper-containing feedstock, and improving the chemical efficiency and effect of the whole process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

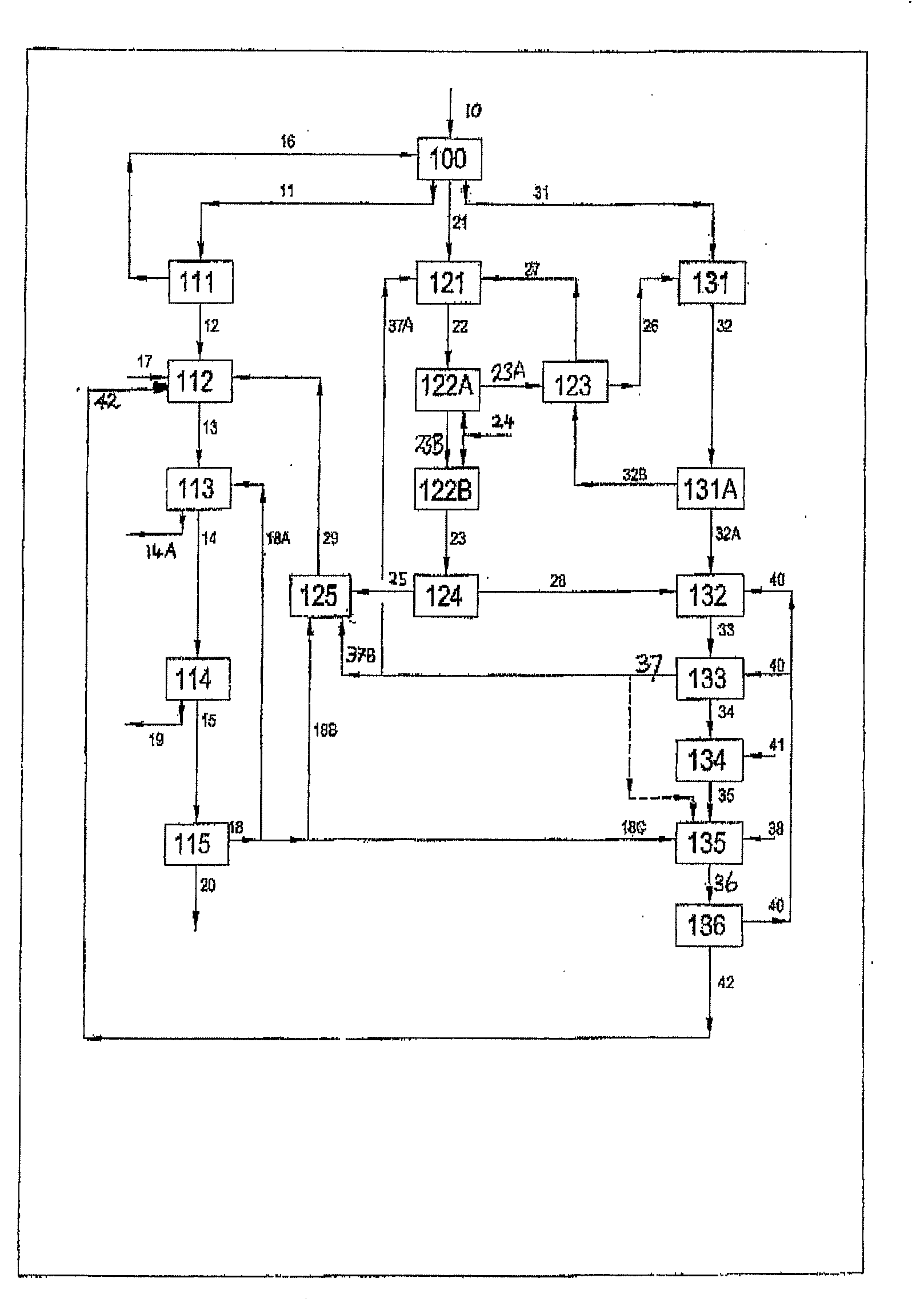

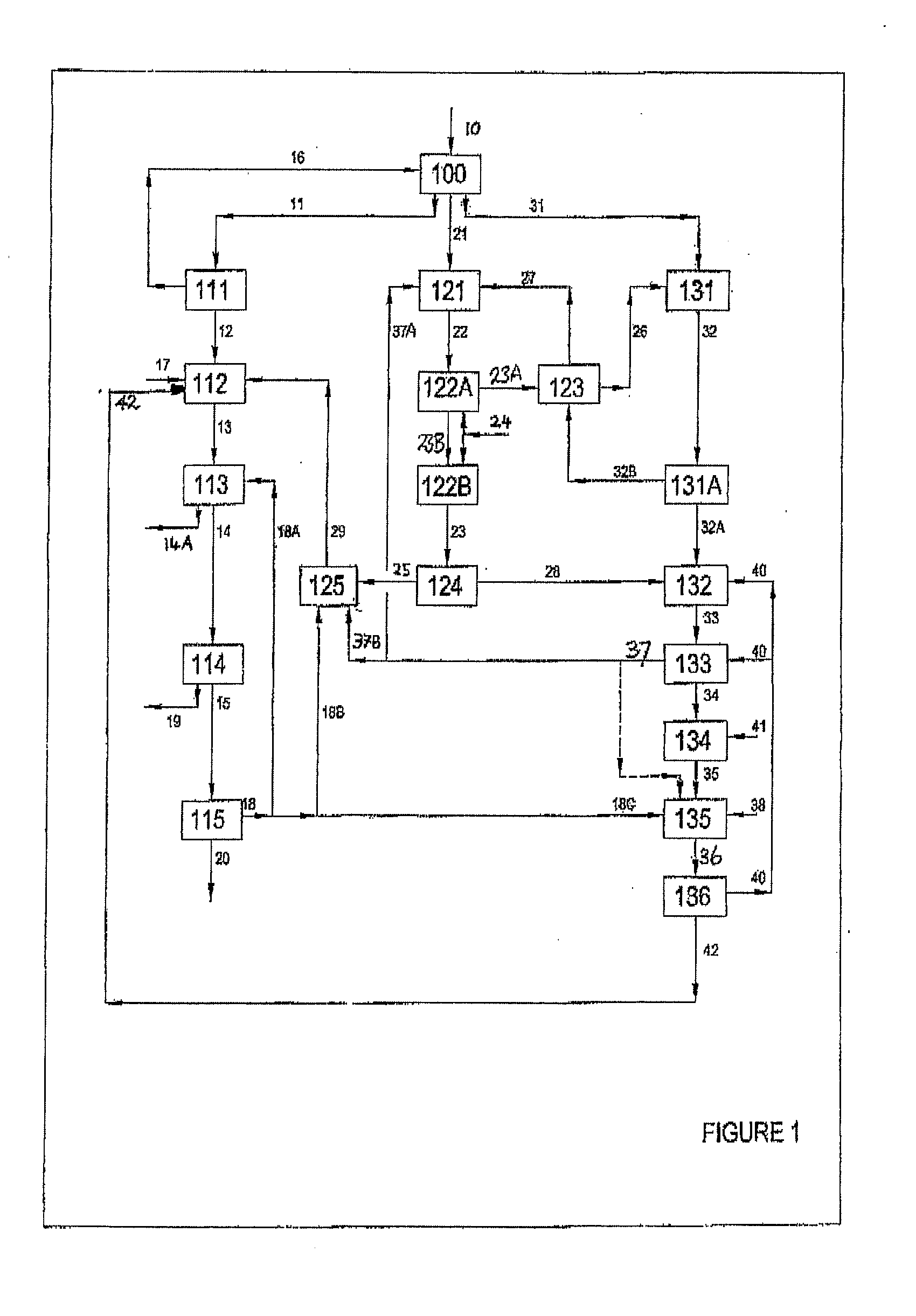

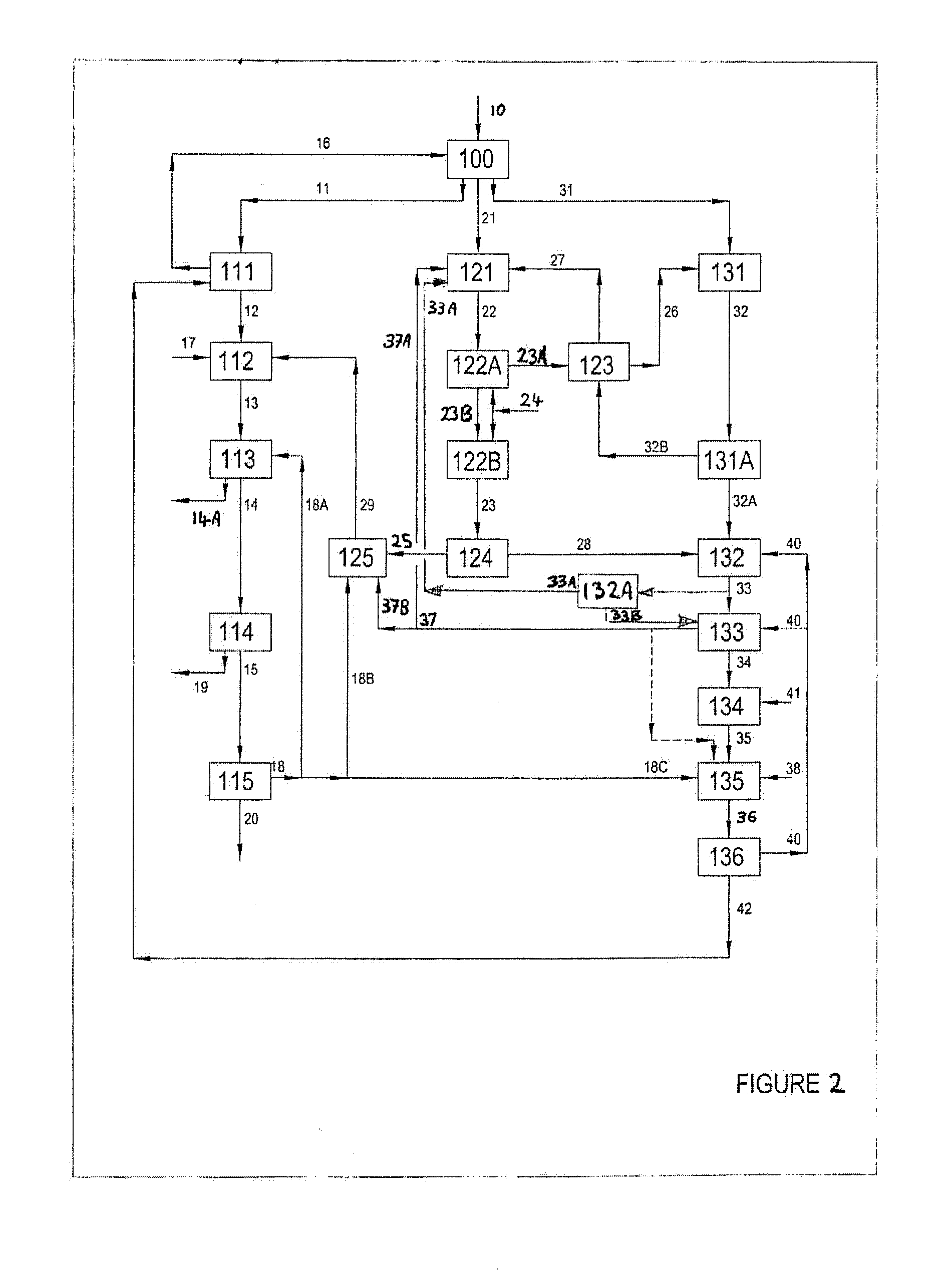

Image

Examples

example 1

[0084]A copper-iron sulphide concentrate containing about 34.5% copper and 1.9% iron and consisting predominantly of chalcopyrite and having a size range of about 80% passing 75 micron was subjected to pressure oxidation at 225° C. using a pulp density of 20% solids (w / w). More than 99% of the contained copper was leached after 120 minutes.

[0085]A second portion of the same concentrate was ground to 80% passing 23 micron and was reacted at a pulp density of 40% solids (w / w) at 180° C. with a copper sulphate solution containing 90 g / L of copper derived from the above pressure oxidation test. No reagents or chemicals were added to the upgrading step. Copper in solution dropped to less than 1 g / L after 15 minutes, and the copper content of the concentrate upgraded to above 45% w / w while the iron content was lowered to about 14% w / w.

example 2

[0086]The same copper-iron sulphide concentrate described in Example 1 was subjected to pressure oxidation at 210° C. and a pulp density of 25% solids (w / w) for a period of 180 minutes. Copper extraction was in excess of 97%.

[0087]Another portion of the same concentrate was reacted at a pulp density of 21.5% solids (w / w) at 180° C. with a copper sulphate solution containing 82 g / L of copper derived from the above pressure oxidation step. No reagents or chemical were added to the upgrading stage. Copper in solution dropped to less than 6 g / L after 180 minutes, and the copper content of the concentrate upgraded to above 55% w / w while the iron content was lowered to below 9% w / w.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com