Smokeless tobacco

a technology of smokeless tobacco and tobacco, which is applied in the field of tobacco, can solve the problems of increasing the cost of shipping and storage of smokeless tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

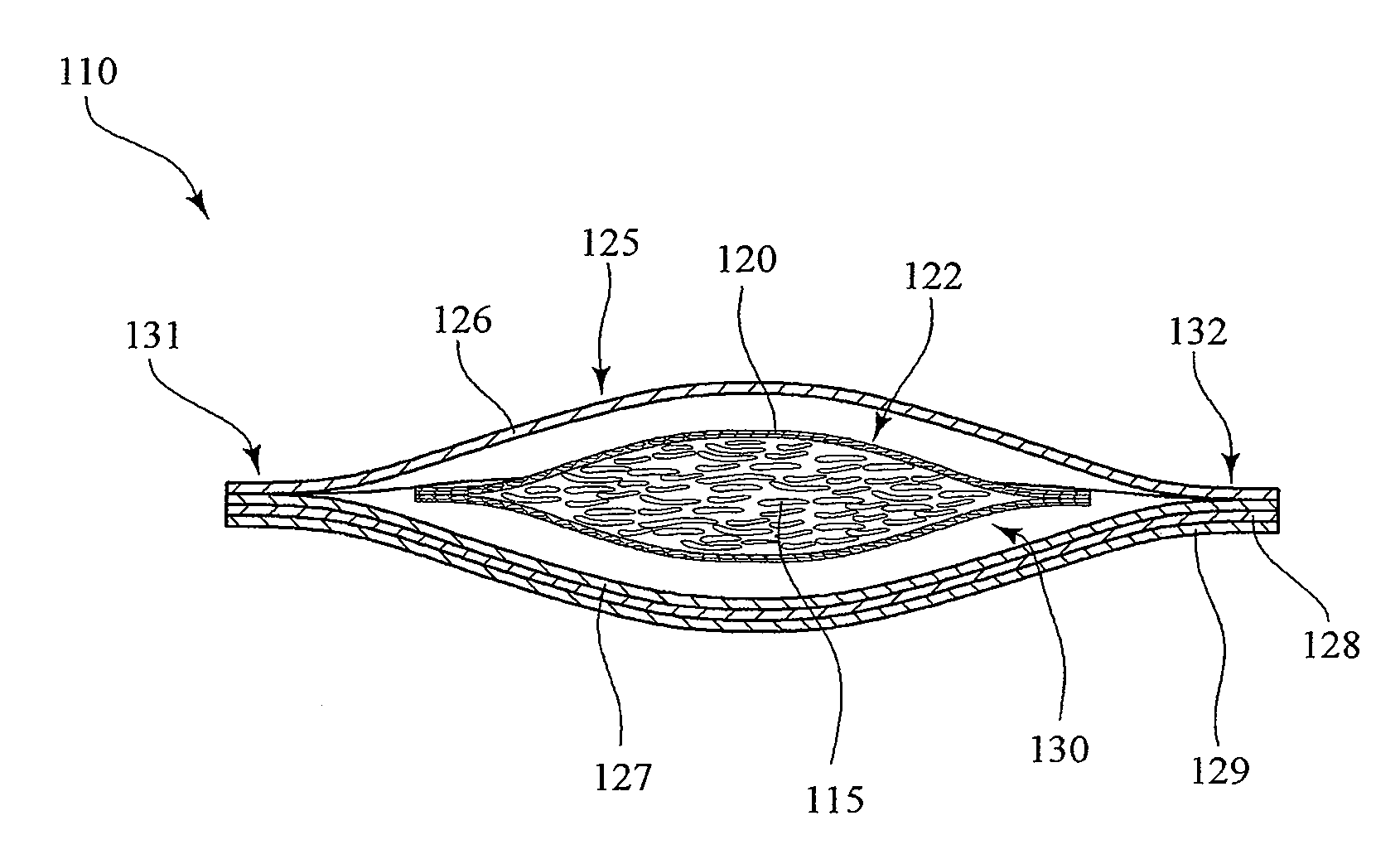

[0071]A tobacco formulation in the form of a somewhat flat strip or film is provided in the following manner.

[0072]Tobacco material, comprised of a mixture of cured and aged flue-cured, burley and Oriental lamina is provided in a strip or leaf form, and at a moisture of about 9 percent. A portion of this tobacco mixture is washed with water, and the solubles or extractable portion that is collected is discarded, and the remaining water insoluble solids (e.g., pulp portion) is dried. The resulting dried pulp portion then is mixed with the retained untreated portion of the original tobacco mixture. That tobacco mixture then is milled to a particle size that passes through a 150 Tyler mesh screen.

[0073]The resulting tobacco mixture is further mixed with other ingredients to form the a formulation that contains about 40 parts of milled tobacco lamina, about 25 parts calcium carbonate, about 15 parts binder (which may be composed of pectin, gelatin, sodium alginate and starch), about 15 ...

example 2

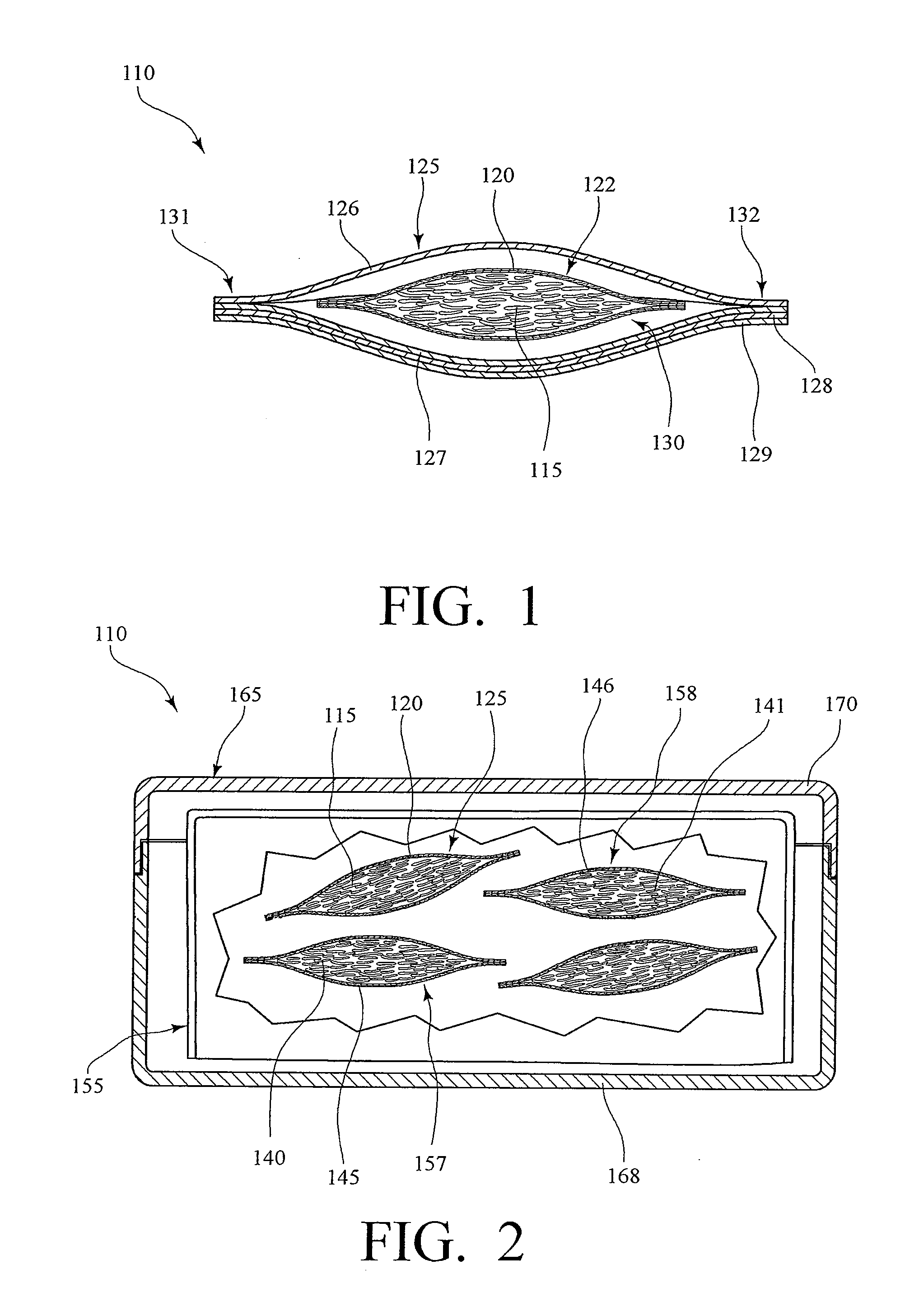

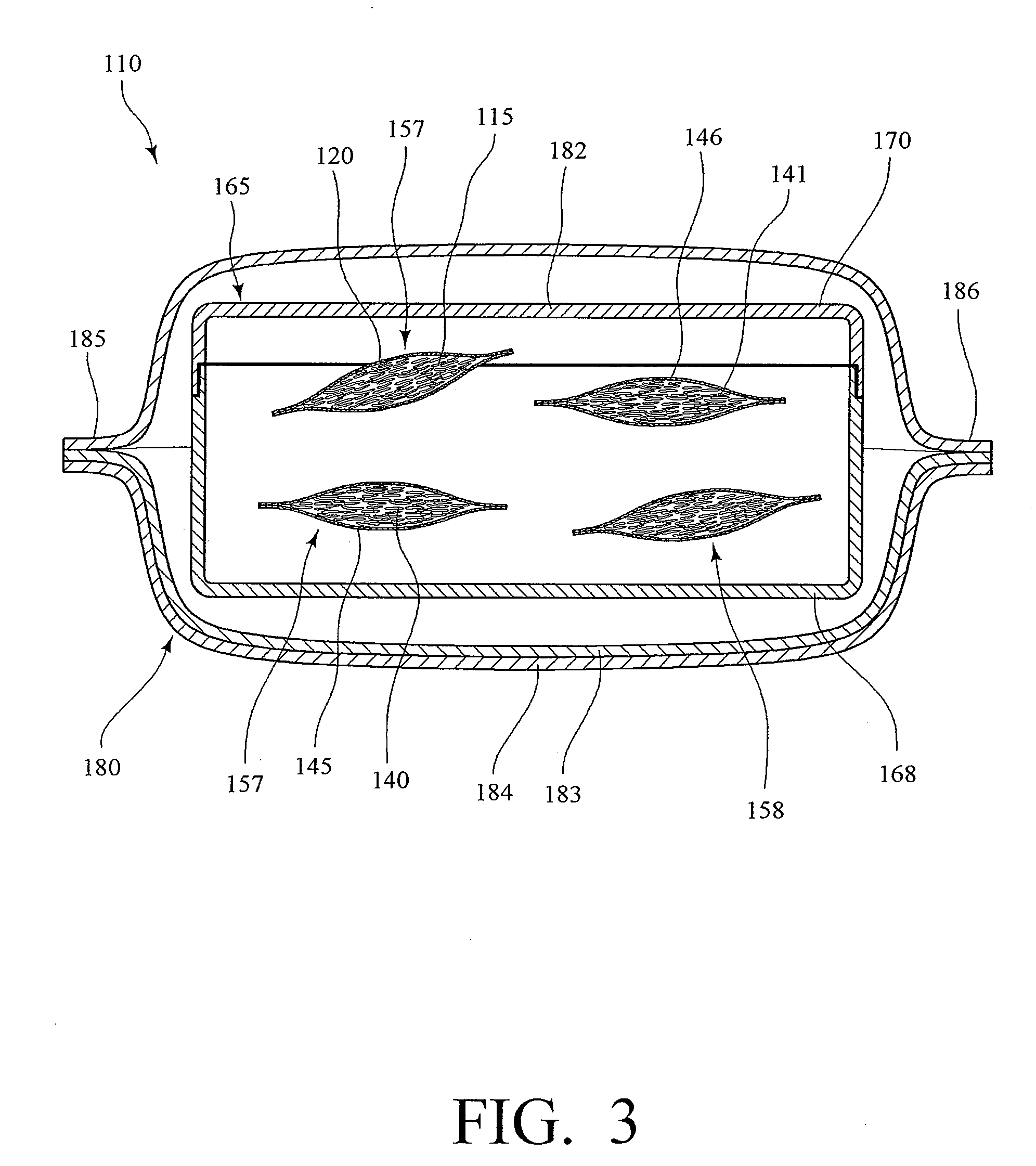

[0078]The smokeless tobacco products that are preferably non-chewable tobacco products that are intended to be placed between the cheek and the gum of the mouth are provided as follows. Preferred smokeless tobacco products, when used orally, completely dissolve in the mouth leaving little to no solid or granular residue, while dispensing or dispersing tobacco components, and while providing a pleasant trigeminal and organoleptic experience.

[0079]Cured and / or aged tobacco lamina or stems is provided in a strip or shredded form, and at a moisture content of about 9 percent, or less. Tobacco types can include flue-cure, burley and Oriental tobaccos, and various combinations thereof. In addition, specialty or exotic types of tobaccos, including tobaccos such as Perique and Cavendish, also can be incorporated within blends of tobacco materials. The lamina or stem is milled under cryogenic conditions, or any other suitable dry milling means, to a fine ground form. The powder is sufficient...

example 3

[0084]A dry mix of about 200 g to about 225 g of granulated tobacco powder of the type described previously in Example 2, a flavoring agent (e.g., mint flavor) and optionally sodium chloride are mixed for about 5 minutes in a table-top Model P400 Popiel™ Automatic Pasta Maker (available from Ronco Inventions, LLC, Chestworth, Calif.). Then, about 48 g portion of a premixed warm aqueous solution (e.g., about 40 g water and about 8 g glycerin) is added to the dry mix. Those contents are mixed for about 3 minutes, or until small pea-like size lumps develop. The pea-like mixture is subsequently extruded via selected dies to obtain flat pasta-like sheets (1.4 cm wide×30 cm length×0.1 to 0.7 cm depth) or noodle-like cylindrical rods (0.1 to 0.7 cm diameter×12 to 24 cm length). The pasta-like sheet is further cut into smaller square or rectangular pieces to obtain pellets that each weigh about 185 mg to about 250 mg. Generally wafer shaped pieces, each weighing about 185 mg to about 250 mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com