Thermosetting encapsulation adhesive sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

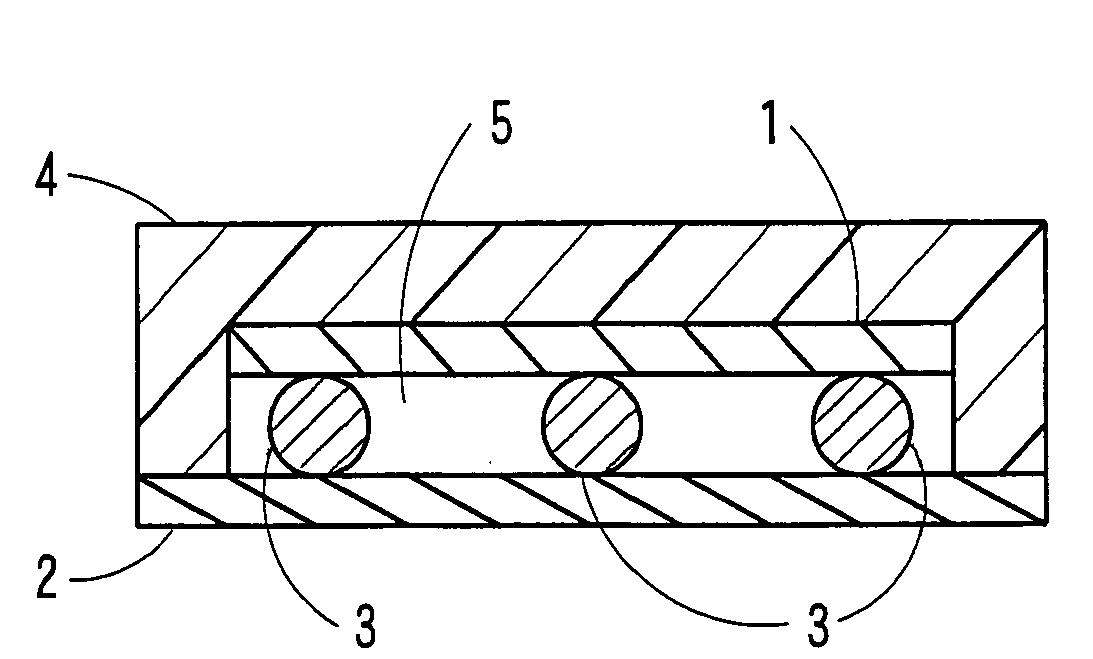

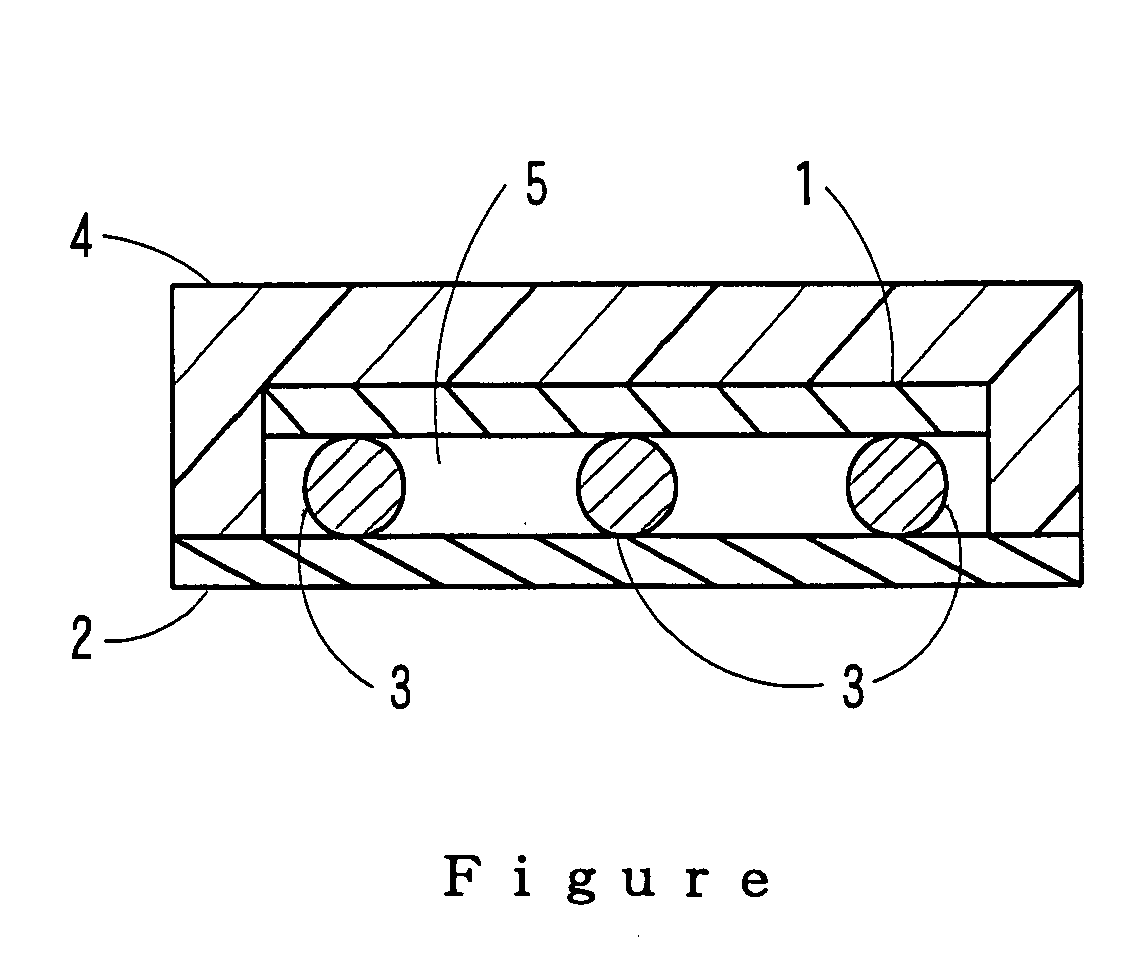

Image

Examples

examples

[0040]Inventive examples will hereinafter be described in conjunction with comparative examples. However, it should be understood that the present invention be not limited to these inventive examples.

[0041]First, the following ingredients were prepared.

Epoxy resin-a: A naphthalenediol epoxy resin (ESN-355 available from Tohto Kasei Co., Ltd.)

Epoxy resin-b: A bisphenol-A epoxy resin (EPICOAT 828 available from Japan Epoxy Resin Co., Ltd.)

Epoxy resin-c: A trishydroxyphenylmethane epoxy resin (EPPN-501HY available from Nippon Kayaku Co., Ltd.)

Phenol resin-a: A novolak phenol resin (H-4 available from Meiwa Plastic Industries, Ltd.)

Phenol resin-b: A novolak phenol resin (DL-65 available from Meiwa Plastic Industries, Ltd.)

Acryl resin-a: An acryl copolymer (TEISAN RESIN SG-70L available from Nagase ChemteX Corporation)

Acryl resin-b: An acryl copolymer (TEISAN RESIN SG-P3 available from Nagase ChemteX Corporation)

Curing accelerating agent-a: Tetraphenylphosphonium tetraphenylborate (TPP-K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com