Printed circuit board with embedded chip capacitor and chip capacitor embedment method

a technology of embedded chips and printed circuit boards, which is applied in the direction of cross-talk/noise/interference reduction, sustainable manufacturing/processing, and final product manufacturing, etc., can solve the problems of obstructing the accurate operation of the rf circuit, difficult to accurately receive the signal having a certain frequency band, and difficulty in mixing signals, etc., to achieve simple structure, prevent noise, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

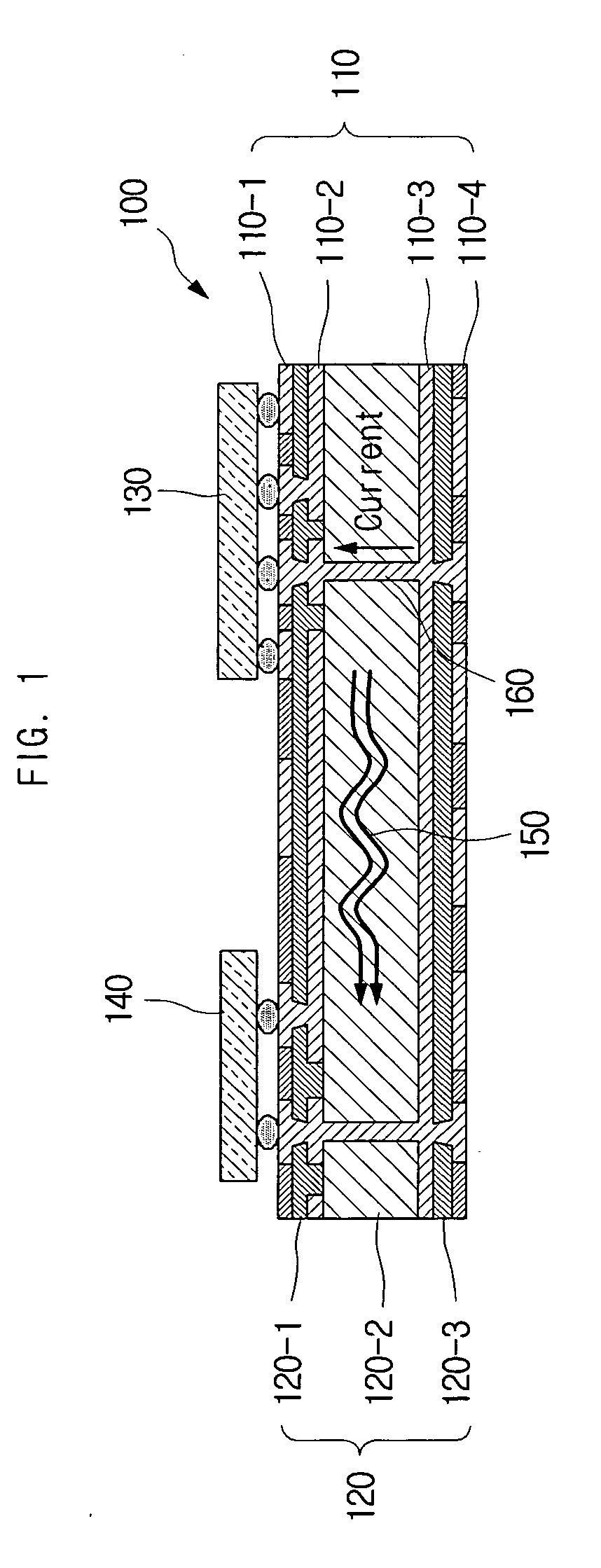

[0073]FIG. 6 is a side view showing a printed circuit board having an embedded chip capacitor in accordance with the present invention, and FIG. 7 is a schematic view showing an equivalent circuit of the printed circuit board shown in FIG. 6.

[0074]Referring to FIG. 6, a printed circuit board having an embedded chip capacitor in accordance with a first embodiment of the present invention can include a first conductive layer 310, a second conductive layer 320, a dielectric layer 330, a chip capacitor 340 and a via 350.

[0075]Any one of the first conductive 310 and the second conductive layer 320 can be used as a power layer, and the other can be used as a ground layer. Accordingly, the first conductive 310 and the second conductive layer 320 can be away from each other through the dielectric layer 330 placed therebetween in order to allow the first conductive 310 and to be electrically disconnected to the second conductive layer 320.

[0076]The chip capacitor 340 can be embedded between ...

third embodiment

[0084]Accordingly, the printed circuit board in accordance with the second or third embodiment of the presented invention can more efficiently and universally use the function as the electromagnetic bandgap structure intercepting the transfer of an electromagnetic wave having a desired frequency band by the etched pattern 370, which is additionally connected to the chip capacitor 340 in series, together with the inductance component by the via 350 (refer to FIG. 8C and FIG. 9C). This is because adjusting the inductance value according to the design modification of the diameter, length and shape of the via 350 between any two conductive layers of the printed circuit board having the determined size, thickness and area size can not but be partially restricted.

[0085]As compared with this, to obtain a desired inductance value by designing and controlling the shape, length, width and area size of the etched pattern 370 can be more easily performed on the design. This can increase the usa...

fourth embodiment

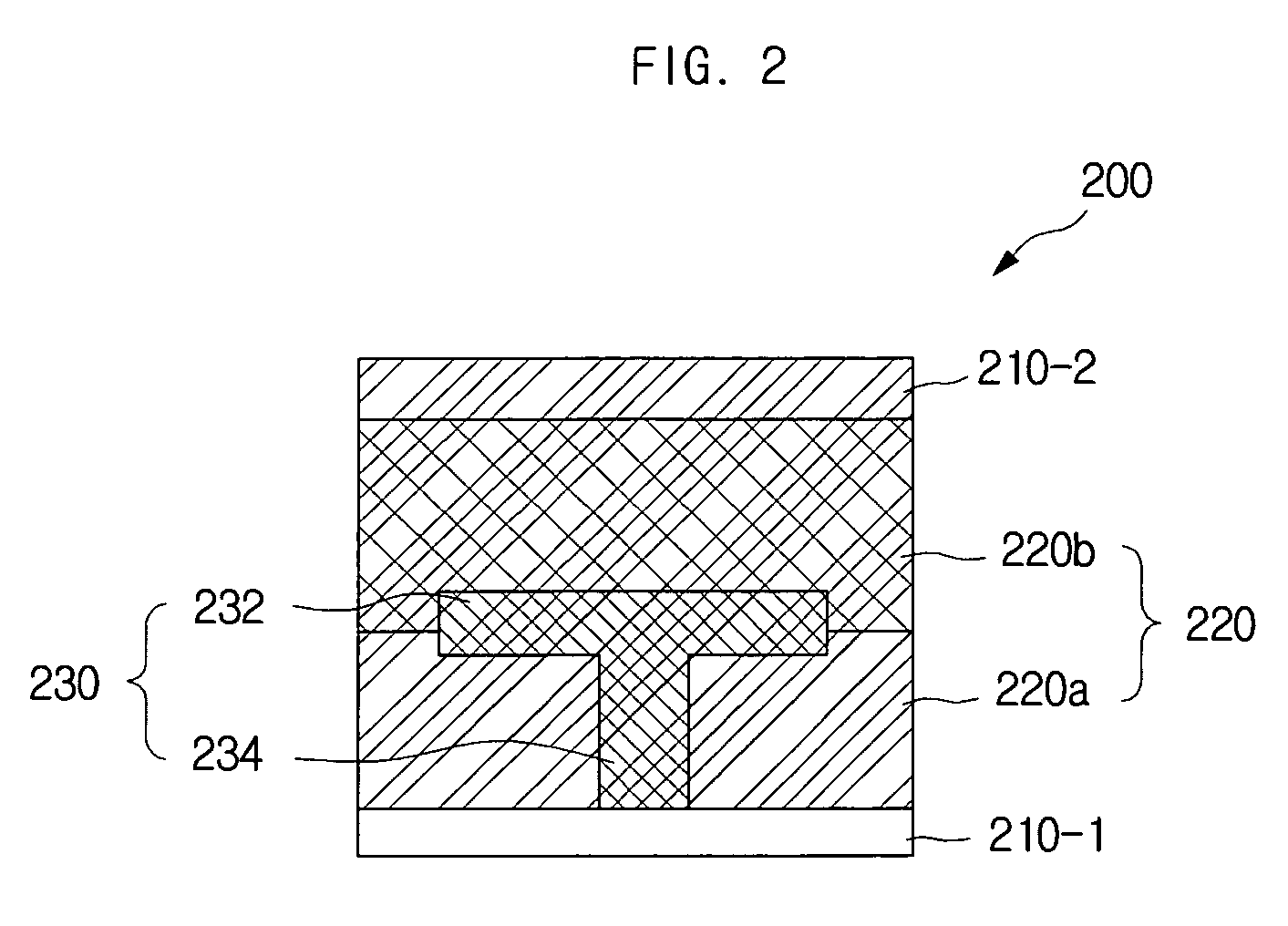

[0087]FIG. 10A is a side view showing a printed circuit board having an embedded chip capacitor in accordance with the present invention, and FIG. 10B illustrates a clearance hole when the printed circuit board shown in FIG. 10A is viewed from an upper side.

[0088]Referring to FIG. 10A and FIG. 10B, a printed circuit board having an embedded chip capacitor in accordance with a fourth embodiment of the present invention can have the shape in which a clearance hole 360 is formed in a part of the second conductive layer 320.

[0089]The reason that the clearance hole 360 is formed at the second conductive layer 320 in the printed circuit board in accordance with the fourth embodiment of the present invention is as follows. All chip capacitors embedded in the printed circuit board in accordance with the forgoing embodiments are the flake type. The flake type indicates that the electrodes are formed in an upper side and a lower side, respectively, and the dielectric member is placed between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com