Foamed polyolefin resin beads

- Summary

- Abstract

- Description

- Claims

- Application Information

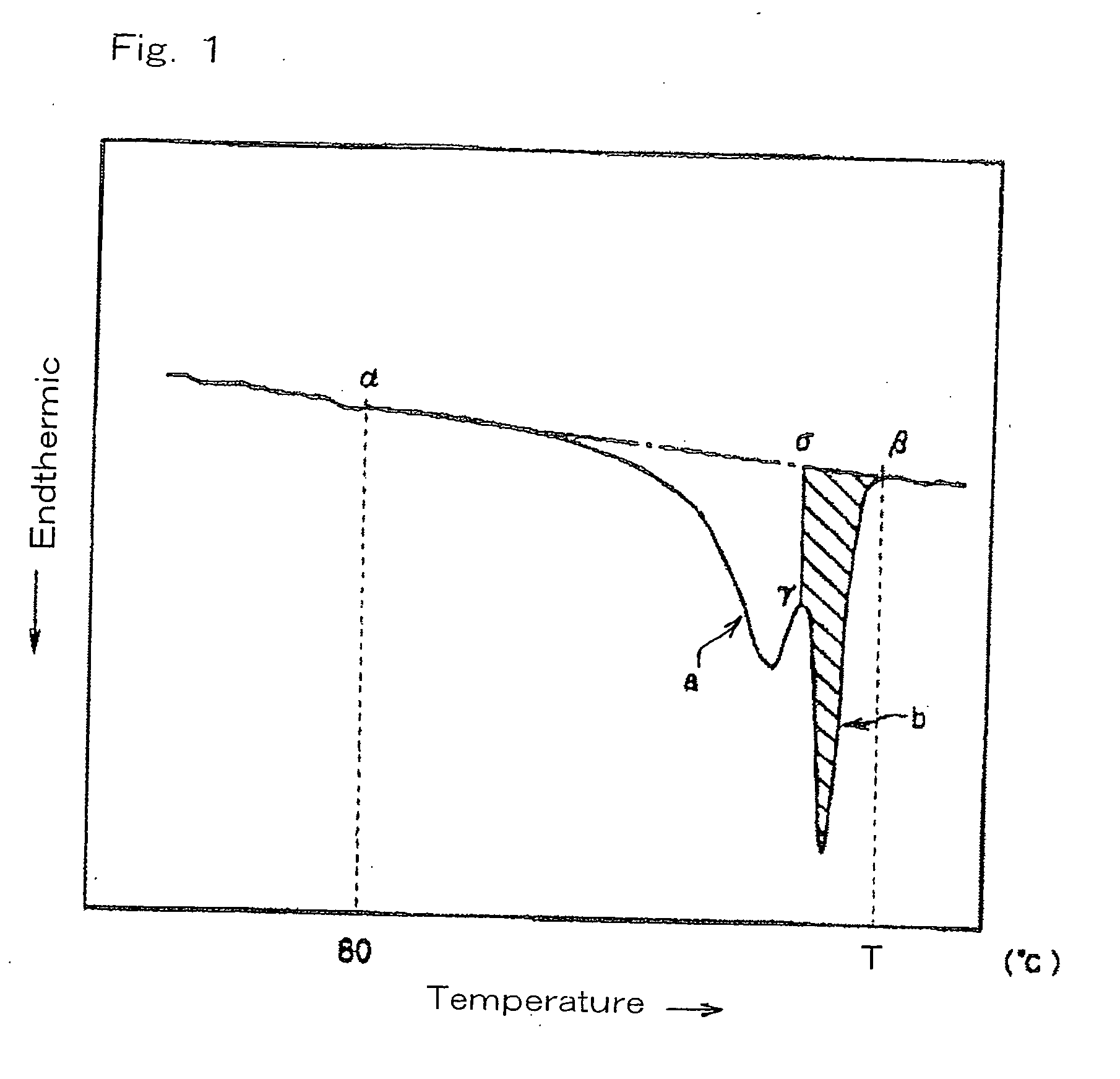

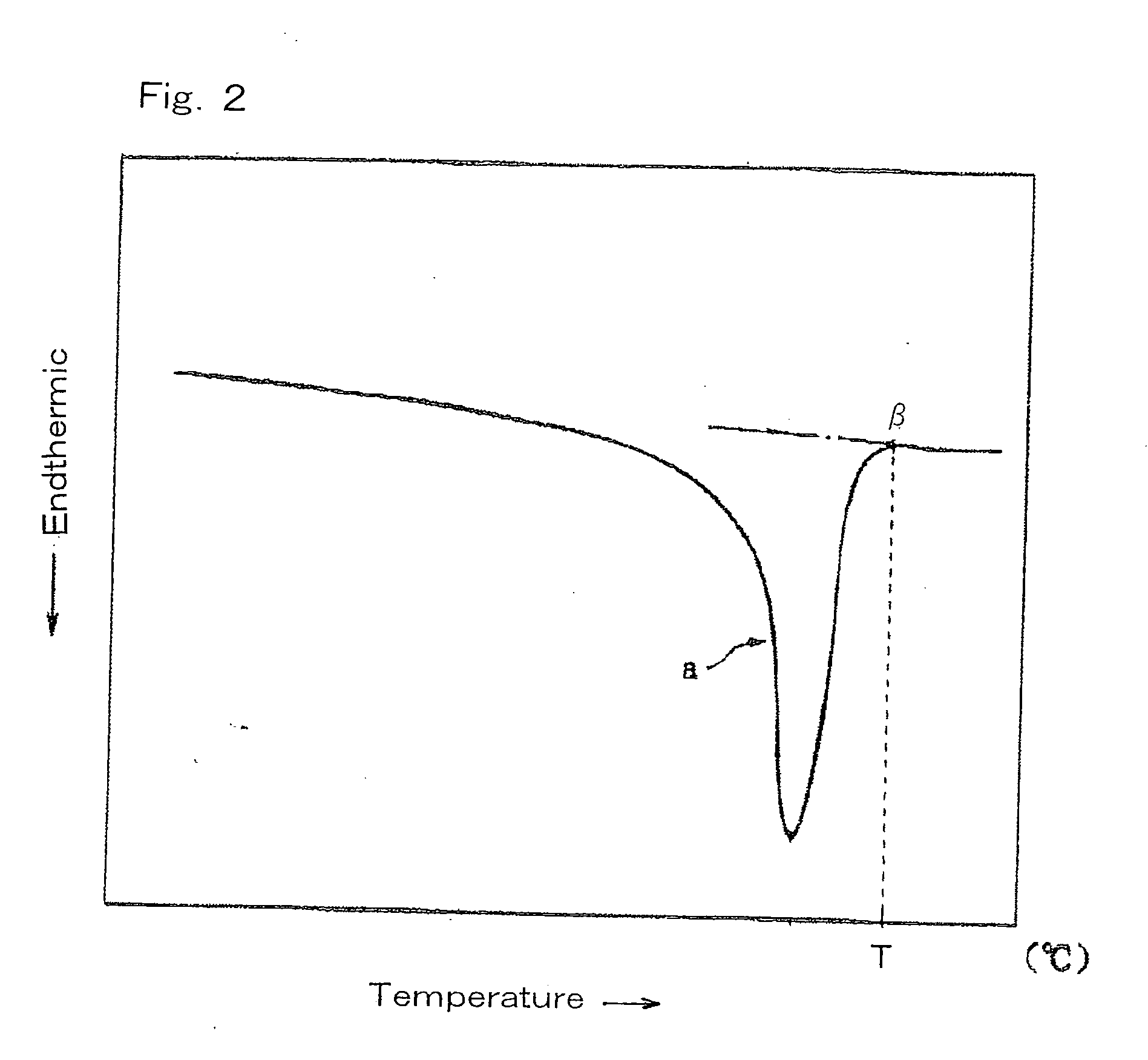

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0119]Crystalline polyolefins used in Examples and Comparative examples are shown in the following Table 1.

TABLE 1ComonomerMFR*MeltingAbbrevi-amountsg / 10pointationcatalystsBased resinscomonomers% by weightmin(° C.)Resin 1Metallocene typePropylene-ethyleneEthylene0.59.0142random copolymerResin 2Ziegler Natta typePropylene-ethyleneEthylene2.77.0142random copolymerResin 3Ziegler Natta typePropylene-ethyleneEthylene1.08.0155random copolymerResin 4Ziegler Natta typePropylene homopolymer——5.0162Resin AMetallocene typePropylene-ethyleneEthylene2.87.0125random copolymerResin BZiegler Natta typePropylene-ethyleneEthylene1.67.0135random copolymerResin CMetallocene typeLinear low density——2.0100polyethylene*MFR means a melt mass-flow rate measured by a test method A based on JIS K 7210 (1999).MRFs of the resins 1 to 4 as well as the resins A and B are values measured under conditions of a test temperature of 230° C. and a load of 2.16 kg.MFR of the resin C is a value measured under conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com