Organic Light Emitting Diode Display Device and Manufacturing Method Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

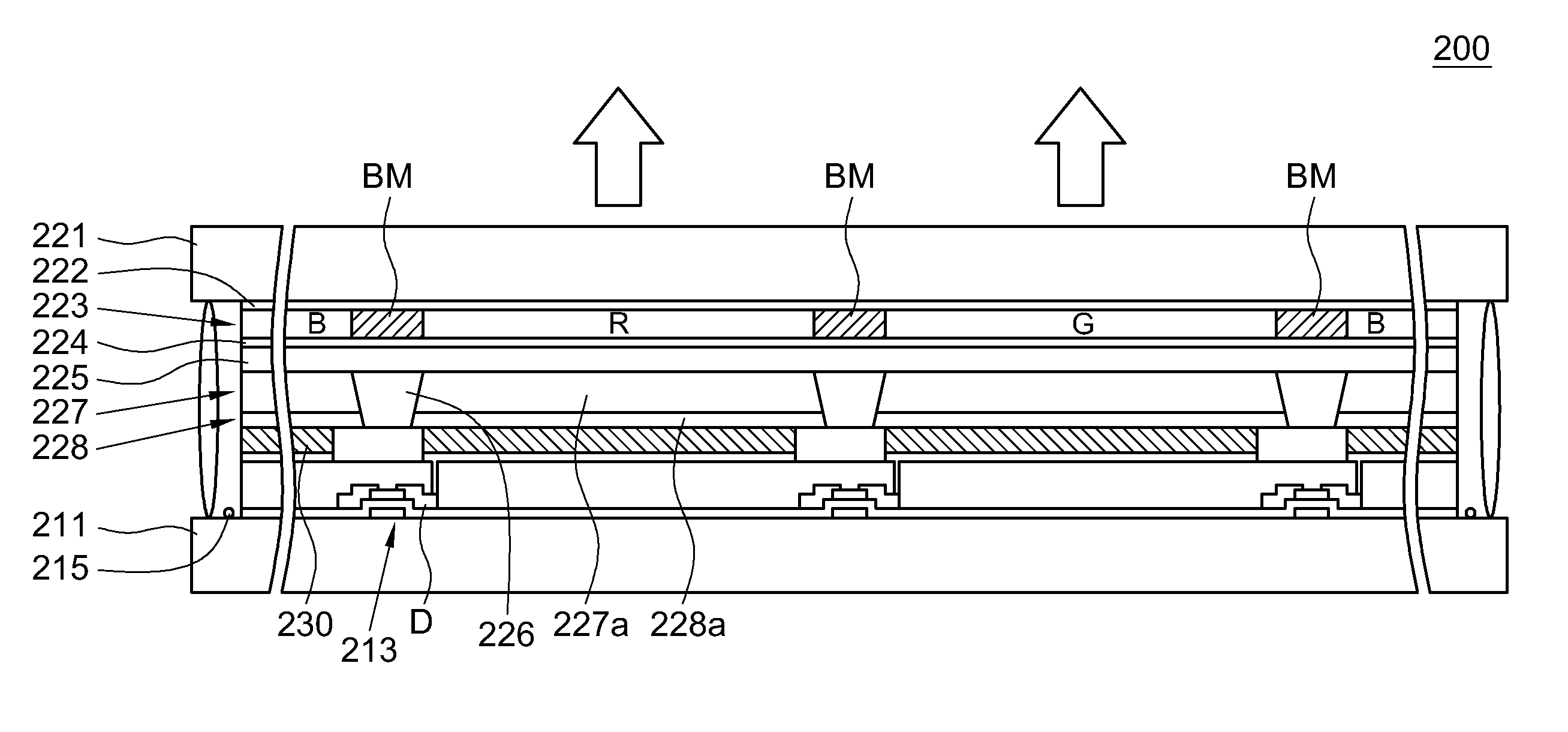

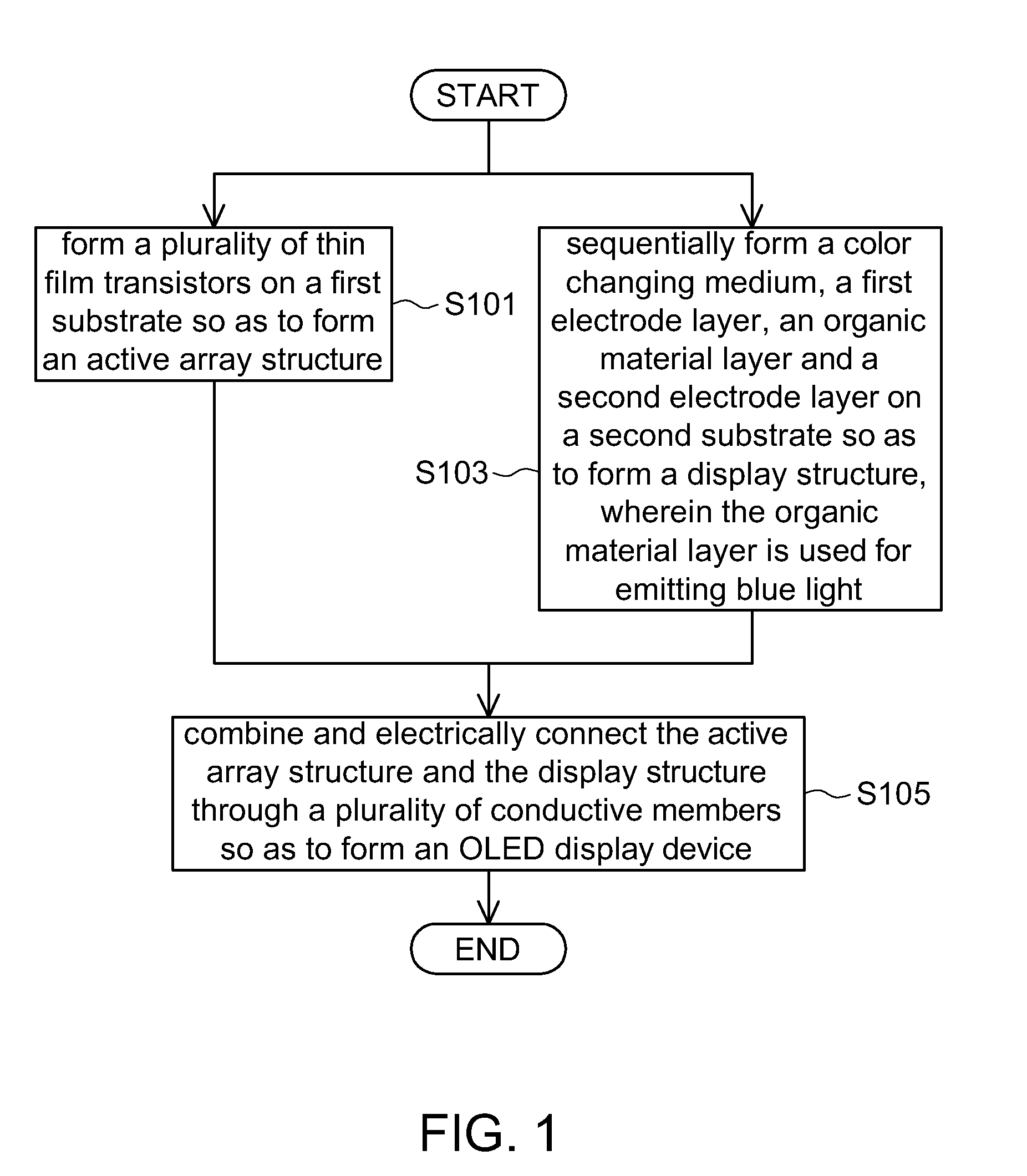

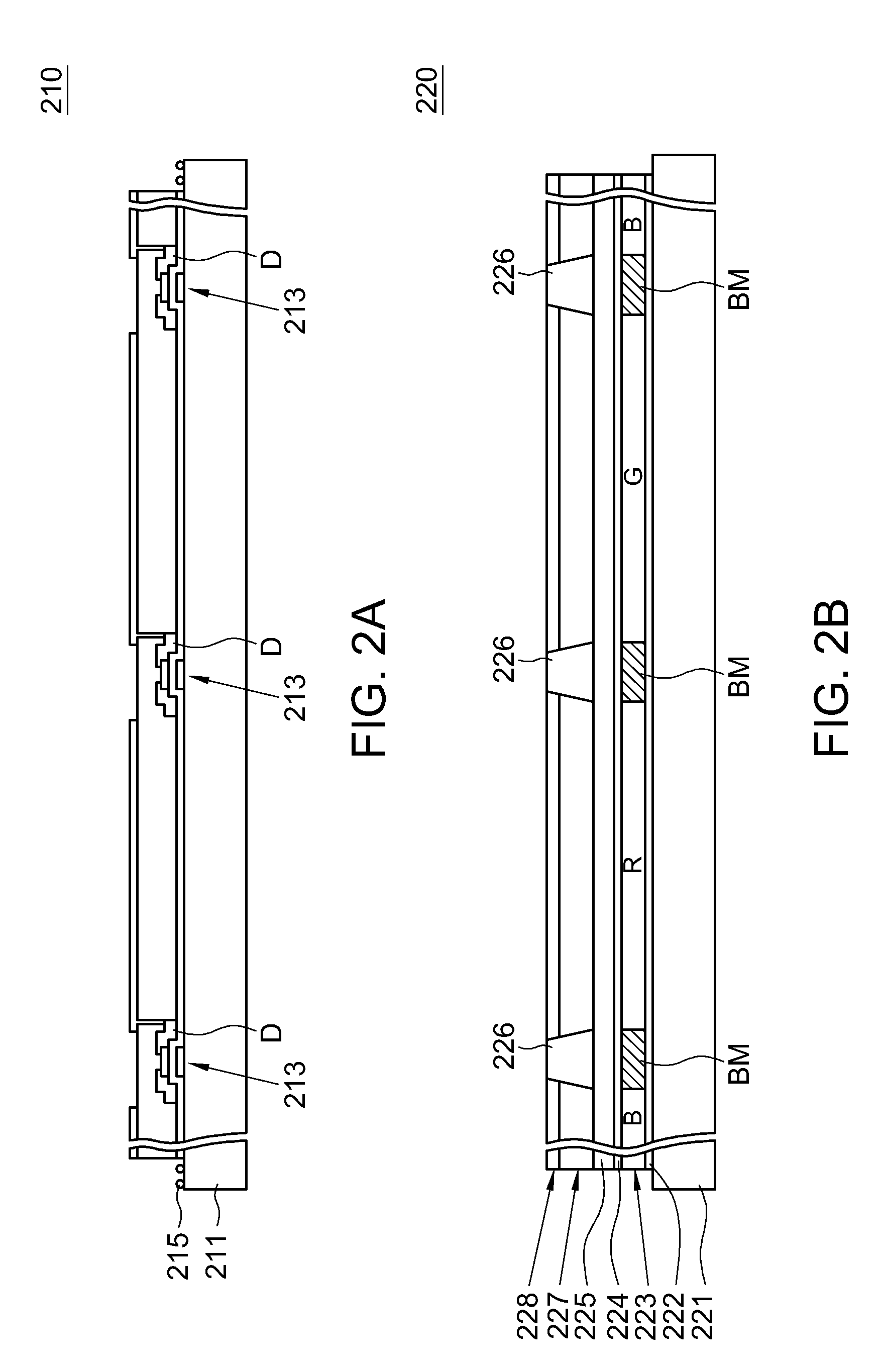

[0019]Referring to FIG. 1 and FIG. 2A, a flowchart of a manufacturing method of an OLED display device according to a preferred embodiment of the present invention is shown in FIG. 1, and a sectional view of an active array structure according to a preferred embodiment of the present invention is shown in FIG. 2A. In the step S101, several thin film transistors (TFT) 213 are formed on a surface of a first substrate 211 so as to form an active array structure 210. The thin film transistors 213 can be poly crystalline silicon thin film transistors, microcrystalline silicon thin film transistors or amorphous silicon thin film transistors.

[0020]Referring to FIG. 2B, a sectional view of a display structure according to a preferred embodiment of the present invention is shown. In the step S103, an auxiliary electrode 222, a color changing medium 223, a passivation layer 224, a first electrode layer 225, an organic material layer 227 and a second electrode layer 228 are sequentially formed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap