Optical semiconductor device, socket, and optical semiconductor unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

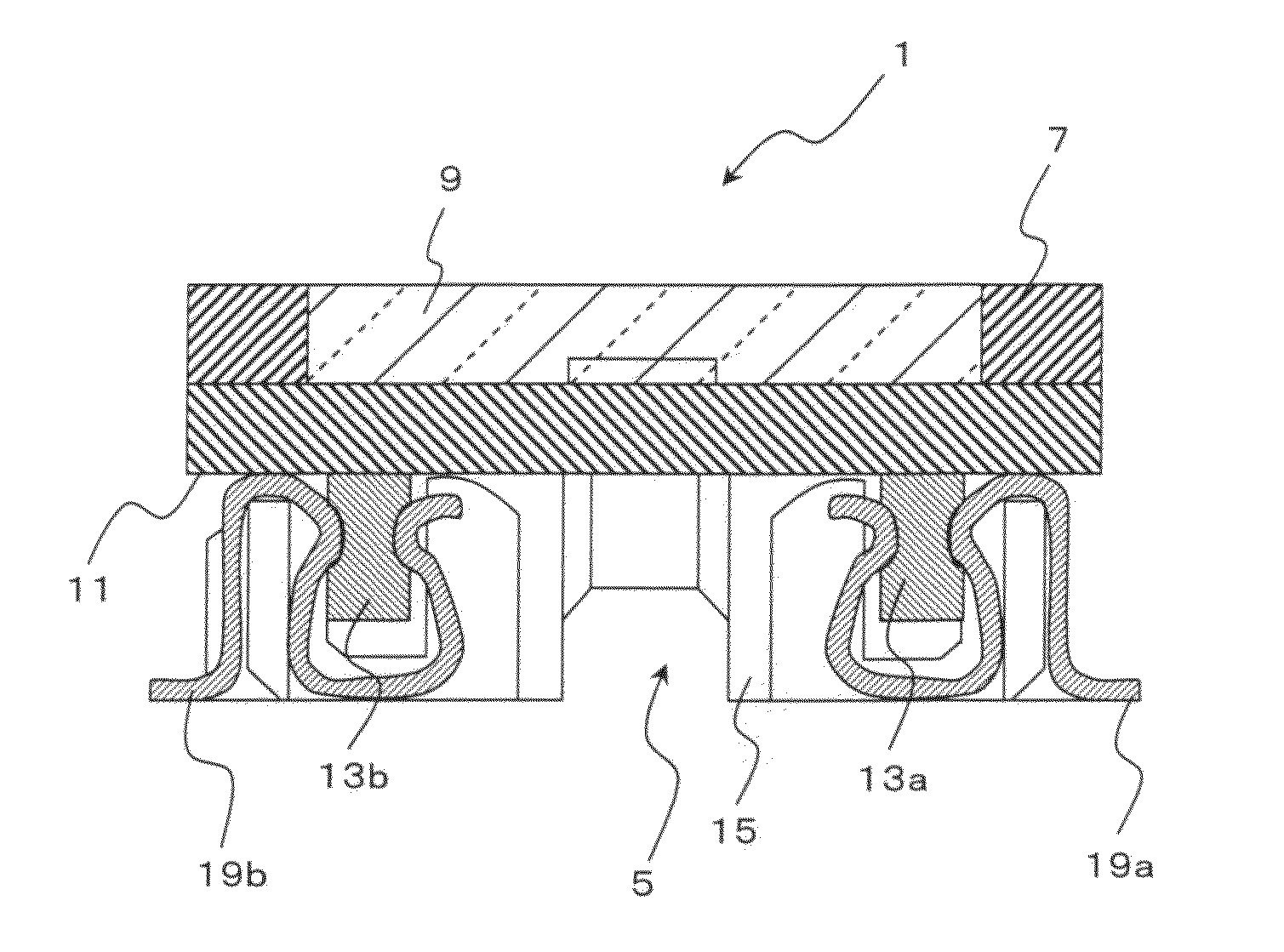

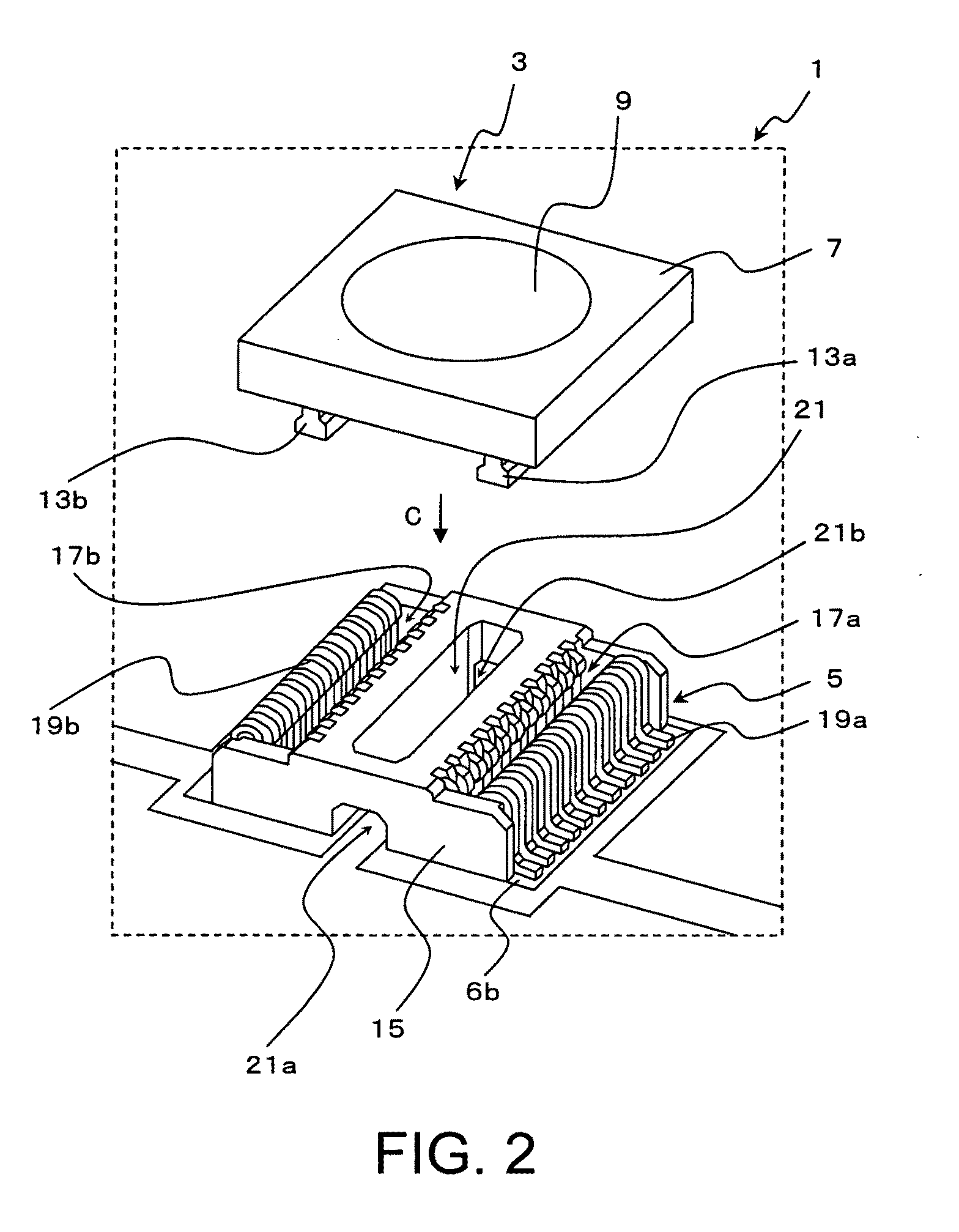

[0115]According to the design method using the finite element method described in the first embodiment, volumes of the main body 7 and the electrode portions 13a and 13b of the LED device 3 were calculated so as to optimize the thermal property data.

[0116]The LED 9 had a size of 1 mm square and a height of 0.1 mm. A thermal conductivity of the LED 9 and an input power supplied to the LED 9 were 42 W / mK and 1 W (at a room temperature), respectively.

[0117]A junction temperature of the LED 9 was 200° C. and the substrate 6a was a glass-epoxy substrate (FR-4) having a size of 50 mm square and a thickness of 0.8 mm.

[0118]As a material of the main body 7, Al2O3 (having a thermal conductivity of 18 W / mK) was used. As a material of the electrode portions 13a and 13b, oxygen-free copper (having a thermal conductivity of 390 W / mK) was used. Then, a relationship between a volume of the main body 7 and a temperature of the LED 9 and a relationship between a volume of the electrode portions 13a ...

example 2

[0122]According to the design method using the finite element method described in the first embodiment, comparison was made between junction temperatures of the LED 9 when the socket 5 according to the first embodiment was used and when the socket 5a according to the fourth embodiment was used.

[0123]Specifically, each of the eleven socket terminals 19a and the eleven socket terminals 19b of the socket 5 had a width of 0.2 mm and these socket terminals were disposed at a distance of 0.2 mm from one another. On the other hand, each of the four socket terminals 43a and the four socket terminals 43b of the socket 5a had a width of 0.91 mm and these socket terminals were disposed at a distance of 0.2 mm from one another. For all of those socket terminals, a contact length in a direction perpendicular to a width direction of each socket terminal was 0.92 mm.

[0124]As a material of the socket terminal, phosphor bronze (having a thermal conductivity of 63 W / mK) and a copper alloy (having a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com