Body Armor Suite Cooling System

a cooling system and body armor technology, applied in the field of body armor suite cooling system, can solve the problems of large power loss, difficulty in using the human body's evaporative cooling system, and loss of about 1 w of power, and achieve the effect of preventing any irritative and abrasive conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

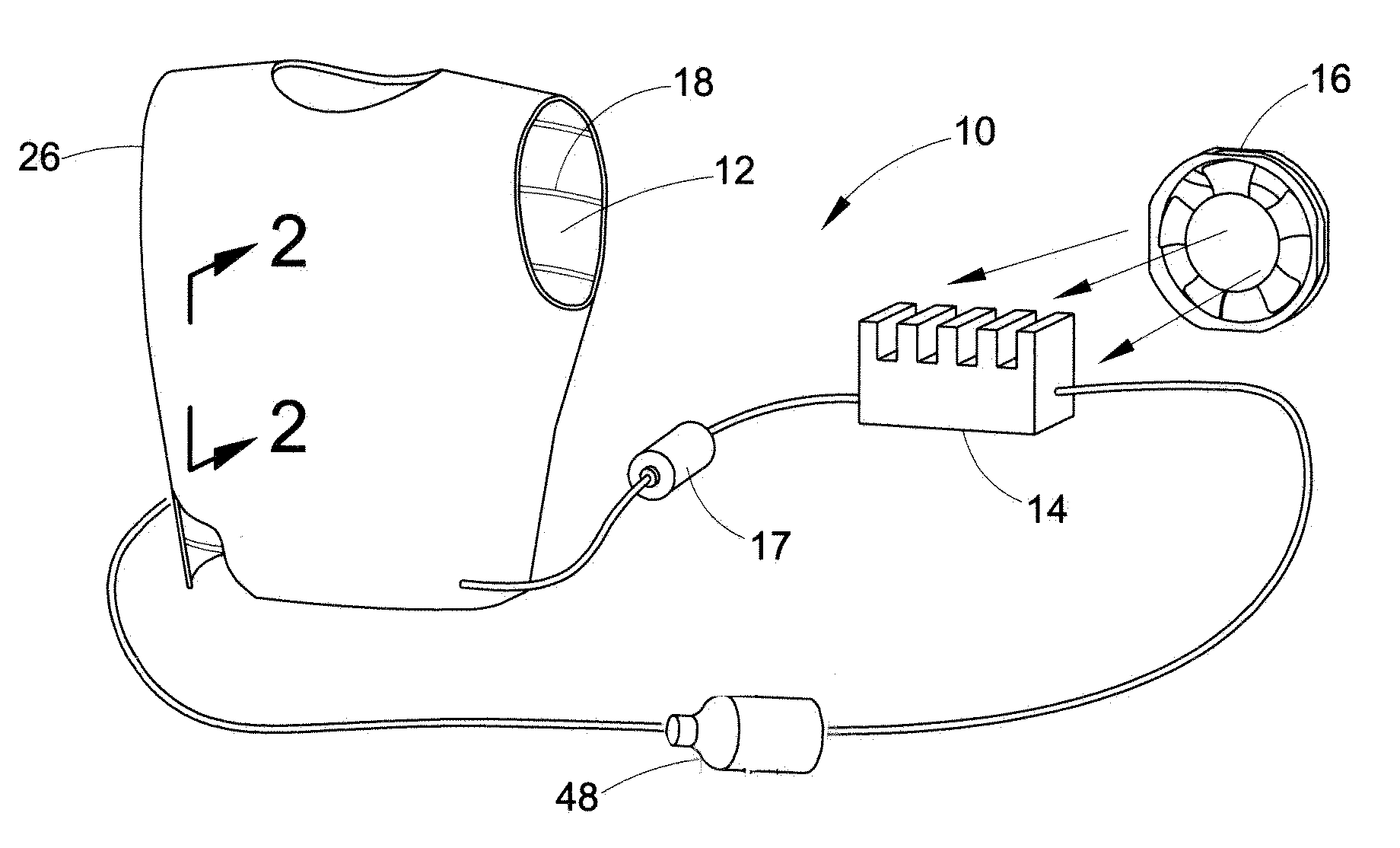

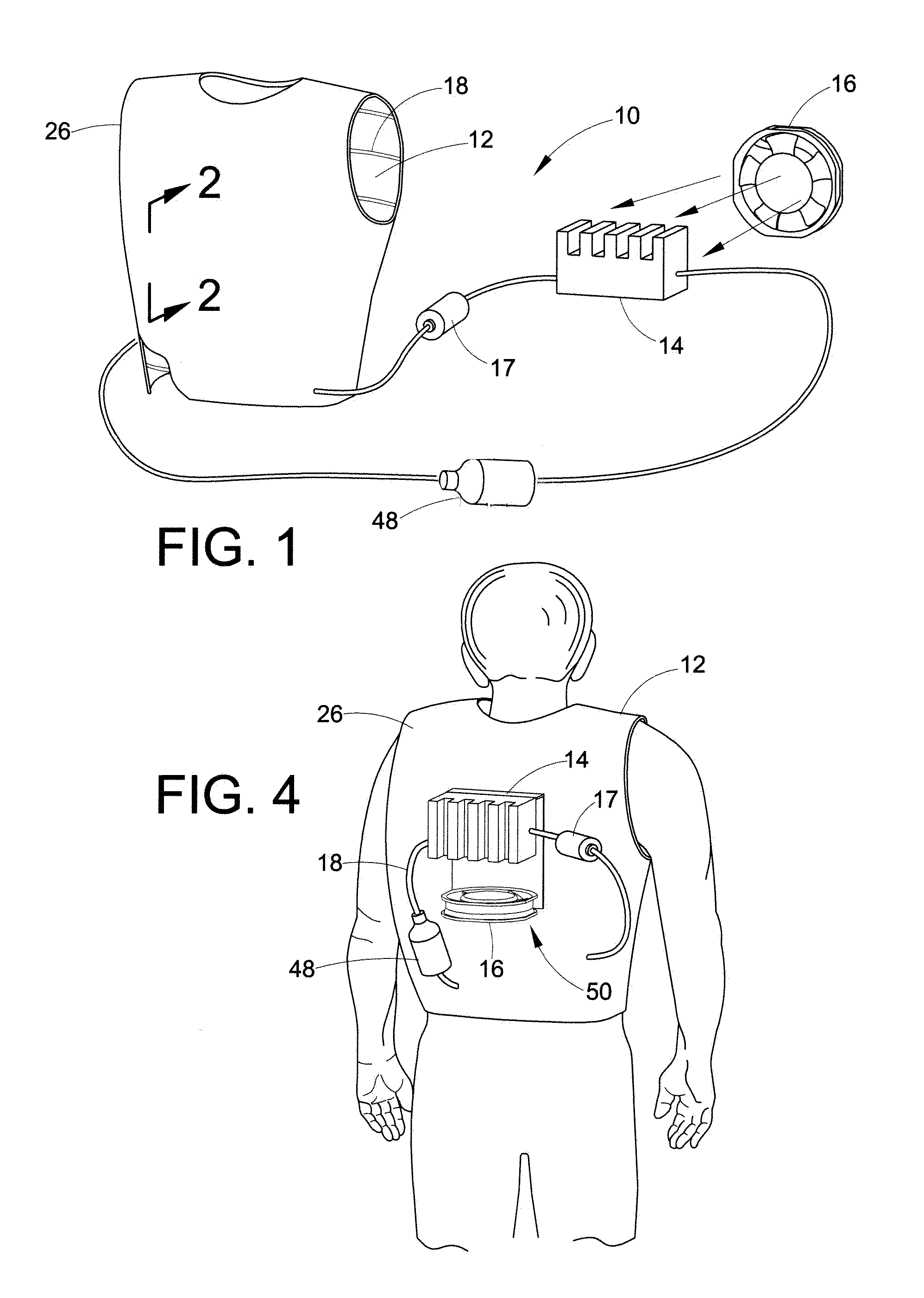

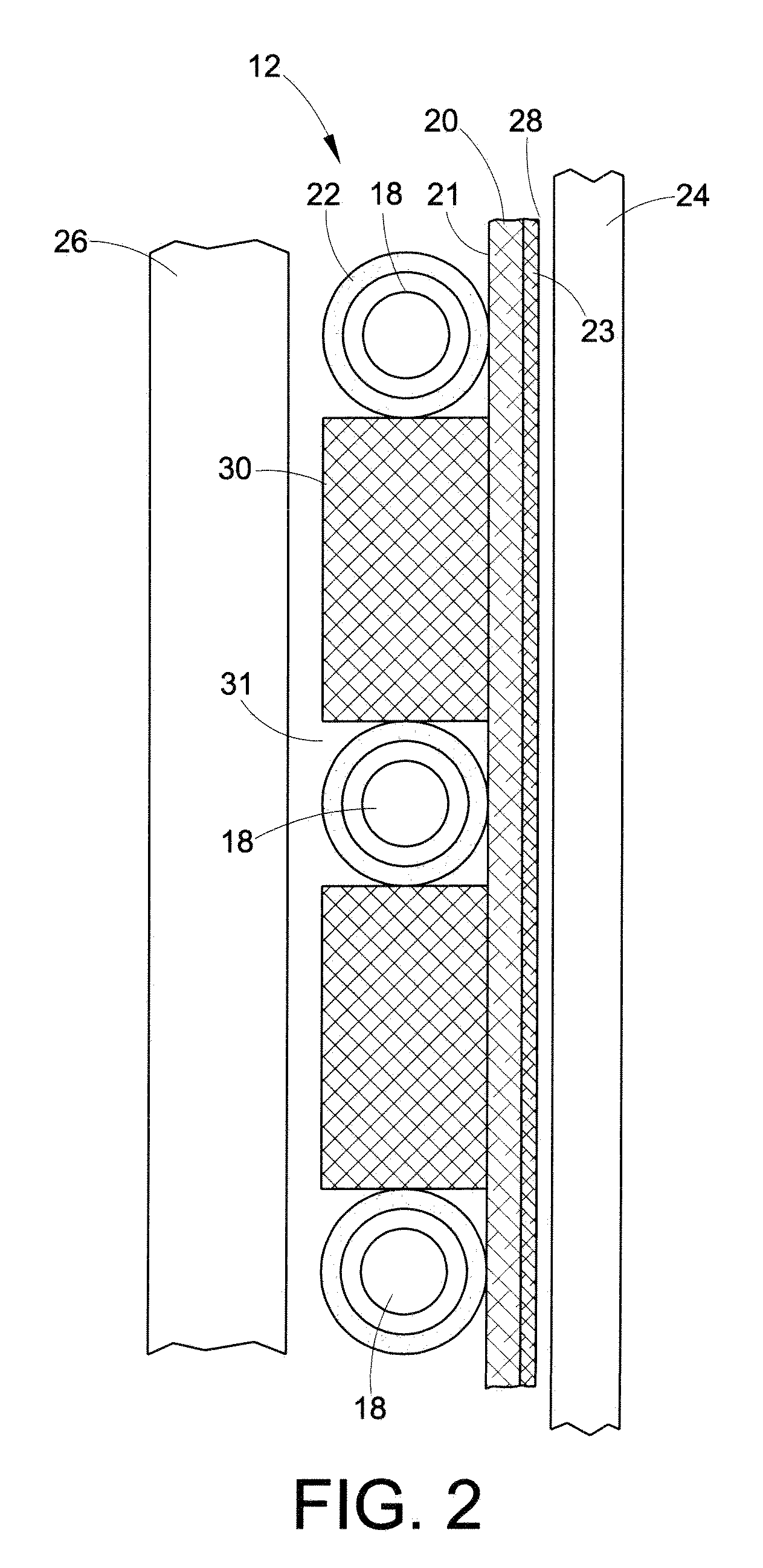

[0018]The present disclosure is directed to a body suit cooling system. Specifically, it is directed to a self-contained system worn by a person to maintain body temperature at healthy levels.

[0019]For purposes of this disclosure, the terms “body armor” and “suit” (hereinafter collectively referred to as “suit” or “protective suit”) refer to any protective clothing worn by a person. The present disclosure is particularly useful when used in conjunction with military suits and other armor worn by soldiers in combat; however, its use is not strictly limited to garments worn by servicemen. The term “suit” can similarly refer to explosive ordinance disposal (EOD) suits. The term “suit” can further include environmental suits designed for particular hostile environments. These suits can include any material which protects the wearer from certain temperatures, climates, or pressures. The term “suit” can also refer to a contamination or a hazardous material (“hazmat”) suit, which protects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com