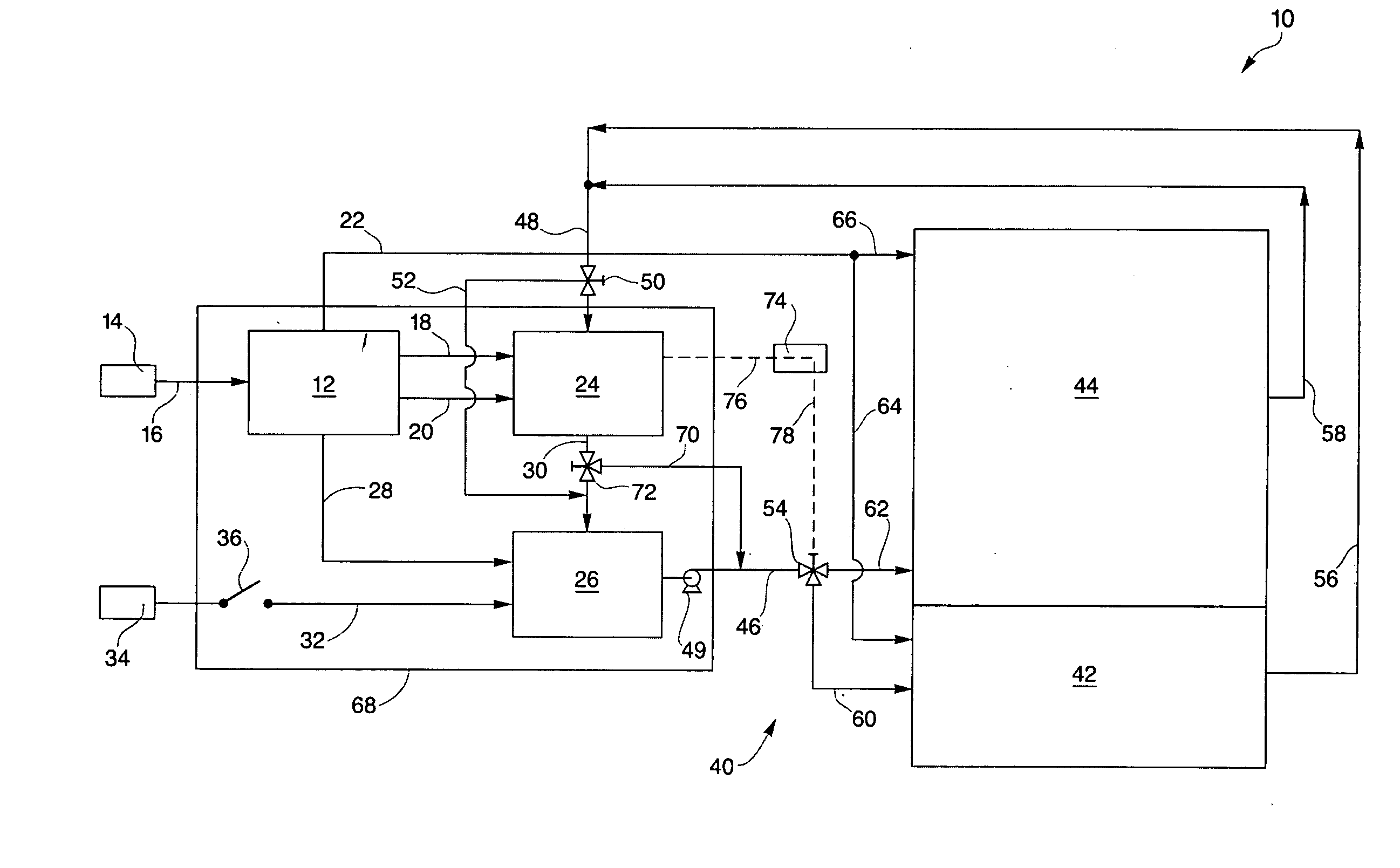

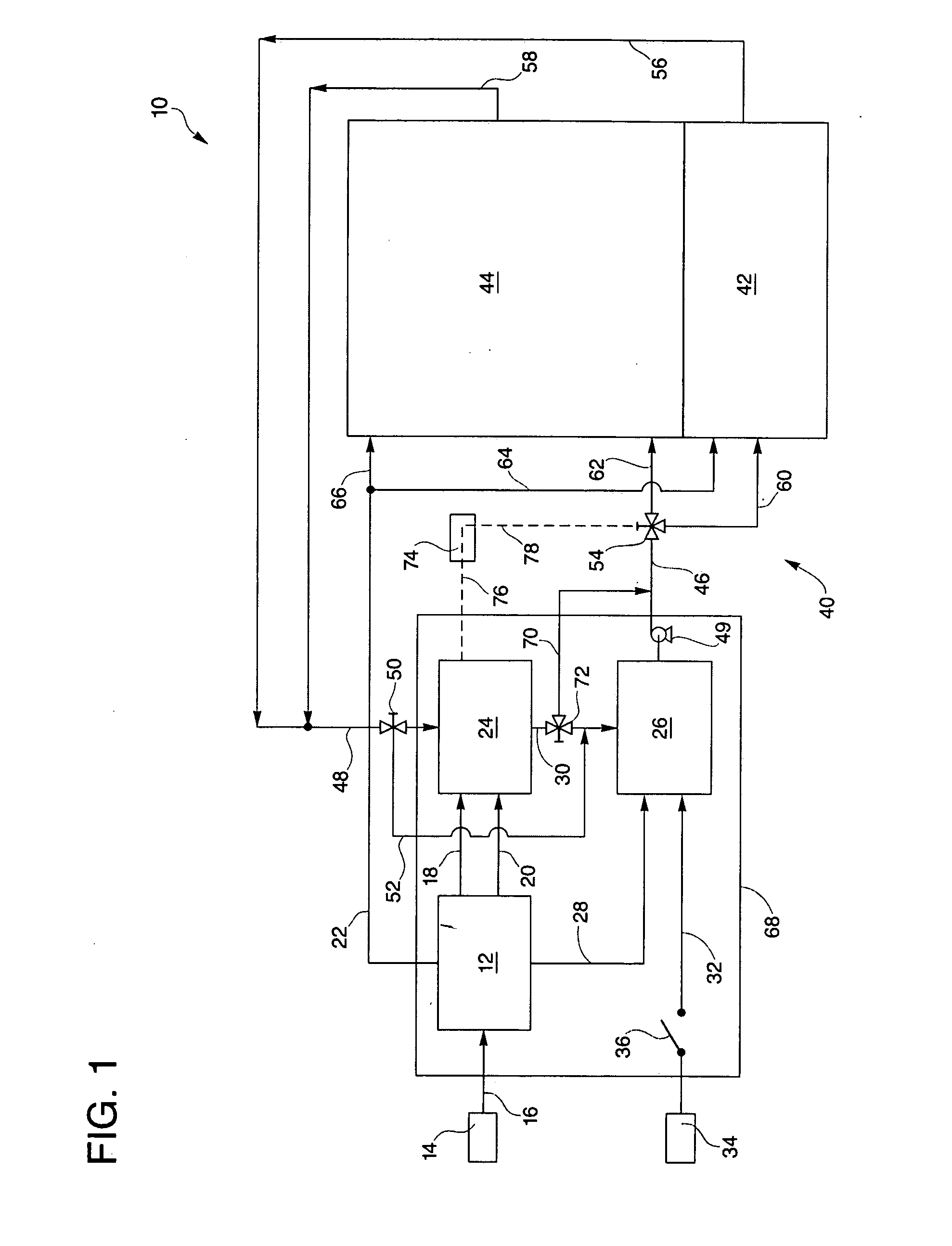

[0012]By integrating the part-load, active redundant chiller to operate downstream from the absorption chiller so that it receives the cooling-heating fluid after it has been cooled by the absorption chiller, the part-load, active redundant chiller may operate at a very

high rate of efficiency compared to the part-load, active, redundant chiller operating alone to achieve a required decrease in temperature of the cooling-heating fluid. For example, if the circulating cooling-heating fluid must be reduced in temperature by a total of 10 degrees by the cooling, heating and power system, and the absorption chiller first reduces the temperature by 5 degrees, the part-load, active, redundant chiller can be sized to reduce the cooling-heating fluid the additional 5 degrees while operating at between about 40% to about 60% of its capacity or “load”, which is a highest efficiency

operating point of the part-load, active, redundant chiller. (For purposes herein, the word “about” is to mean plus or minus 10%.) This permits the part-load, active, redundant chiller to operate at a very

high rate of efficiency by reducing mechanical work required by the part-load, active, redundant chiller. Then, if operation of the absorption chiller is interrupted, the part-load, active, redundant chiller may be controlled to operate at about one-hundred percent load to satisfy the cooling demands of the

critical zone. More importantly, during normal operation of the system, by having the electrically powered part-load, active, redundant chiller operate downstream from the absorption chiller, both chillers may be sized for minimal cost and maximum operating efficiency to thereby deliver cooling to the multi-zone cooling-heating circuit at a very low kilowatt per

refrigeration ton (“kW /

ton”) value, while providing enhanced cooling

backup. In a preferred embodiment, the part-load, active, redundant chiller is a high efficiency, tri-screw electric chiller.

[0013]Integrating the part-load, active, redundant chiller downstream from the absorption chiller also permits efficient

sizing of the absorption chiller so that the absorption chiller does not have to be substantially over sized beyond

normal load conditions to meet peak loads described above. Instead, the part-load, active, redundant chiller is dimensioned to be responsive to normal loads on the system while operating at between about 40% to about 60% load, and during

peak load conditions, the part-load, active, redundant chiller is controlled to increase

cooling capacity to meet the

peak load conditions. If operation of the absorption chiller is interrupted producing offnormal load conditions, the part-load, active, redundant chiller may be controlled to increase its

cooling capacity from the efficient 40% to 60% load to a load between about 60% and 100% to meet the offnormal condition. Integration of the part-load, active, redundant chiller with the absorption chiller and prime mover therefore provides enormous efficiencies in manufacture, cost and operation of the cooling, heating and power system of the present disclosure.

[0015]By integrating the part-load, active, redundant chiller with the prime mover and the absorption chiller, in the event operation of the absorption chiller is interrupted, the cooling-heating fluid would continue to flow into the part-load, active, redundant chiller to be chilled, and the circuit control valve would be controlled to direct the cooling-heating fluid from the part-load, active, redundant chiller only into the critical zone of the multi-zone cooling-heating circuit. Alternatively, the circuit control valve would be controlled to direct as much of the cooling-heating fluid into the critical zone as is necessary to satisfy cooling needs of the critical zone, while the remaining fluid is directed into the utility zone. The multi-zone cooling-heating circuit directs the cooling-heating fluid back from the critical zone and optionally some fluid from the utility zone through the circuit return line into either the non-operational absorption chiller to flow through the absorption chiller, or through an absorption chiller by-pass line directly into the part-load, active, redundant chiller to be cooled again and to continue circulating through the critical zone. Use of the part-load, active, redundant chiller, therefore minimizes any need for any further cooling

backup for the critical zone while the absorption chiller is being repaired, replaced, etc.

[0017]A primary use of the cooling, heating and power system with an integrated part-load, active, redundant chiller is to substantially decrease overall cooling costs as well as to supplement, secure and backup the cooling, heating and power requirements of a structure, such as a building having a critical zone and a utility zone. It is to be understood that the present disclosure may also be utilized as a stand alone cooling, heating and power system without parallel electricity supplied by the grid, such as to be the primary cooling, heating and power system for an

oil drilling platform or for similar stand alone usages. The cooling, heating and power system of the present disclosure also provides the above described advantages in such usages.

[0019]It is a more specific purpose to provide a cooling, heating and power system with an integrated part-load, active, redundant chiller that increases operating efficiencies of the system and decreases manufacture, installation and

operational costs of the system.

Login to View More

Login to View More  Login to View More

Login to View More