Method of carbon chain extension using novel aldol reaction

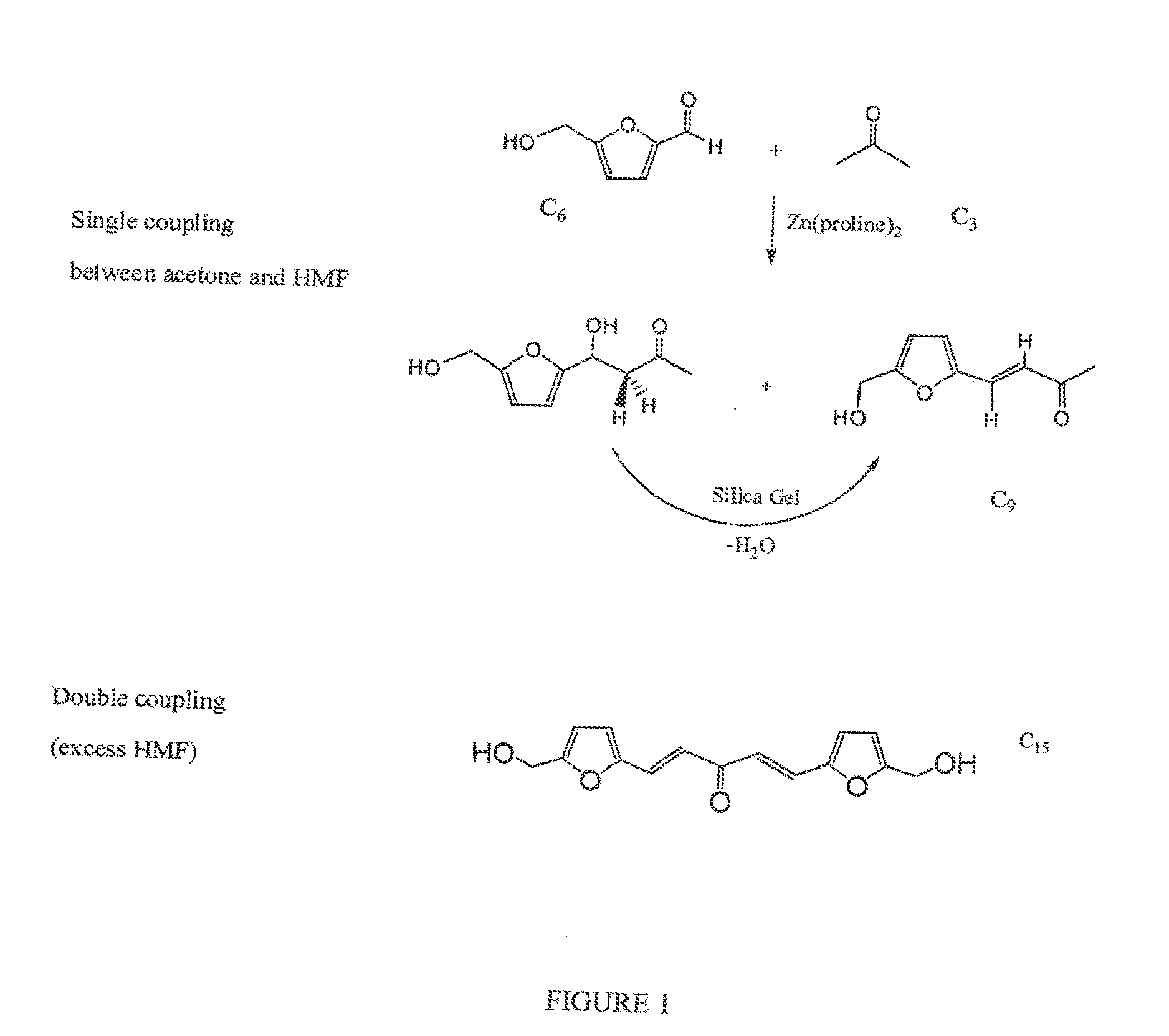

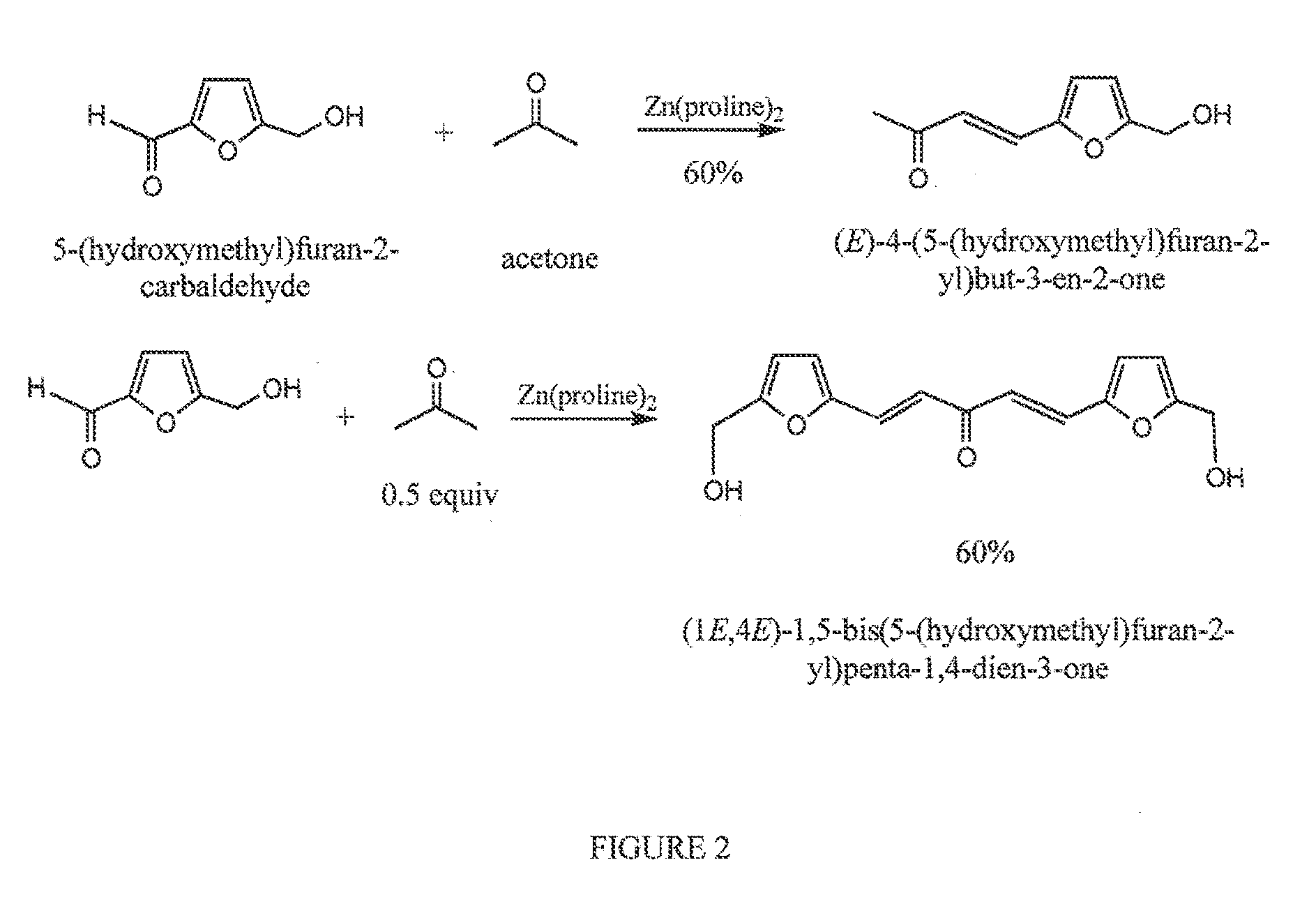

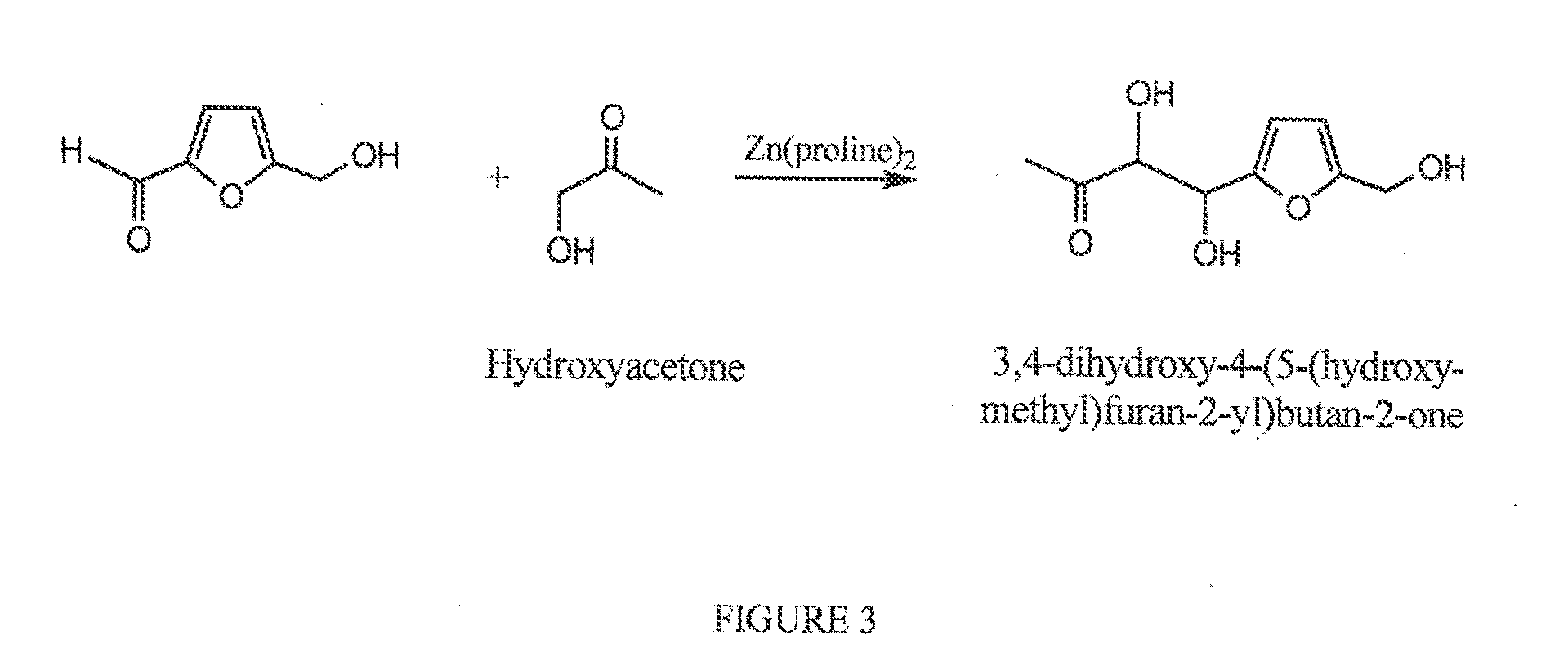

a technology of aldol and carbon chain, which is applied in the field of carbon chain extension using novel aldol reaction, can solve the problems of poor selectivity, process less suitable for large-scale industrial use, and zinc-proline catalysts have shown only to successfully catalyze, and achieves high specificity and increase the length of carbon chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025]The reactions were performed in water without adjustment of pH. Piperidine was used in 5 mol %. HMF (0.631 g, 5.00 mmol) was charged in a small round bottom flask with a stirring bar, water (4.0 mL) was added. Acetone (0.290 g, 5.00 mmol (1 equivalent) or 0.25 mmol (0.5 equivalent) was then added. The mixture was then stirred while piperidine was added at room temperature. The reaction mixture was kept closed with a plastic cap and stirred for 20 hrs. The stirring bar was removed and silica gel was added. The mixture was dried with rotary evaporation. The residue was loaded on silica gel and eluted with 50% ethyl acetate in hexanes to provide mono-HMF adduct (0.191 g, 23%) as a light yellow solid. 1H NMR (CDCl3) δ 7.16 (d, J=16.0 Hz), 6.55 (d, J=3.45 Hz), 6.51 (d, J=16.0 Hz), 6.32 (d, J=3.40 Hz), 4.57 (s), 2.23 (s). 13C NMR (CDCl3) δ 198.6, 157.5, 150.6, 129.8, 123.9, 117.1, 110.5, 57.4, 27.9. And di-WAY adduct (0.469 g, 68%) as a dark reddish solid. 1H NMR (CDCl3) δ 7.43 (d, ...

example 2

[0026]In a 100 mL single-necked round bottom flask was placed HOBT (hydroxybenzotriazole) (1.95 g), L-Boc-proline (3.00 g), and 2-hydroxy-2-methyl-propyl-1-amine. To this was added 70 mL of anhydrous acetonitrile. This was stirred until homogenous and then chilled to 0° C. The EDC (1-ethyl-3-(3-dimethylaminopropyl)carbodiimide), (3.20 g) was added in one portion to this mixture. The mixture was allowed to warm to room temperature and stirred overnight. The solvent was removed in vacuo. The remaining material was then taken up in 60 mL of methylene chloride and subsequently washed 4× with 10 mL of 5% citric acid. The suspension was filtered and dried over sodium sulfate. Filtration and removal of the solvent gave rise to the crude material. Purification by silica gel chromatography using 10% methanol / methylene chloride as eluent afforded 3.0336 g of an amide having the structure (IV), tert-butyl 2-(2-hydroxy-2-methylpropylcarbamoyl)pyrrolidine-1-carboxylate. 1H NMR (CDCl3) d 4.29 (J=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com