Bleach Safe, Stain Free, Quick Drying Drylon Rugs

a technology of drylon rugs and which is applied in the field of dyeing safe, stain-free, and quick drying drylon rugs, can solve the problems of affecting the use of dope dyed micro-denier filaments, affecting the effect of dyeing, and affecting the color of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

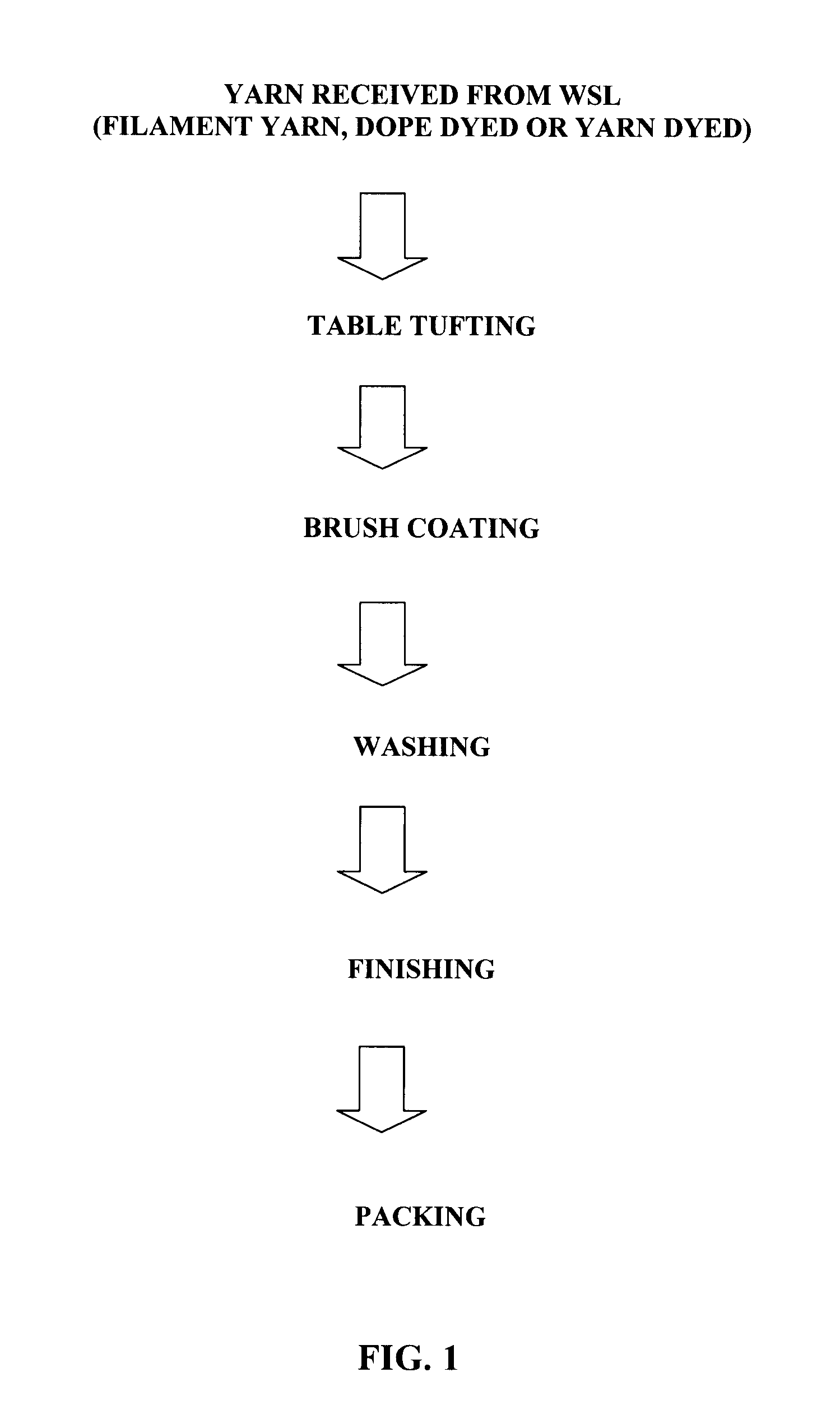

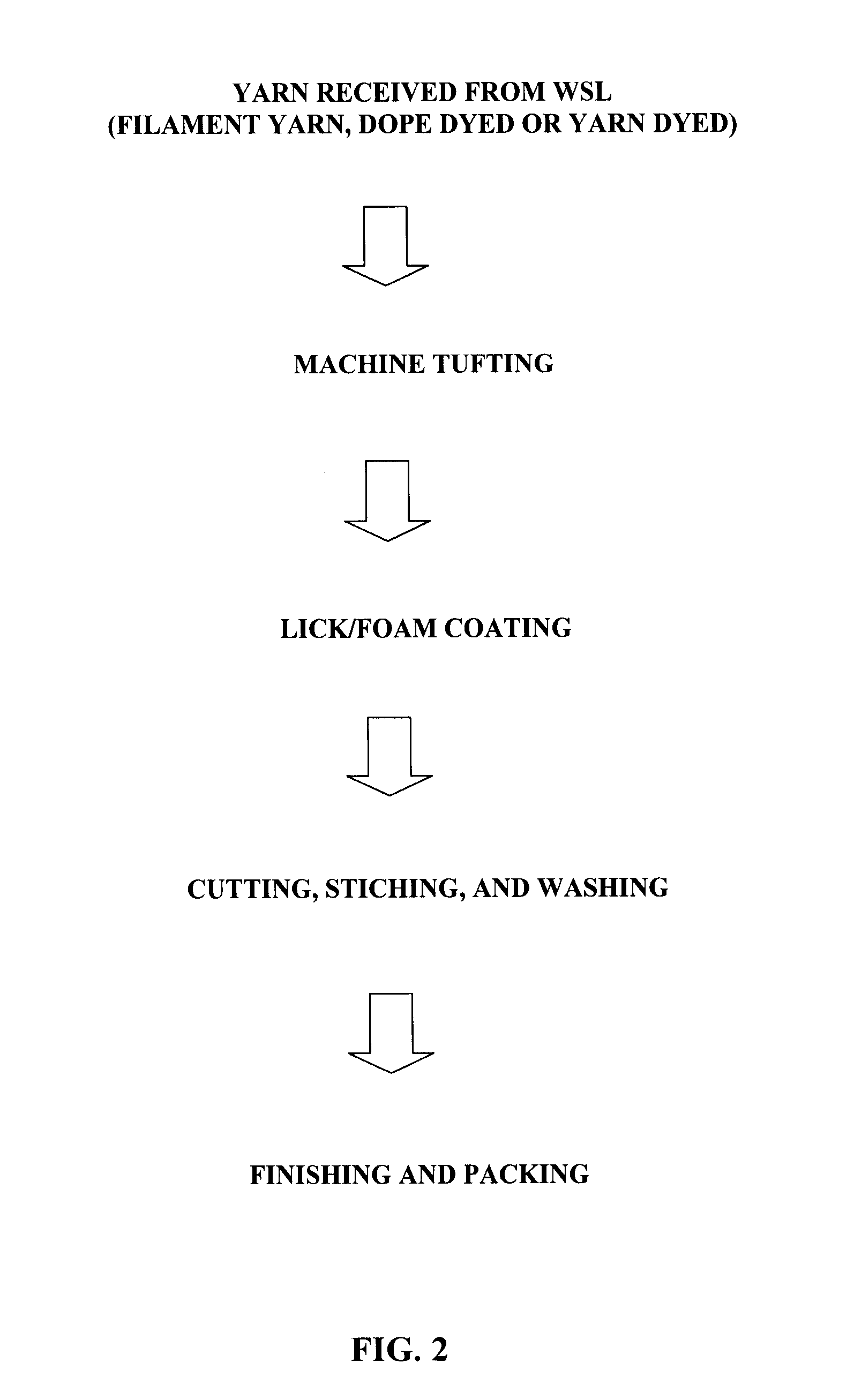

Method used

Image

Examples

example 1

[0051]A DRYLON rug made of DRYLON yarn which has properties of bleach fastness, stain resistance and quick drying. The DRYLON tufting yarn is B. S. Blue colored, dope dyed 1.0 micro denier per filament fiber, which is further twisted with 900×2, micro filament to form 1800 (900×2) denier tufting yarn.

[0052]The process for making the rug of instant invention comprises of tufting of 1.0 DPF×900><2 B. S. blue dope dyed filament, creeled on 1280 cheeses to form tufted fabric roll. The tufted rolls are further loaded on latex coating machine followed by application of latex at 20.0 Oz / sq. yard or 687 GSM to form a rug fabric. The latex coated tuft rolls are cut on infra-red guided cutting machine as per pre-determined specification fed in the computer to form rugs. Lastly the rugs are stitched on four sides on a stitching machine and finally, the stitched rugs are then, washed, checked, mended folded, passed through needle detectors and packed in to poly bags before packing in to cartons...

example 2

[0055]The following Table 2 details the physical and chemical properties of DRYLON yarn of 1.0 to 10.0 denier per filament.

TABLE 2Thermal propertiesSp. HeatKJ / kg ° k1.1--1.4Tg° c.70-80Tm° c.260Heat setting° c.180-230Dyeing temperature° c.120-180MoistureAt 21° c. / 65% RH%0.2-0.524° c. / 95% RH%0.8-1.0Water retention% 3-5.ShrinkageIn water 95° C.%0.5-8 Hot air 150° C.% 2-15.Hot air 190° C.% 3-20.Degree of elasticityAt E = 22%90-98E = 25%70-90E = 10%50-80Densitygm / cm31.36--1.38R. I.1.54LOI index%21--22FinenessDPF 1-10.Cable denier1800-2400Elongation%20-45TenacityGMF / Den2.8-3.6Cross sectionCircular & trilobalCable twist per meter 70-200Resistance to:AcidGood, attacked by concentrationacidsAlkaliGood, degradable by concentrationalkaliBacteria & fungusVery goodDye stuffDispersion with carrier at high tempSolubilitySulfuric acid, tetrachloro ethanephenol, dmf, teg

example 3

[0056]A DRYLON rug made of DRYLON yarn which has properties of bleach fastness, stain resistance and quick drying. The DRYLON tufting yarn is yarn dyed in W. Denim shade, consisting of 1.0 micro denier per filament fiber, which is further twisted with 900×2, micro filament to form 1800 (900×2) denier tufting yarn and dyed.

[0057]Dyeing process for yarn dyeing is as below in Table 3. Dyeing of 1800 / 180 tpm and 1800 / 100 tpm of Semi Dull and Bright luster yarn. The dyeing is done at 132° C. and the rate of raising temperature is not more than 1.0° C. / min.

TABLE 3StepsDetailsSetting DyebathSet Machine with water at 50° C. to 60° C.Adding ChemicalsAdd dispersing agent 0.5 TO 1 GPLAdd leveling agent 0.5 TO 1 GPLAdjust the pH to 4.5 TO 5 with buffer.Adding DyesAdd sieved dispersion dyesRaising temp.Raise the temperature up to 132° C.Continue DyeingAt 132° C. hold 30 minute.Then drain at 132° C.Reduction ClearingReduction clearing with: Caustic soda and Sodium hydrosulfiteFor optimum fastness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| heights | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com