Pregreg, film with resin, metal foil with resin, metal-clad laminate, and printed wiring board

a technology of metal foil and resin, which is applied in the direction of synthetic resin layered products, solid-state devices, metallic pattern materials, etc., can solve the problems of resin compositions with inferior ion migration resistance and insulating reliability, and the demand is concomitantly increasing, so as to achieve excellent insulating reliability, excellent bending resistance, and excellent bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

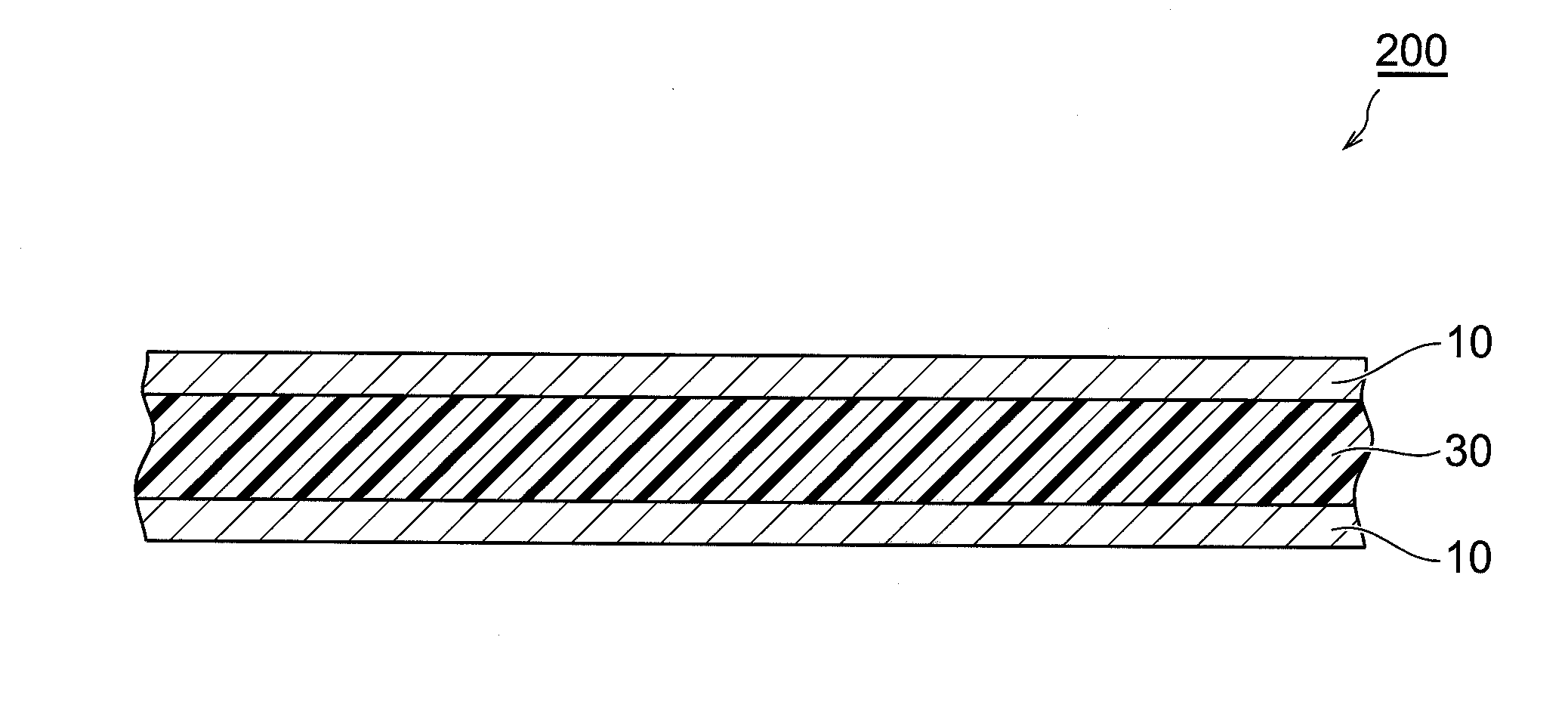

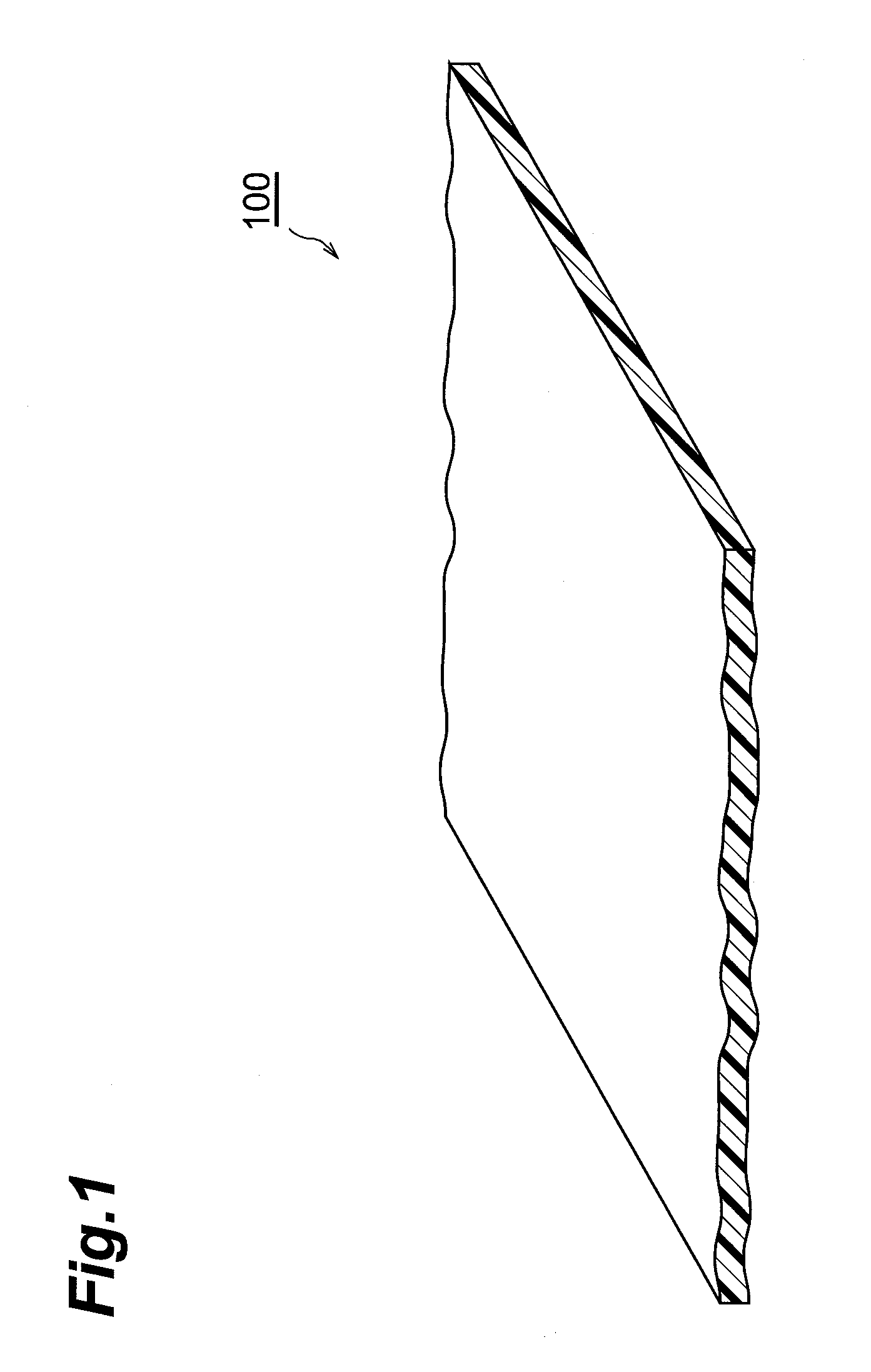

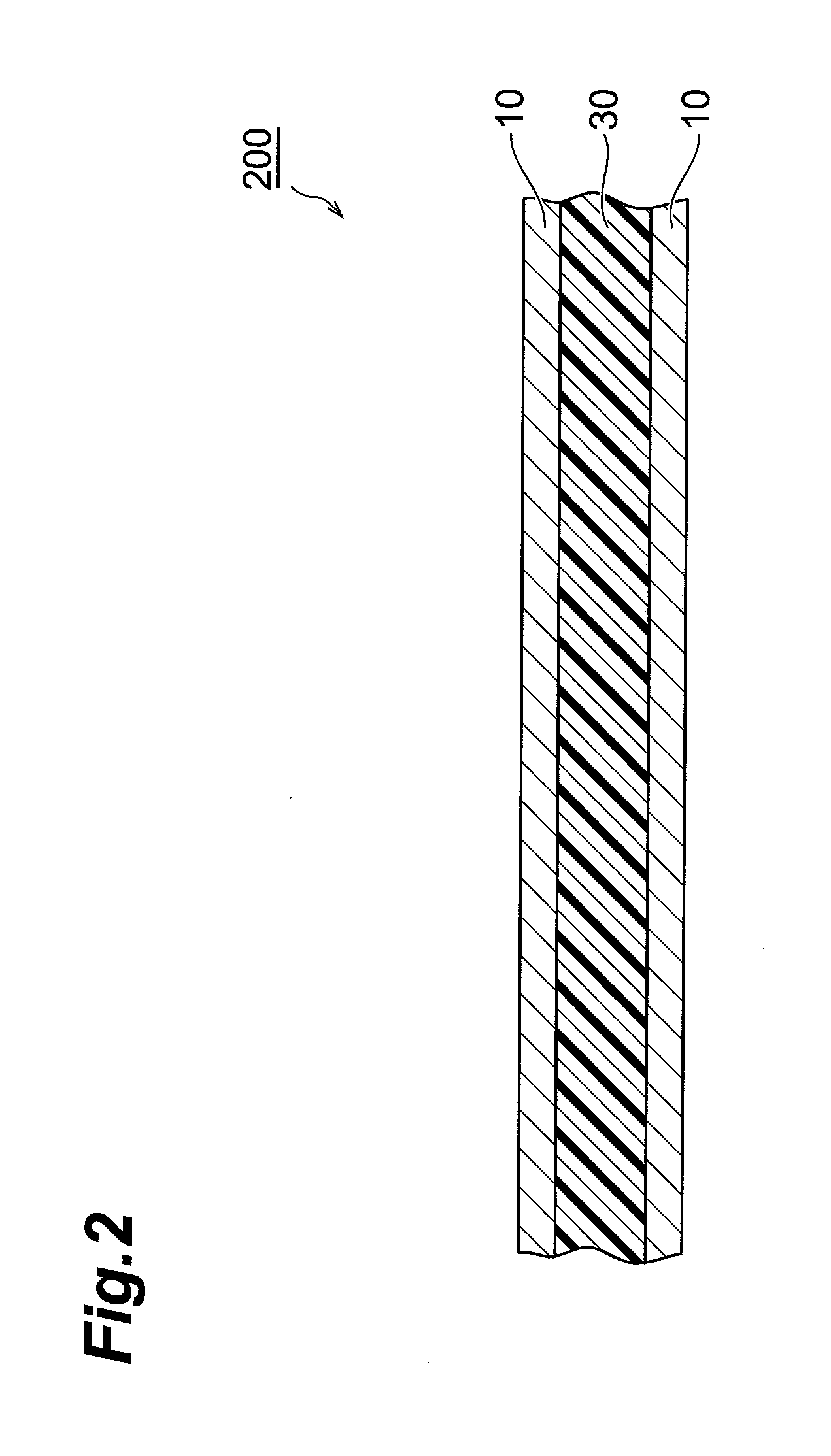

Image

Examples

example 1

[0079]295 g of tricyclo[5.2.1.02,6]deca-8-yl acrylate (product of Hitachi Chemical Co., Ltd., FA-513AS, see formula (A) below), 288 g of ethyl acrylate (EA), 387 g of n-butyl acrylate (BA) and 30 g of glycidyl methacrylate (GMA) are mixed to obtain monomer mixture A. To the obtained mixture A, 2 g of lauroyl peroxide and 0.16 g of n-octylmercaptane were further dissolved, to obtain monomer mixture B.

[R═H; product name: FA-513AS, R═CH3; product name: FA-513MS]

[0080]Into a 5 L autoclave equipped with a stirrer and condenser there were added 0.04 g of polyvinyl alcohol as a suspending agent and 2000 g of ion-exchanged water, and then monomer mixture B was added while stirring and the mixture was stirred at 250 rpm under a nitrogen atmosphere, at 60° C. for 2 hours, and polymerization was conducted at 100° C. for 1 hour to obtain resin particles (polymerization rate: 99% by weighing). The resin particles were rinsed, dehydrated and dried and then dissolved in methyl isobutyl ketone to a...

examples 2-12 , examples 22-34

Examples 2-12, Examples 22-34 and Comparative Examples 1-3

[0082]Thermosetting resin varnishes were prepared in the same manner as Example 1, except for using monomer mixtures A having the compositional ratios listed in Tables 2-8.

example 13

[0083]A thermosetting resin varnish was prepared in the same manner as Example 1, except that acrylic resin B prepared by the method described below was used instead of acrylic resin A.

In a 1 L-volume flask there were placed 285 g of tricyclo[5.2.1.02,6]deca-8-yl acrylate (FA-513AS, product of Hitachi Chemical Co., Ltd.), 280 g of ethyl acrylate (EA), 385 g of n-butyl acrylate (BA), 50 g of glycidyl methacrylate (GMA), 400 g of methyl isobutyl ketone and 0.1 g of azobisisobutyronitrile, and the components were mixed for 60 minutes under a nitrogen atmosphere. The mixture was then heated at 80° C. for 30 minutes, and polymerization was conducted for 3 hours to synthesize acrylic resin B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com