Lecithin carrier vesicles and methods of making the same

a technology of lecithin carrier and vesicles, which is applied in the field of lecithin carrier compositions and methods of making lecithin carrier compositions, can solve the problems of unfavorable active ingredient dispersion, so as to reduce the size of the membrane loaded lecithin vesicles and achieve high shear mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1-1

HLCV Dispersion of Fish Oil (Omega-3 Formulations)

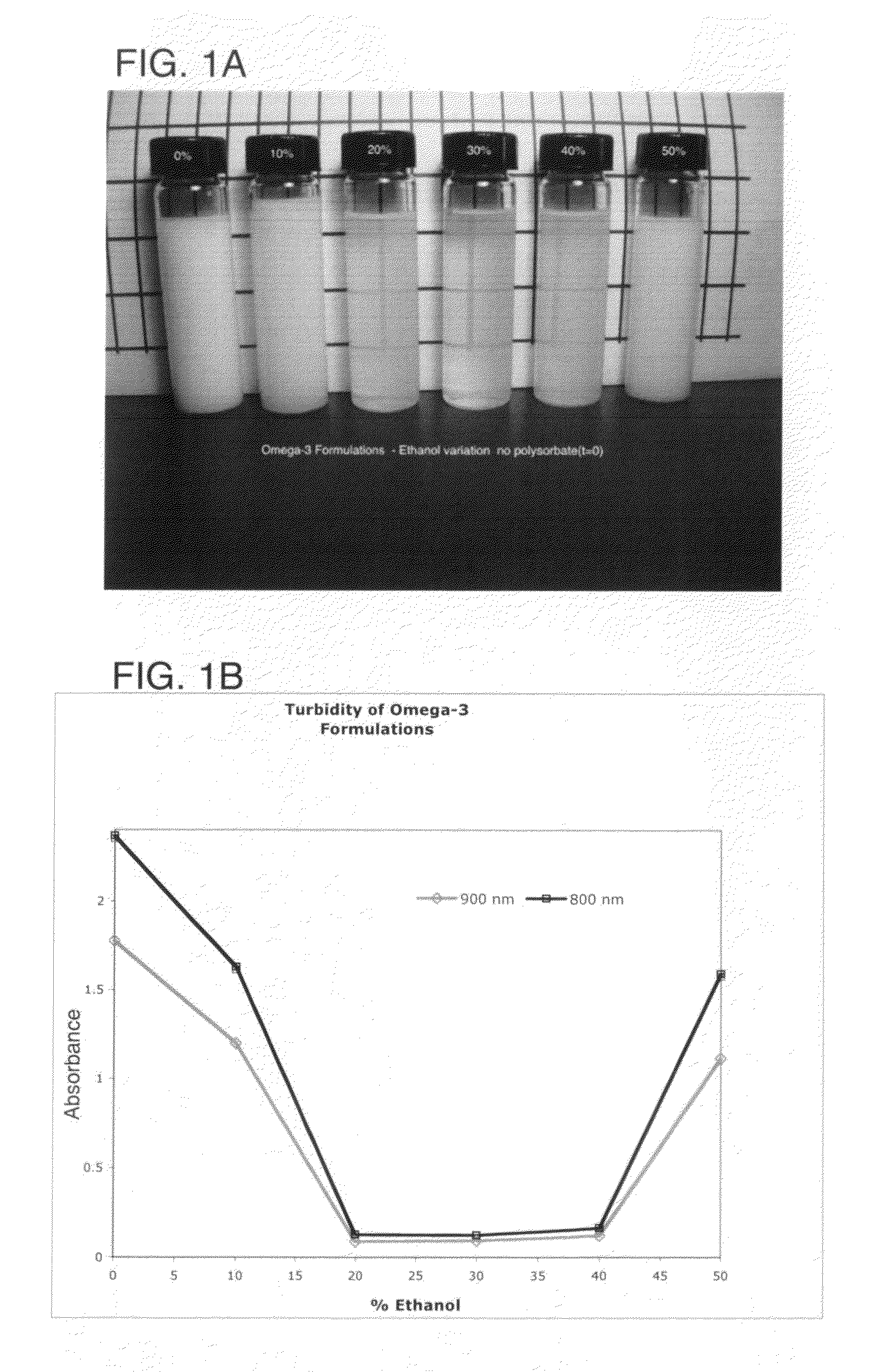

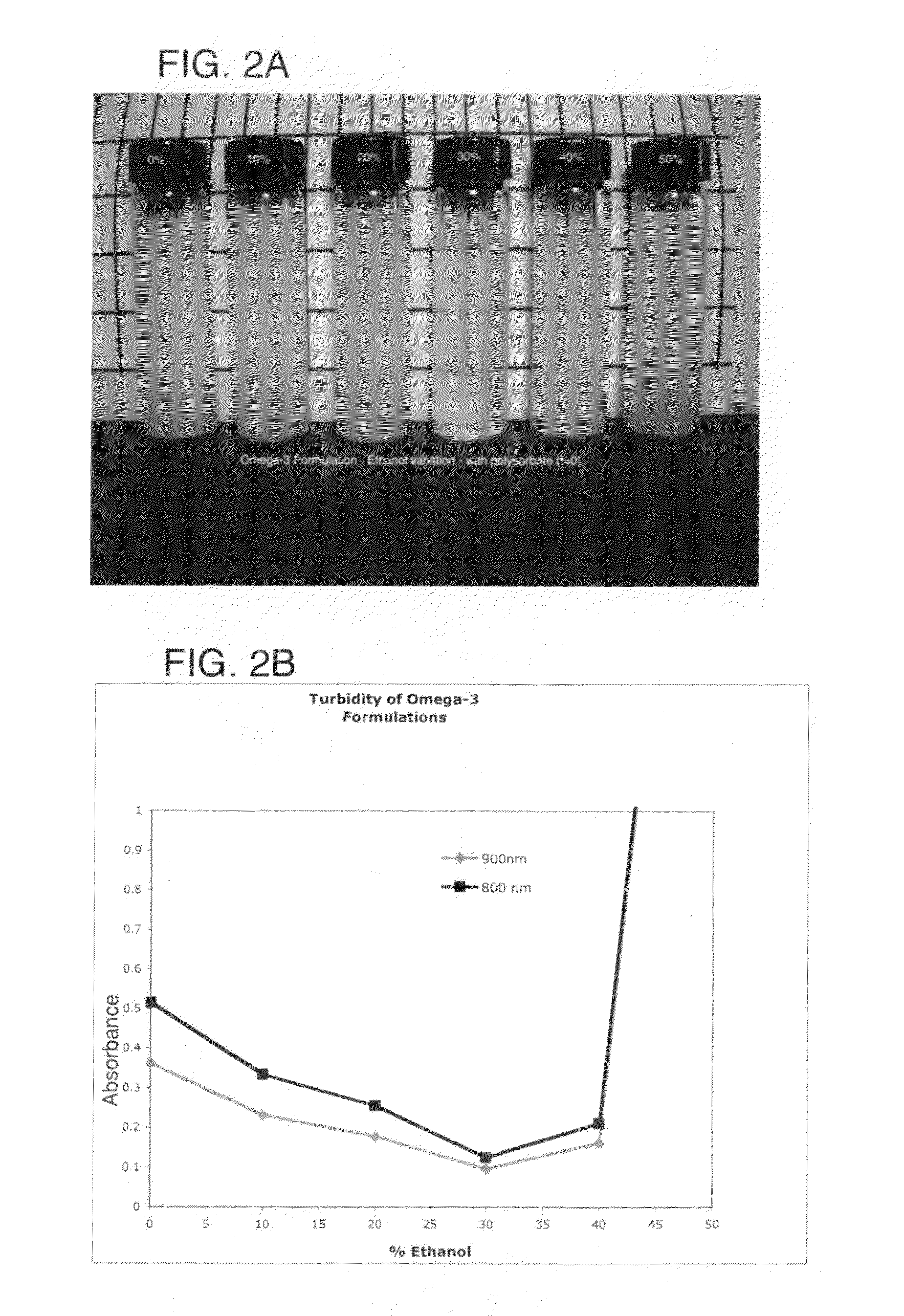

[0095]20 g fish oil (EPAX 1050), 30 g lecithin (Cargill Lecigran), 0.5 g Vitamin E, and 4 ml ethanol were combined in a bottle. The mixture was mixed with heating to 65 C for about 60 minutes until the solution was homogeneous in appearance. This mixture was added to 250 ml of purified water that had been heated to 65° C. and was mixed for 5 minutes. 50 ml samples of this hydrated fish oil lecithin dispersion were combined with suitable volumes of ethanol to produce dispersions containing approximately 0, 10, 20, 30, 40 and 50% (v / v) ethanol. For the purpose of determining the amount of ethanol to add, the small volume already present (from the homogeneous lecithin phase) was ignored. Each dispersion in this series was homogenized (Niro Soavi NS 1001L homogenizer) at approximately 600 bar and 65° C. inlet temperature for 4 passes. Dispersions were then diluted in conditioned water to approximately 3 mg / ml fish oil. FIG. 1A shows a ph...

example 1-2

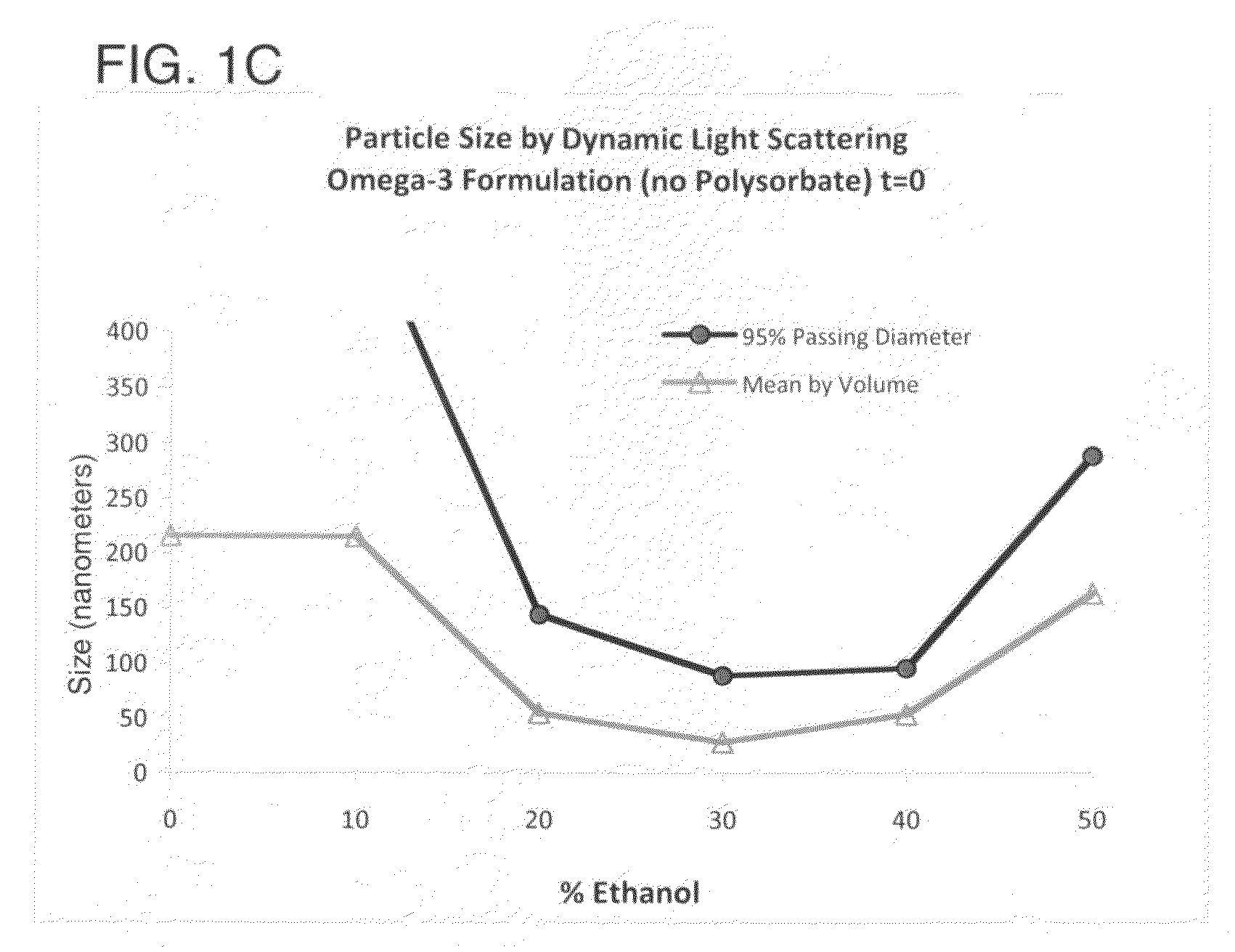

[0096]The HLCV Omega-3 dispersions were made as in Example 1-1, except 1.0 g of polysorbate 80 was added. A photograph of each of these Omega-3 formulations with polysorbate at 0, 10, 20, 30 40 and 50% ethanol is shown in FIG. 2A. Turbidity and particle size distribution data from dynamic light scattering for these formulations are shown in FIGS. 2B and 2C, respectively. As shown, the smallest volume weighted mean diameter, at 30% ethanol, with polysorbate is about 35 nm. FIG. 3 shows a side by side photograph of these Omega-3 formulations at 30% ethanol with and without polysorbate.

example 2

HLCV Dispersion of Essential Oils

[0097]10 g of Lecithin (Lecigran, Cargill or Ultralec, ADM) was hydrated with mixing in 100 ml distilled water and then homogenized at room temperature with 6 passes at approximately 400 bar through a Niro Soavi NS1001L homogenizer to form HLCVs. Polysorbate 80 was added with mixing at a weight ratio of lecithin:polysorbate of 5:1. The dispersion was then diluted to 200 ml using distilled water. The essential oils: thymol (0.7 g), eucalyptol (1.0 g), methyl salicylate (0.65 g) and menthol (0.46 g), were added and mixed to produce an essentially transparent aqueous dispersion of these essential oils. The resulting dispersion was filtered through a 0.2 micron filter. The transparent dispersion was diluted and sweeteners added to produce an ethanol-free essential oil mouthwash. A photograph of two samples of the essential oil dispersion are shown in FIG. 4A, one freshly prepared (t=0) and one stored at room temperature for 12 months (t=12 months). Resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com