Delayed gelling agents

a gelling agent and delay technology, applied in fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problems of limited method in practice, limited wet recovery, and unswept oil left behind, and achieve high brine tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

NA-AMPS Cage Containing PEI / Chromium

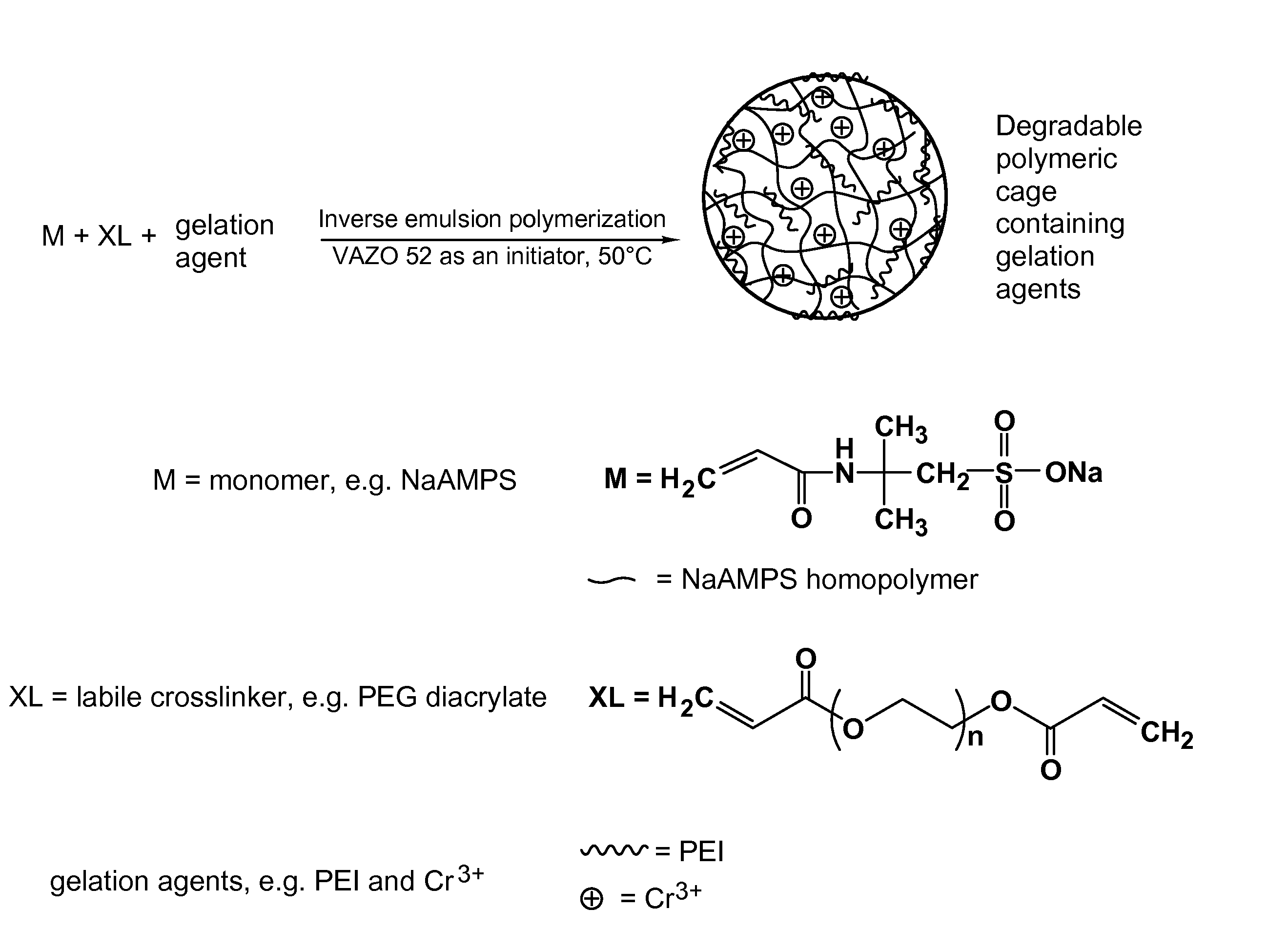

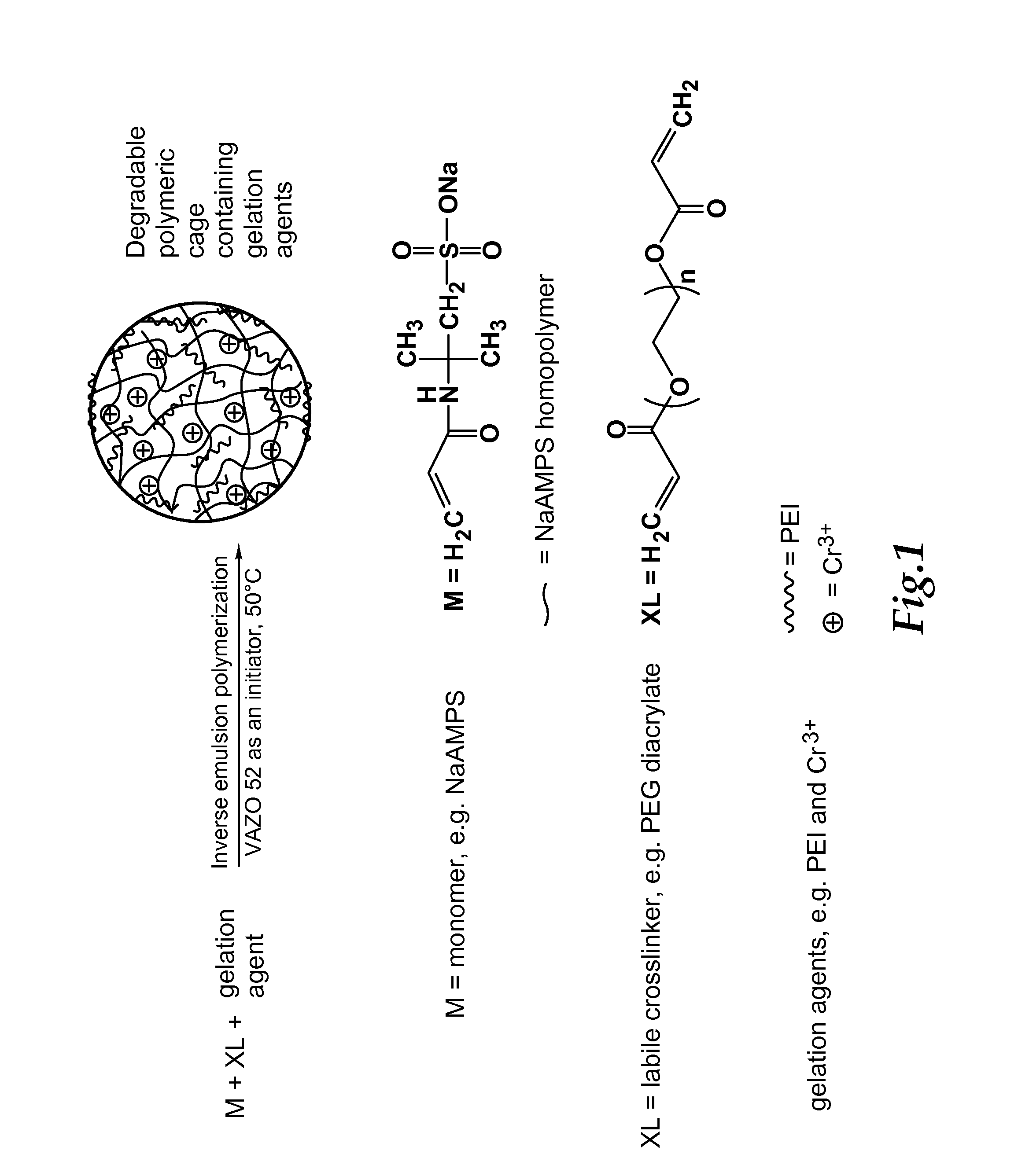

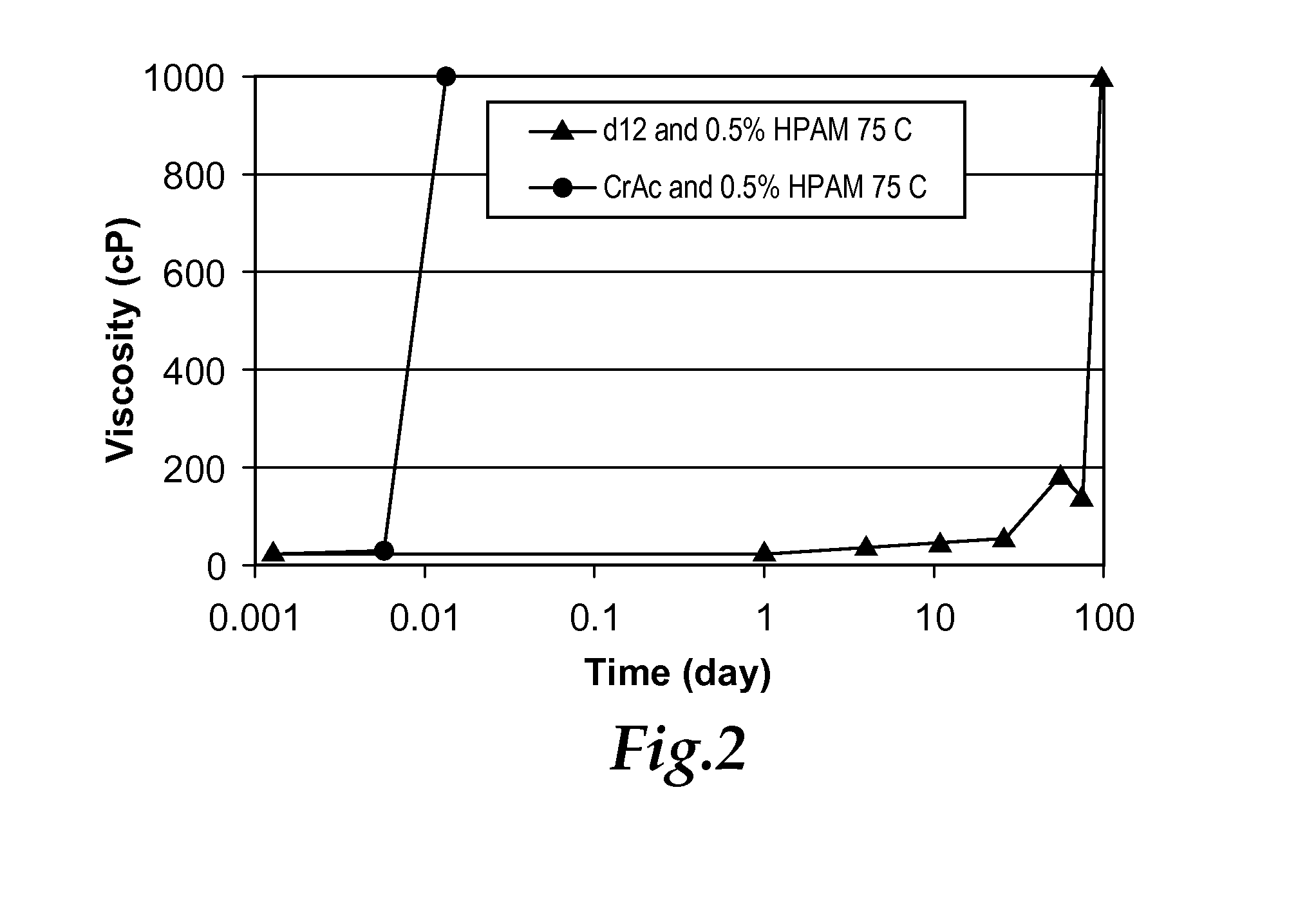

[0053]A representative multivalent cations and cationic polymer-loaded crosslinked polymeric particle or cage, herein referred to as “d12” was prepared using an inverse-emulsion polymerization.

[0054]In such process, an aqueous mixture containing 22 g of 50% sodium 2-acrylamido-2-methylpropane sulfonate (sodium AMPS), 10 g of 50% PEI (2000 Mw), 6.5 g distilled water, 35 mg poly(ethylene glycol) (258) diacrylate, 1.61 g Chromium (III) acetate hydroxide (CH3COO)7Cr3(OH)2 as the dispersed phase (6400 ppm Cr+++) and an oil mixture of 20 g kerosene, 3.2 g Span 83 and 1.8 g polyoxyethylene sorbitol hexaoleate (PSH) as continuous phase were prepared.

[0055]The inverse-emulsion was prepared by mixing the aqueous phase and the oil phase, followed by rapid homogenization using a homogenizer. After adding the emulsion and 20 mg VAZO® 52 as an initiator into a 250 ml flask and purging this mixture with nitrogen for 15 minutes, polymerization was carried out in ...

example 2

NA-Vinyl Sulfonate Cages Containing PEI / Chromium

[0056]In this example, we replaced sodium AMPS with sodium vinyl sulfonate (sodium VS) as a monomer in the synthesis of Example 1 above.

[0057]A representative multivalent cations and cationic polymer-loaded crosslinked polymeric particle, here forth referred to as “d12S” was prepared containing 6400 ppm Cr(III) using inverse-emulsion polymerization. In such process, an aqueous mixture containing 30 g of 25% sodium VS, 8 g of 50% PEI (2000 Mw), 34 mg poly(ethylene glycol) (258) diacrylate, 1.60 g chromium (III) acetate hydroxide (CH3COO)7Cr3(OH)2 as the dispersed phase and an oil mixture of 20 g kerosene, 3.2 g Span 83 and 1.8 g PSH as continuous phase were prepared.

[0058]The inverse-emulsion was prepared by mixing the aqueous phase and the oil phase, followed by rapid homogenization using a homogenizer. After adding the emulsion and 20 mg VAZO® 52 as an initiator into a 250 ml flask and purging this mixture with nitrogen for 15 minutes...

example 3

NA-AMPS Cage Containing PEI

[0059]A representative cationic polymer-loaded crosslinked polymeric particle or cage, herein referred to as “d12-[no Cr]” was prepared using an inverse-emulsion polymerization.

[0060]In such process, an aqueous mixture containing 22 g of 50% sodium 2-acrylamido-2-methylpropane sulfonate (sodium AMPS), 10 g of 50% polyethyleneimine (2000 Mw), 8.1 g distilled water, 35 mg poly(ethylene glycol) (258) diacrylate as the dispersed phase and an oil mixture of 20 g kerosene, 3.2 g Span 83 and 1.8 g polyoxyethylene sorbitol hexaoleate (PSH) as continuous phase were prepared.

[0061]The inverse-emulsion was prepared by mixing the aqueous phase and the oil phase, followed by rapid homogenization using a homogenizer. After adding the emulsion and 20 mg VAZO® 52 as an initiator into a 250 ml flask and purging this mixture with nitrogen for 15 minutes, polymerization was carried out in 50° C. oil bath for 7 hours. VAZO® 52 is a low-temperature polymerization initiator, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid labile | aaaaa | aaaaa |

| composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com