Redundant backlight for liquid crystal displays

a liquid crystal display and backlight technology, applied in static indicating devices, instruments, optical elements, etc., can solve the problems of poor performance of lcd, long time consumption, and the inability to meet the requirements of lighting conditions, etc., to achieve low wattage, reduce heat generation, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

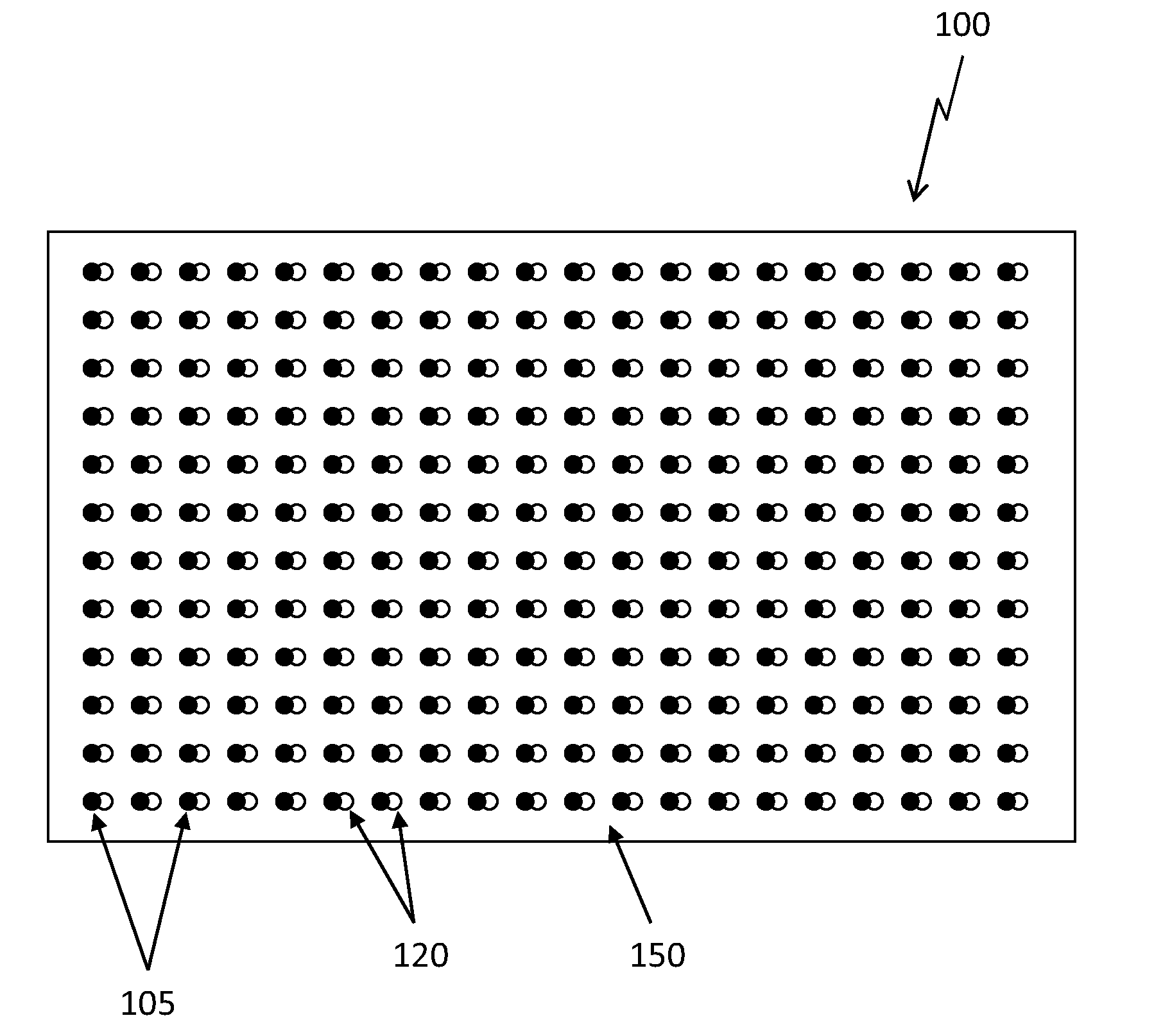

Image

Examples

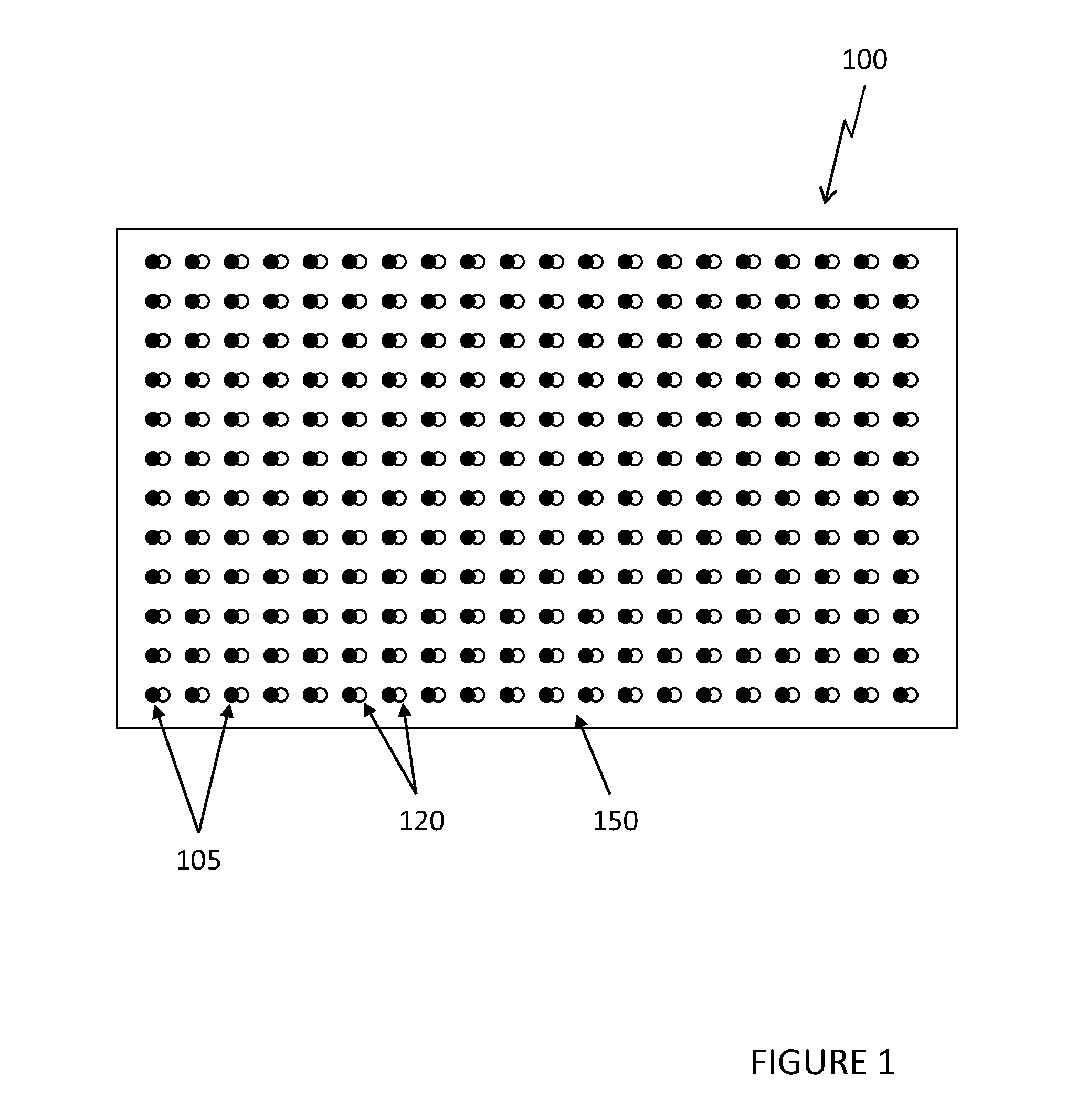

embodiment 200

[0025]FIG. 2A shows an alternative embodiment using an edge-lit LED backlight 200. As known in the art, edge-lit LED backlights place the LEDs along one of the edges of the backlight so that they can provide illumination into the backlight cavity. This illumination is typically directed out of the backlight cavity and through the LCD stack as well as scattered and / or diffused to provide a uniform light distribution. The scattering and directing of the light can be accomplished in a number of different ways (light guides, diffusing sheets, etc.) and the details of this will not be discussed in detail as it is well known in the art. For the edge-lit embodiment 200, the first plurality of LEDs 205 are placed along a first edge while the second plurality of LEDs 220 are placed along the opposing edge of the backlight. This design is beneficial in an embodiment where both sets of LEDs are operated simultaneously as they could combine evenly to create a uniform distribution of light. Agai...

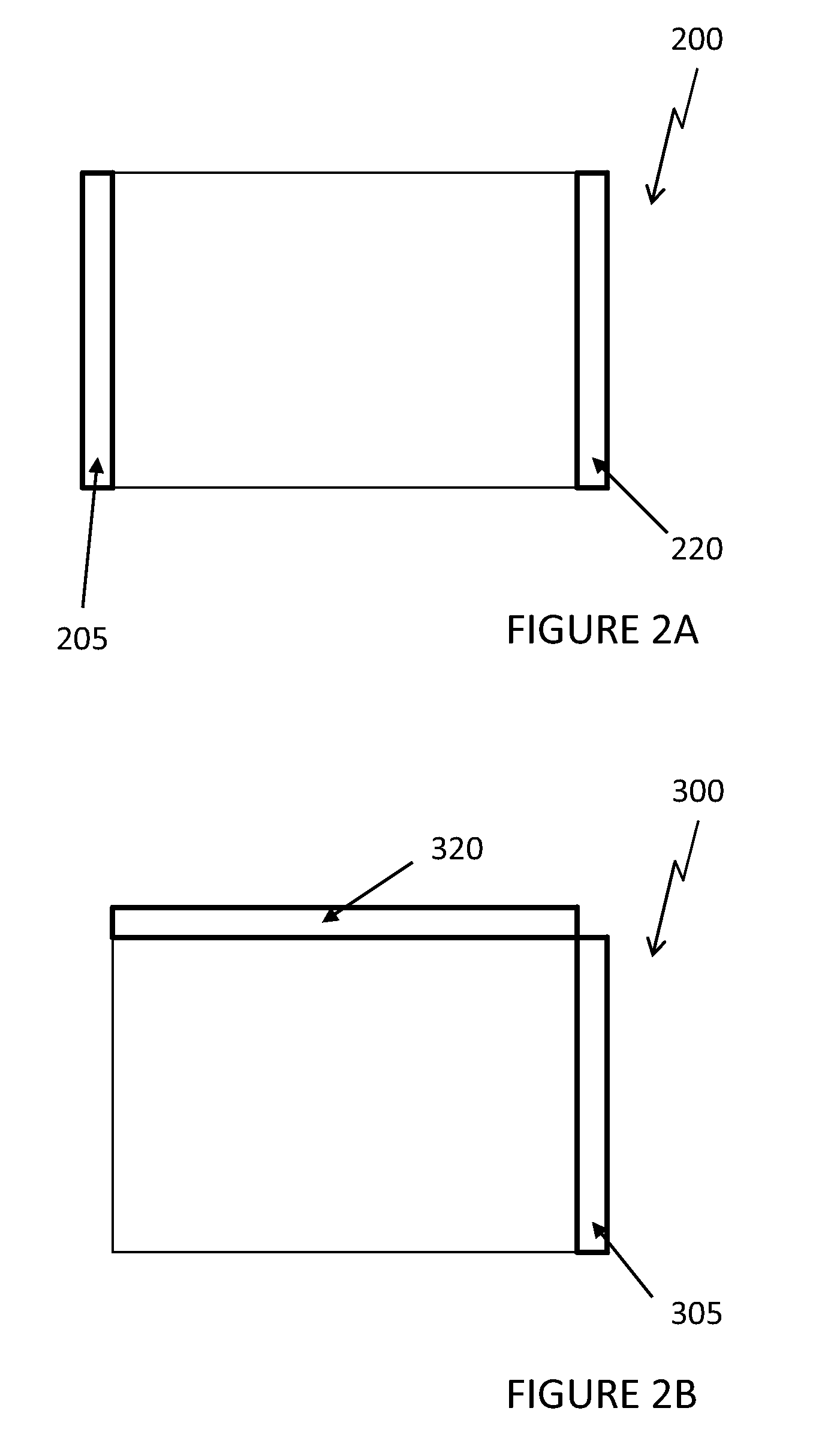

embodiment 400

[0027]FIG. 3A shows a front view for an embodiment 400 using edge LED backlighting for an LCD where the both opposing sides of the LCD are illuminated. Here, a first set of LEDs is comprised of two arrays of LEDs 431 and 430 which are placed on opposing sides of the LCD. Additionally, a second set of LEDs is comprised of two arrays of LEDs 420 and 421 which are placed on opposing sides of the LCD.

embodiment 450

[0028]FIG. 3B shows a front view for an embodiment 450 using a combination of edge LED backlighting and direct LED backlighting. Here, a first set of LEDs may be provided in edge-lit fashion such that LEDs 461 are along a first edge with LEDs 460 along an opposing edge. Additionally, a second set of LEDs 480 is provided in a direct lit fashion.

[0029]FIG. 4 provides an electrical schematic for an exemplary embodiment. A first controller 515 is in electrical communication with a first current source 510 which drives the first set of LEDs 505. A second controller 530 is in electrical communication with a second current source 525 which drives the second set of LEDs 520. The electrical connection 575 provides communication between the first controller 515 and second controller 530. The first and second controllers 515 and 530 may be any type of microprocessor, application-specific integrated circuit, complex programmable logic device, field-programmable gate array, or any other form of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com