Catalytic biomass deconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

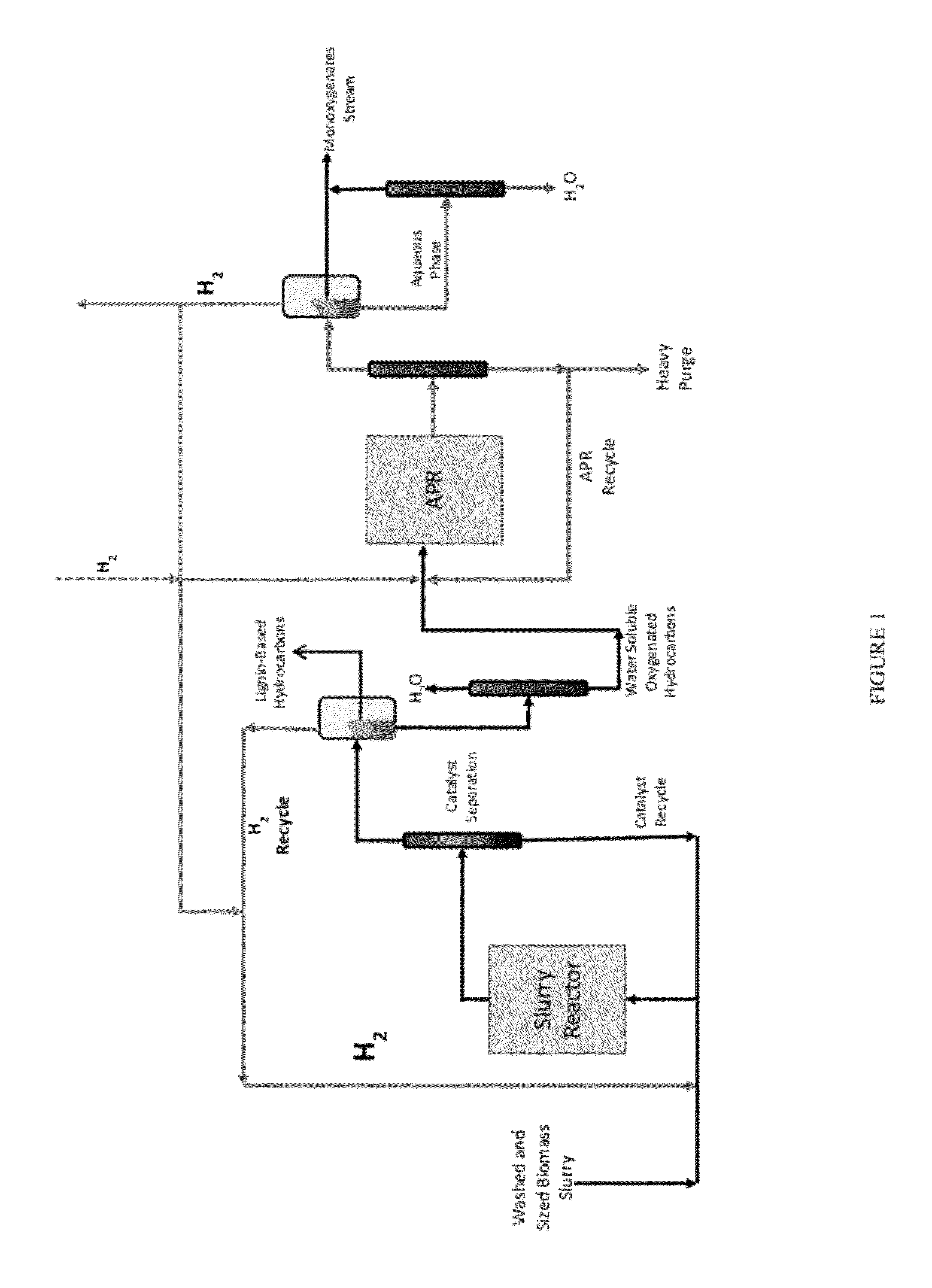

Image

Examples

example 1

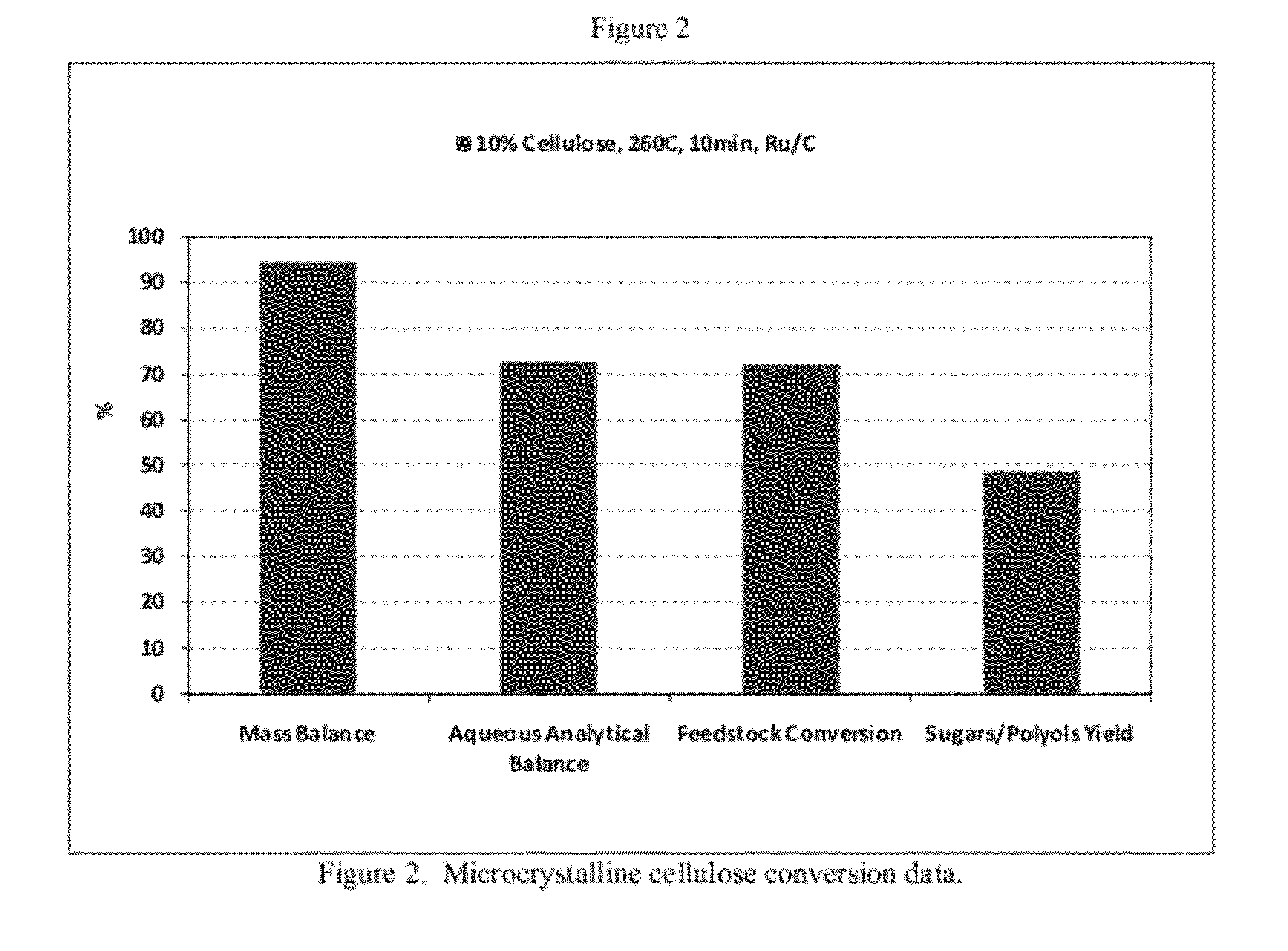

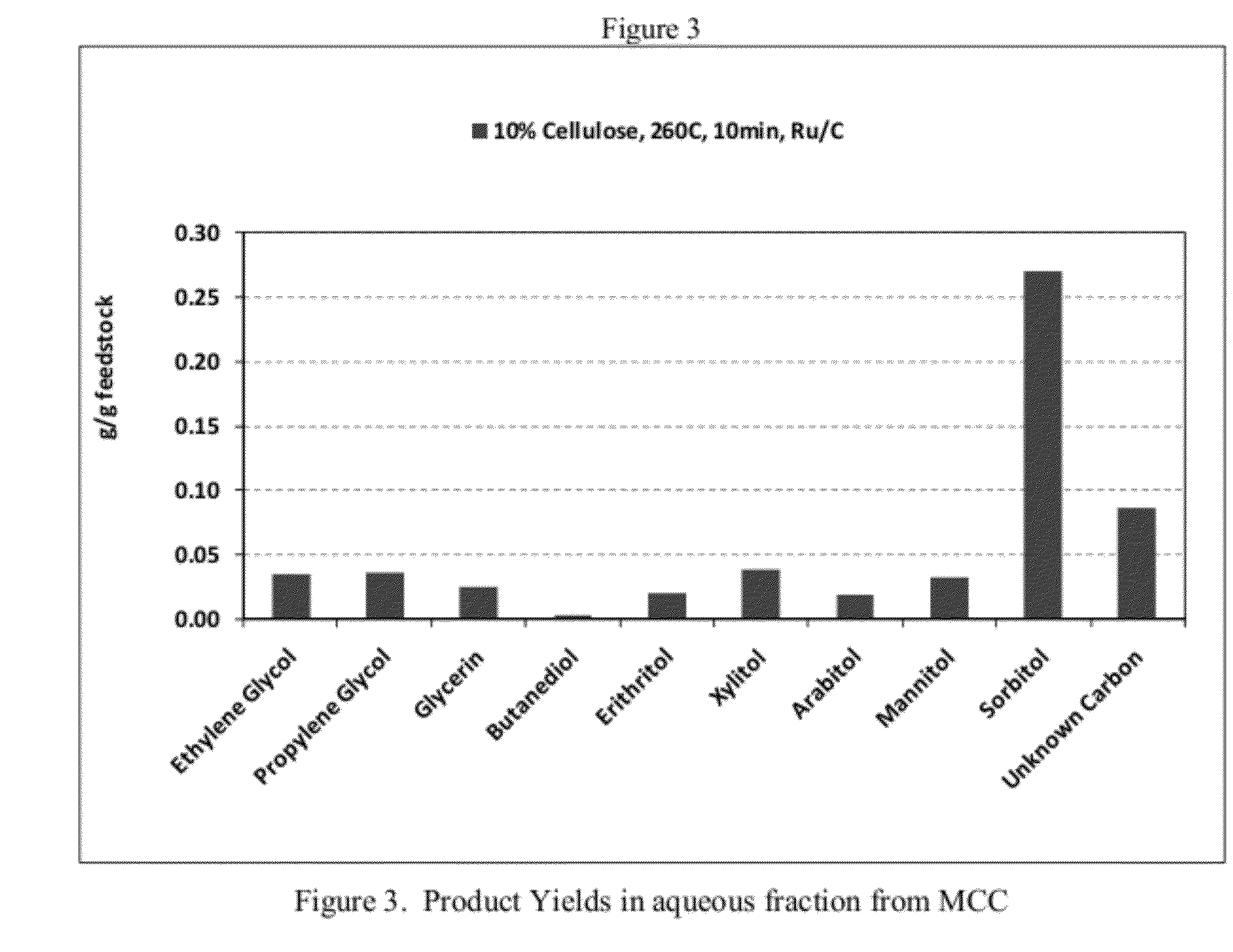

[0083]A biomass slurry containing 10 wt % microcrystalline cellulose (MCC) in water was prepared and converted to a biomass hydrolyzate using ruthenium on a carbon support. Experiments were conducted in a Parr reactor at 240° C. and 260° C., and at variable processing times of 10 and 20 minutes.

[0084]It was discovered that the thermal decomposition of the sugar intermediates is minimized / avoided with the formation of the more stable oxygenates that arise from the hydrogenolysis of the saccharides and polysaccharides. The Ru—C catalyst and short soak times at 260° C. provided high conversion and sugar-polyol yields, with 72% conversion of microcrystalline cellulose (MCC) and a sugars-polyol yield of 48%. A high yield of sorbitol (27 g / g MCC) was found with Ru / C catalyst as illustrated in FIGS. 2 and 3. The mass balance was 94% and aqueous analytical balance was 72%.

[0085]The effectiveness of the longer reaction time (20 min vs. 10 min) is shown in FIGS. 4 and 5. The extended reaction...

example 2

[0086]Several deconstruction catalysts were analyzed for their ability to convert 10% MCC in water to sugars / polyols. Experiments were conducted in a Parr reactor at 260° C. for 10 minutes. As illustrated in FIGS. 6 and 7, platinum improves cellulose conversion and provokes higher extent hydrogenolysis.

example 3

[0087]A biomass slurry containing 10 wt % bagasse was converted to biomass hydrolyzate using the Ru / C catalyst as described in Example 1. Experiments were conducted in a Parr reactor at 245° C. and 260° C. for 10 minutes. FIGS. 8 and 9 provide a comparison of the conversion and product yields for bagasse versus the MCC of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com